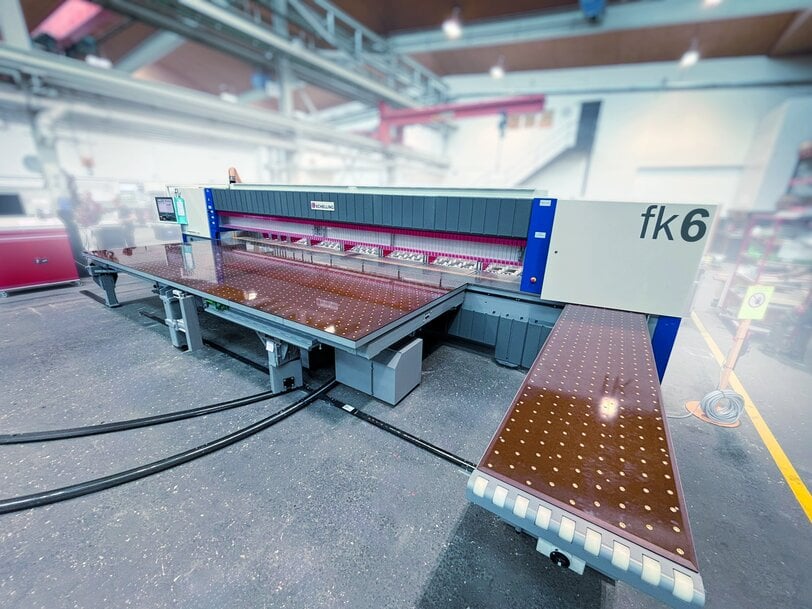

IMA Schelling Delivers XXL Rotary Saw Table for 1.5-Tonne Plastic Sheets

Custom fk 6 saw with 5.8 m movable turntable and double air cushion system enables precision cutting under extreme loads in the US plastics industry.

www.imaschelling.com

What to do when standard solutions reach their limits? When the plastic sheets to be processed are so large and heavy that conventional systems capitulate? This is exactly what a project in the USA was all about. The task: to safely move and cleanly saw sheets weighing up to 1.5 tonnes. The answer: a special version of the fk 6 saw from IMA Schelling Precision - equipped with an XXL rotary table, intelligent support system and double air cushion setup. A machine project beyond the norm.

Things get interesting when 1,500 kg of plastic has to float above the table. Especially when this table also has to be 5.8 m long, 2.2 m wide and move sideways - without showing even a hint of deformation. This was precisely the challenge faced by the experts at IMA Schelling Precision when realising a project for a large plastics processor in the USA. The task: to move large, heavy plastic sheets safely and saw them precisely - without compromise.

Customised production for extreme conditions

Rotary tables are not part of the standard equipment in the fk 6 series - and certainly not in this dimension. The technical requirements included

- Cutting length: 6,300 mm

- Turntable: 5,800 × 2,200 mm, laterally movable

- Material weight: up to 1,500 kg

- Air cushion blower for constant hovering

- Bakelite surface for robust and low-friction panel guidance

The catch: the physical loads on such a long table are enormous. It was already clear during the internal test series that the standard frame could not cope with this. The solution? A completely new support system that intervenes exactly where it counts.

No bending. No sagging.

Two automated side supports, equipped with a rocker lever mechanism, give the turntable the backbone it needs under full load. During movement, the supports retract to allow the table to move freely. In the end positions, they extend, reach under the frame - and reliably return the table to a horizontal position. The result: a permanently flat surface - a basic requirement for a functioning air cushion system.

Air cushion table 2.0

The table was also equipped with a second blower. The advantage: even with slightly uneven tops, the floating remains constant. The air cushion supports without swaying - even with critical material. A real boost for handling large panels, without effort, without grinding, without delays.

The customised fk 6 has now passed all internal tests and is currently being shipped to the customer in the USA. There it will play a key role in the processing of technical plastics in the future.

About the fk 6

The fk 6 panel dividing saw from IMA Schelling Precision is designed for cutting plastic and composite panels up to 120 mm thick. With 27 kW motor power, a robust design and 99.5 % splinter-free operation, it offers a clean, fast and durable solution for industrial applications.

www.imaschelling.com