TRIGO Opens Cutting-Edge Inspection Facility to Elevate Aerospace Metrology Standards

TRIGO ADR Americas enhances its 3D metrology capabilities with a new Fort Worth facility equipped with advanced AI, scanning, and digital twin technologies to support aerospace quality from prototyping to MRO.

www.trigo-group.com

TRIGO Aerospace, Defense, and Rail (ADR) Americas announces a significant expansion of its advanced 3D Metrology solutions with the launch of a new, cutting-edge inspection facility in Fort Worth, Texas. This strategic investment reinforces TRIGO's position as a pioneer in precision measurement technologies and quality control solutions for the aerospace industry.

Enhanced Customer Value Through Advanced Aerospace Quality Solutions

The new state-of-the-art facility represents a major advancement in TRIGO ADR's capabilities, featuring an impressive array of next-generation metrology equipment designed to support the entire lifecycle of aerospace components. From prototype validation and full-scale production quality control to Maintenance, Repair, and Overhaul (MRO) component verification, the facility embodies TRIGO's commitment to technological excellence.

"In the demanding aerospace industry, precision isn't just a requirement—it's the foundation of success," said Steffen Spell, President at TRIGO ADR Americas. "Our expanded Fort Worth location significantly enhances our capacity and capabilities, delivering faster, more reliable service precisely when and where our clients need it."

Advanced Metrology Solutions Portfolio

The facility showcases TRIGO's comprehensive suite of cutting-edge measurement technologies:

- Laser Tracking Technology: Enabling high-precision, large-scale measurements for structural components, tooling, and assemblies with sub-millimeter accuracy

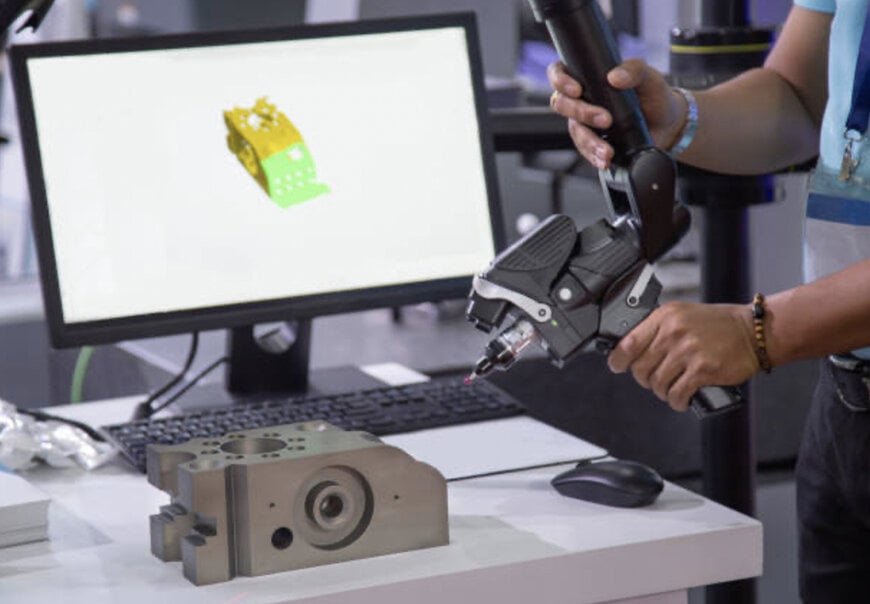

- FARO Arm Inspections: Advanced portable measurement solutions delivering rapid and highly accurate inspections of complex parts and assemblies

- Optical Scanning Systems: Non-contact measurement technology capturing high-resolution 3D surface data with exceptional accuracy

- Automated Optical Inspection (AOI) Systems: AI-powered systems ensuring maximum efficiency and precision in automated inspection processes

- Robotic Arm Inspection Equipment: State-of-the-art automated and adaptable inspection technology

- Coordinate Measuring Machine (CMM) Technology: Ultra-precise dimensional measurement systems

Digital Innovation and Industry 4.0 Integration

With these new technologies, TRIGO ADR Americas is leveraging advanced digital solutions to revolutionize quality management:

- Artificial Intelligence-driven defect detection and analysis

- Digital twin technology for component modeling and verification

- Cloud-based quality management systems for real-time data access

- Advanced analytics for predictive quality control

- Integration with Industry 4.0 manufacturing processes

The facility's technological capabilities ensure manufacturers achieve unprecedented levels of precision in inspections, process optimization, defect detection, and regulatory compliance.

Investment in Future Technologies

TRIGO ADR has announced plans for additional investment in next-generation metrology equipment scheduled for Q2 2025, further cementing its position as a technology leader in the aerospace quality sector.

www.trigo-group.com