www.magazine-industry-usa.com

24

'19

Written on Modified on

INDUSTRY 4.0 AND IOT EXPAND SMART SENSOR APPLICATIONS

Although sensors have been important devices in manufacturing and process plants for many years, today they have a particularly crucial role to play. Thanks to a number of enhanced features, matched by high levels of flexibility and increasingly compact dimensions, the latest smart sensors have become stars in the world of Industry 4.0 and the Internet of Things (IoT). For users, smart sensor evolution means greater profitability provided by more productive assets.

This thinking is confirmed by Bruno Kim, Marketing Manager at KEYENCE. “A smart solution may bring several benefits; for example, inspection reliability using such a system becomes undeniably superior to that performed by a human operative,” he says. “After all, automated inspection is not subject to human bias, thus ensuring higher repeatability and process speed. Reduced downtime is also of relevance, thanks largely to an evolution in technology that has increased the ruggedness of inspection instruments to suit harsh environmental conditions on the shop floor. As a result, productivity is enhanced. Time and expenditure reductions also appear on the list of benefits, as much higher productivity means less labour costs.”

KEYENCE has great confidence in its vision system for surface inspection. The company has recently released its multi-spectral technology, which includes lighting in several spectrums, in order to obtain the best application stability and contrast. Featuring a method of capture that is unique in the market, clients benefit from a rugged design which provides inspection results free from subjective interpretation bias.

Measurement reliability, downtime reduction and faster calibration, asset costs and time savings; all these benefits provided by smart sensors are connected in the opinion of Gustavo Takizawa, Application Engineer at HONEYWELL Sensing and IoT Division. “However, I would say that measurement reliability is the key to smart sensor success,” he states. “Once sensor measurements are reliable, the benefits provided imply less maintenance requirements since it is possible to predict system anomalies and, therefore, increase asset [employee] efficiency and, at the same time, reduce costs.”

HONEYWELL uses several technologies in its sensors dedicated to the measurement of pressure, humidity, temperature and position, including MEMS (Micro Electro Mechanical Systems) and ASIC (Application Specific Integrated Circuits), with the objective of collecting data accurately and reliably. The company’s SMART (Superior Measurement. Accurate. Reliable. Thinking.) Position Sensor, for example, is a highly reliable ASIC using an array of integrated circuits to detect magnetic fields (Hall effect sensors) for enhanced object position sensing.

According to ROCKWELL AUTOMATION Product Manager, Maurício César Brichesi Filho, the ROI calculation for smart sensor applications will be based on the previous conditions of the equipment/line where they are installed. For example, factors such as downtime caused by equipment failure, reduced product quality and lower OEE (Overall Equipment Effectiveness) all need to be included in the equation. “Smart sensors are capable of reducing maintenance costs by reducing the equipment/line MTTR [Mean Time To Repair],” he says. “They are capable of providing contextualized information of actual field conditions in real time, so the end user is able to make fast and efficient decisions.”

The smart sensor technology of ROCKWELL AUTOMATION is implemented by means of three components: advanced diagnostics sensors (IODD Advanced); IO-Link technology to deliver more data to the control system; and the advanced integration of sensors and controllers, a unique feature in the market.

Industry 4.O and IoT

“With Industry 4.0, the main issue is the potential for establishing communications between the sensor and the information network, plus process automation,” states Kim. “As a particular point of note, we’ve been noticing intense market interest in automatic inspection solutions.” Kim finds it difficult to predict the type of sensor that will command the biggest market share, because that depends on each specific application. “Considering that the market has been looking for inspection automation options, it is possible that sensors related to this kind of application will play a major role from now on,” he says.

“Industry 4.0 and the IoT influence and demand very decisive growth in the smart sensor market, since the world needs process optimization, assets and increased profitability,” says Takizawa. “Smart sensors are basically the heart of Industry 4.0 and the IoT; they play a major role in fast, efficient and reliable data acquisition.”

Of course, growing competition in worldwide markets calls for technology updates on a yearly basis. “The combined sensor is likely to play a major role in the next few years”, hopes Takizawa. “This kind of sensor is capable of collecting several types of data. An example of a combined sensor is our HumidIcon, which combines temperature and humidity in a single sensor, with a digital output for communication. If a sensor is capable of combining information (pressure, humidity, temperature, position, etc.), equipment space will be more optimized, easing the path from design concept to reality.”

Similarly, Brichesi reiterates that the growth of Industry 4.0 and the IoT is based on the modernization of sensors and actuators. “According to the ISA-95 standard, sensors and actuators are in level 0, and are responsible for providing reliable information to the analytical and management systems,” he says. “If bad quality information is provided, the performance of analytical technologies and ML [Machine Learning] will be affected.” Brichesi adds that the main applications are in analogic technology (pressure, temperature, distance) which, besides enabling productivity, reduce the cabling costs of field devices. For this reason, Brichesi is convinced that analogue sensors will play a key role, since it is easier to implement this type of sensor than digital counterparts such as distance, colour and condition sensors.

Future

Which industrial segment will have the greatest demand for smart sensors in the near future is considered, for the time being, a guessing game by Kim. “Even if several companies come up with similar products, the way they are made will be, in most cases, quite distinct,” he states. “I believe that all active players in product manufacture are candidates to drive higher demand for such items. The principle which must be considered is that every product submitted for processing is subject to inspection, to make sure it is within quality parameters”, Kim explains.

According to Takizawa, agriculture, energy and medicine will be demanding more and more smart sensors as the technology keeps evolving. “A combine harvester, for example, may use position sensors, IMUs [Inertial Measurement Units], pressure, temperature, speed and current sensors, GPS, and several other types,” he says. “Furthermore, these markets demand real-time monitoring of the data provided by such sensors, so that equipment operators can make fast decisions. The medical and energy markets are those demanding the most up-to-date technologies capable of providing high-accuracy data collection, mainly in healthcare, so that a doctor may analyse data from several patients in real time. Additionally, trending this data will increase system reliability and decrease eventual failures.”

Brichesi predicts that the industrial segments set to take most advantage of this technology will be food and beverage, automotive and tire manufacturing, as well as general manufacturing. “These segments already use several sensor types across their industrial facilities that are connected to conventional I/O cards,” he explains. “The lack of information to the user caused by this type of set-up creates serious consequences, such as plant shutdowns and decreased operational reliability. However, by applying the latest sensor technology, they will experience a marked increase in production and reliability.”

According to a survey carried out by Markets and Markets, an Indian company specializing in quantified market research, the industrial sensor market was valued at US$16 billion in 2018 and is likely to reach US$21.6 billion by 2023, an annual growth rate of 6.16%. The survey points out that this increase is being propelled by growing demand for Industry 4.0 and IoT strategies, by the surging wireless sensor market and the burgeoning demand for industrial robots.

Smart sensors are expected to evolve quickly, particularly in size, performance and cost. As a result, the use of smart sensors will become more widespread as the IoT improves and renders important data transmission safer. This progression will lead further industries to adopt smart sensor technology.

Author: Kip Hanson

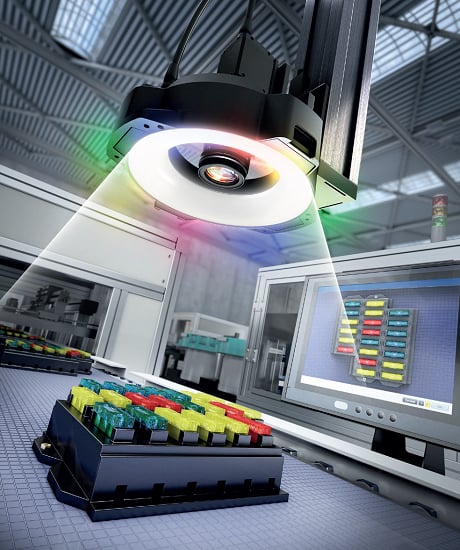

CV-X SERIES MULTISPECTRUM: FLEXIBILITY AND RUGGEDNESS IN VISUAL INSPECTION.

This series uses Lumitrax™ technology, where the final image is obtained by superimposing several images captured at various lighting angles.

CV-X Series Multispectrum uses an innovative inspection algorithm. High-speed monochrome cameras are used together with eight-colour lighting, a configuration that promotes accurate applications, even with subtle hue variations.

This series also uses Lumitrax™ technology, where the final image is obtained by superimposing several images captured from multi-angle lights, in order to minimize reflex and maximize contrast. Such capability enables users to easily generate images that would otherwise require a lot of experience and editing time.

In short, this vision system offers the most advanced hardware and software, providing more flexibility and ruggedness in visual inspection applications, while simultaneously offering intuitive, simple operation.

www.keyence.com

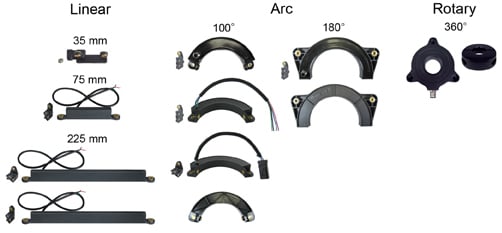

SMART POSITION SENSOR

This is a combination of an ASIC (Application Specific Integrated Circuit) and an array of MR (magnetoresistive) sensors.

The Smart Position Sensor is one of the most adaptable and lightweight sensors available on the market, enabling highly accurate motion control, and enhanced operational efficiency and safety.

A simple non-contact design eliminates mechanical failure mechanisms, reduces wear and tear, improves reliability and durability, and minimizes downtime.

The Smart Position Sensor is a non-contact solution for absolute position sensing with enhanced accuracy.

These sensors use a combination of an ASIC (Application-Specific Integrated Circuit) and an array of MR (magnetoresistive) sensors to accurately and reliably determine the position of a magnet attached to a moving object, so that its position can be determined or controlled.

www.honeywell.com

NEW PHOTOELECTRIC SENSOR FOR DEMANDING APPLICATIONS

This high-performance sensor provides long-distance detection and increased environmental tolerance for industries such as food and beverage, material handling, and packaging.

A pillar of Industry 4.0, the Allen-Bradley 42AF RightSight M30 photoelectric sensor from Rockwell Automation is built with improved environmental resistance and long-distance detection in a mid-sized, right-angle housing, and offers the flexibility and performance required for a wide range of demanding applications.

Developed with IO-Link capability, these sensors are easily integrated into automation architectures, providing data and diagnostics directly from/into a control system to help minimize downtime and increase productivity. Using this capability, the sensor can provide information such as signal strength, location, proximity alarms and timing functions, which increase operational efficiency and decrease plant downtime. The 360-degree high-visibility LED power and status indicators further assist in set-up, monitoring and troubleshooting.

www.rockwellautomation.com