www.magazine-industry-usa.com

03

'25

Written on Modified on

IMA Schelling reveals the future of cut-to-size technology & CNC machining

BIMA Cx40 now supports 2,050 mm Y-axis range, 85 m/min speed, 36 tool positions, and 23% faster tool changes.

www.imaschelling.com

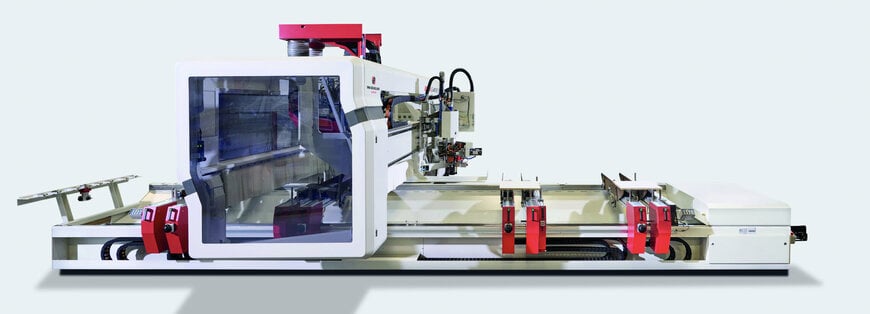

BIMA Cx40 CNC machining centre: new features, new levels of performance

IMA Schelling has recently finished overhauling the BIMA Cx40 for 4- and 5-axis assembly from the ground up and equipped it with several new features. The focus lay on extended machining options along the Y-axis, powerful drilling and edge banding units and clear safety concepts.

At the heart of the system is a modified drive concept in the Y-axis with rack and pinion drive and axis speeds of up to 85 m/min. We have also increased the machining range in the Y direction to 2,050 mm thanks to a redesigned machining support. Two independently operating Y-axes can also be integrated upon request. Another new feature is the standard inclusion of a second Z-axis, which is provided for the drilling unit next to the main spindle; the faster infeed significantly reduces chip-to-chip times. When it comes to 5-axis machining, IMA Schelling offers two approaches: customers can choose between the company's tried and tested 5-axis head (18 kW) or a new alternative (12 kW, HSK 63F). The same applies to the drilling head. Both alternatives can be fully integrated and always offer the optimum solution according to production requirements.

IMA Schelling has now also stepped up the pace when it comes to tool changing – optimised changing positions and an optional second tool changer that moves in the X direction reduce changing times by 23%. It's possible to realise up to 36 tool/unit positions in all. And last but not least, safety remains a critical, key element: dynamic 3D safety via sensor technology, LED field display and optionally available pressure-sensitive safety mats are just some of the measures that enable direct access with simultaneous protection.

Inner corner edging: continuous, automatic, perfectly formed

IMA Schelling is presenting a novel system for edge banding 90° inner corners – directly at the CNC machine. The wood processing experts have two variants in their range: a continuous edge with a small radius and a scribed edge for a sharply defined corner. Both processes are based on the VT 100/100 edge banding unit and can be controlled electronically, making them reproducible with no manual setup required.

The advantage of this approach is a consistent appearance without a set edge. The technology is robust, straightforward and allows continuous edge banding even with complex contours – including variable radii. This opens up a new chapter in CNC machining for furniture manufacturers, interior fitters and fabricators with high aesthetic standards.

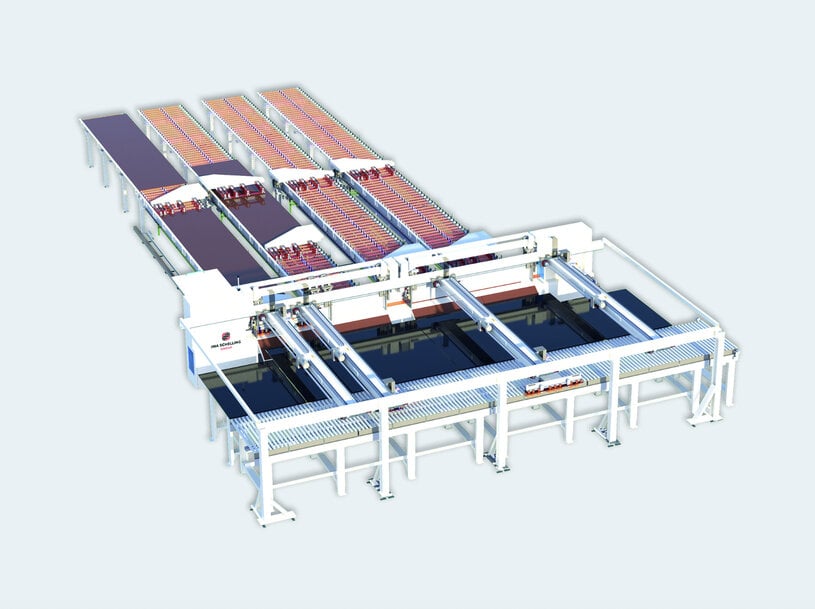

h1 high-performance cutting plant: revised, simplified, logical

After delivering several units, IMA Schelling has further optimised the tried and tested hl 1 saw. What has not changed is the performance. What's gone is any unnecessary complexity. At the heart of the upgrade is the cross-cutting unit, where the return line and overhead guides have been removed to space and components. In their place, two independent feeders per lane (integrated into the roller conveyor) position the material.

Four identical lanes, each 1,300 mm wide, form the basis of the system, which has now been simplified and standardised. Brush tables replace transport belts in the area downstream of the saw and re-cuts are fed back via a circulation carriage – without any extraction carriage or additional conveyor technology. In future, the compact version will only be available with rip-cut and cross-cut saws. Nevertheless, it remains open for full-size and half-size boards. The system standardisation not only reduces set-up times, but also ensures clear processes without any sacrifice in performance.

www.imaschelling.com