www.magazine-industry-usa.com

02

'21

Written on Modified on

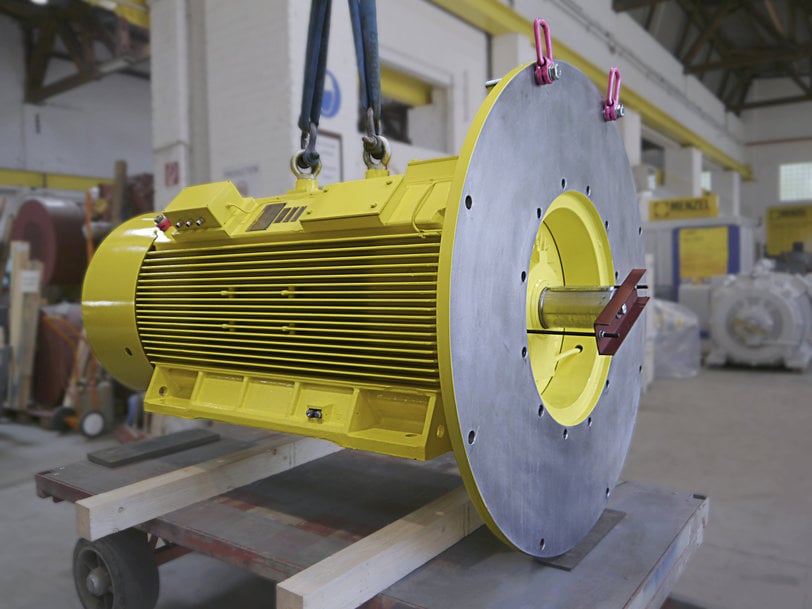

Pump motor with special flange for chemical plant

Menzel Elektromotoren has realized an unusual motor configuration to help out a customer: the operator of a large chemical plant needed a replacement for a failed pump motor.

It seemed difficult, at first, to find a machine able to accommodate an existing oversized pump flange dimension. Only the family-run company Menzel offered a size 400 motor that matched the performance profile and was light enough. The Berlin-based manufacturer converted a stock, IM B3 type motor (foot mounting) to type IM V1 (vertical flange mounting). For this purpose, the drive-end bearing seat was converted for the installation of a thrust bearing.

Menzel also manufactured the special flange in-house and adapted it to the shaft, which could only protrude 120 mm from the flange. Menzel prepared the motor for quick installation at the customer’s site, shifting the main terminal box to the most accessible position and mounting a cable entry that could be readily adapted to the existing cable diameter on site. By installing both the heater and PT100 connections in one auxiliary terminal box, Menzel was able to save one terminal box. The motor, which is now successfully in operation in the customer’s plant, has a rated output of 315 kW and a nominal voltage of 5000 V. It features the cooling type IC 411 and an IP55 protection rating and weighs 4900 kg.

More information about squirrel-cage motors with cooling type IC 411 is available at https://www.menzel-motors.com/squirrel-cage-motor/ic411-ic416/

www.menzel-motors.com