www.magazine-industry-usa.com

23

'22

Written on Modified on

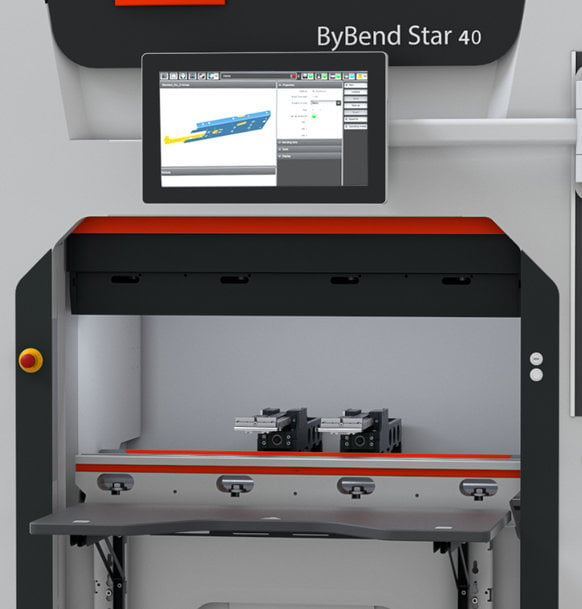

BYSTRONIC: The new ByBend Star 40 and 80, Two mobile bending marvels

The compact mobile press brakes ByBend Star 40 and ByBend Star 80 impress with a new design and a new drive system.

Bending often still means producing small to medium-sized parts on press brakes that are too large. This limits you, because processing bent parts on presses that are too large comes at the cost of time, space, and sometimes also quality.

Advantage: Small

For parts of up to about 1,500 millimeters in bending length and a maximum thickness of 20 millimeters, you do not actually need a large-scale bending station, but rather a small and versatile powerhouse.

The mobility of the two ByBend Star bending machines is a significant advantage over large-format press brakes.

The new ByBend Star 40 and 80 were developed precisely for such requirements – compact, fast press brakes that fit into almost any production environment. Large presses must be placed in a fixed position in production and often take up a lot of space due to their design.

Compact and even more compact

This is not the case with the new ByBend Star 40 and 80: The smallest in Bystronic's range bend as reliably as their big counterparts within the tightest of spaces. Bystronic thus offers an ideal bending solution for production landscapes that are subject to constant change.

The larger of the two small systems: The ByBend Star 80 with 80 tons of press capacity.

Compact and fast

The new servo-hydraulics enable bending speeds of up to 30 millimeters per second. This makes the ByBend Star 40 and ByBend Star 80 three times faster than a large press brake.

80 tons of strength

Compared to the ByBend Star 40, the ByBend Star 80 offers more bending length and more pressing power. This expands the range of applications. On a bending length of around 1.5 meters, the ByBend Star 80 deploys a pressing force of 80 tons. The footprint of the machine is less than 6 square meters.

The ByMotion drive control developed by Bystronic ensures precise acceleration of the upper flank and backgauges.

Easy to operate: Programming the ByBend Vision software on a 21.5-inch screen.

Intelligent functions also save energy

Bystronic paid particular attention to the subject of energy consumption during the development of the entire ByBend Star series: The economical “Dynamic Drive System” drive concept allows for dynamic bending sequences without energy loss. The ByBend Star 40 and 80 supply the exact force required for each bent part.

Added to this are intelligent functions such as the Energy Saver and an automatic start-stop function. Compared to large models, the two ByBend Star press brakes thus offer almost unbeatable energy efficiency throughout the entire bending process.

www.bystronic.com