www.magazine-industry-usa.com

06

'23

Written on Modified on

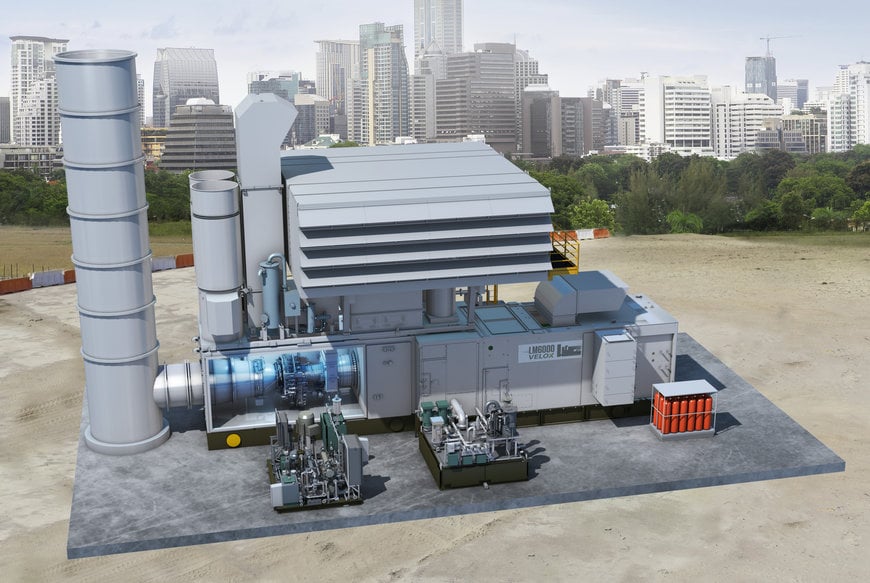

GE VERNOVA DEBUTS FIRST LM6000VELOX PACKAGE

The LM6000VELOX package is built on the philosophy of GE Vernova’s LM2500XPRESS and is factory assembled into simplified modules for a faster and easier site installation and commissioning of LM6000 gas turbines.

Credit: GE Vernova

GE Vernova’s Gas Power business (NYSE: GE) today unveiled the first LM6000VELOX package solution which will be installed at Tennessee Valley Authority (TVA)’s Johnsonville Aeroderivative Plant in Middle Tennessee. The new LM6000VELOX package aims to reduce the installation and commissioning schedule of LM6000 aeroderivative gas turbines by up to 40%, saving up to 4,000 labor hours, with an expected consequent reduction of installation time and total installed costs.

With an installed base of nearly 1,200 LM6000 gas turbines across approximately 60 countries, these units are well-known in the power generation industry for their quick start time of down to 5 minutes to full power, high cyclic life helping to complement intermittent power from renewable sources, and operational flexibility which can help stabilize the grid and reduce the risk of electricity supply shortages. In addition, the turbine in a Singular Annular Combustor (SAC) configuration has the capability to burn up to 100% hydrogen by volume, which can reduce or eliminate CO2 emissions from power delivered by a gas turbine.

GE Vernova’s LM6000VELOX package is built on the philosophy of GE Vernova’s LM2500XPRESS to enhance simplicity and speed of installation. The new package was developed at GE Vernova’s Manufacturing Center in Veresegyház, Hungary, adopting GE Vernova’s most advanced lean methodologies and its benefits include:

GE Vernova’s Gas Power business (NYSE: GE) today unveiled the first LM6000VELOX package solution which will be installed at Tennessee Valley Authority (TVA)’s Johnsonville Aeroderivative Plant in Middle Tennessee. The new LM6000VELOX package aims to reduce the installation and commissioning schedule of LM6000 aeroderivative gas turbines by up to 40%, saving up to 4,000 labor hours, with an expected consequent reduction of installation time and total installed costs.

With an installed base of nearly 1,200 LM6000 gas turbines across approximately 60 countries, these units are well-known in the power generation industry for their quick start time of down to 5 minutes to full power, high cyclic life helping to complement intermittent power from renewable sources, and operational flexibility which can help stabilize the grid and reduce the risk of electricity supply shortages. In addition, the turbine in a Singular Annular Combustor (SAC) configuration has the capability to burn up to 100% hydrogen by volume, which can reduce or eliminate CO2 emissions from power delivered by a gas turbine.

GE Vernova’s LM6000VELOX package is built on the philosophy of GE Vernova’s LM2500XPRESS to enhance simplicity and speed of installation. The new package was developed at GE Vernova’s Manufacturing Center in Veresegyház, Hungary, adopting GE Vernova’s most advanced lean methodologies and its benefits include:

- Enhanced modularity in package mounted air filter including simplified structure for air filter

- Base mounted generator & gearbox which reduces foundation labor

- 50% reduction in number of accessories shipped to site with reduced lifts

- Reduced lube oil flushing with pre-flushed with interconnects and polishing kit

- Improved drive train alignment procedure cutting alignment time in half

- Improved maintainability and accessibility with platforms and ladders

- Improved Cable tray configuration

GE Vernova’s LM6000VELOX package is available in both simple and combined cycle configurations, as either a DLE or SAC (water injected) combustor configuration, and for both 50 and 60 Hertz segments.