Mitsubishi Electric Develops World's First Metal Corrosion Sensor Designed for Mounting on Printed Circuit Boards

Detects metal corrosion caused by exposure to the atmosphere, helping prevent equipment failure.

Mitsubishi Electric Corporation (TOKYO: 6503) announced that it has developed what is believed to be the world's first* compact metal corrosion sensor small enough to be mounted on printed circuit boards. The new sensor utilizes metal corrosion monitoring technology developed by Mitsubishi Electric that detects the degree of corrosion of metal components caused by corrosive gases such as sulfur compounds in the atmosphere.

The deployment of multiple sensors with different levels of corrosion resistance allows the degree of corrosion to be detected in stages, helping to prevent equipment failure. Mitsubishi Electric plans to deploy the new technology across its own industrial equipment portfolio.

Key Features

World's first compact metal corrosion sensor that can be mounted directly on printed circuit boards

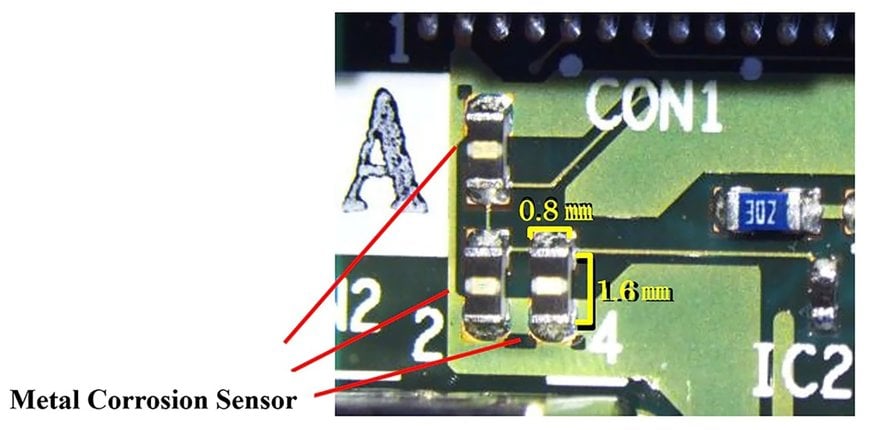

- Its simple structure, incorporating a thin metal film and resistors and measuring just 1.6mm x 0.8mm, enables the sensor to be mounted directly on printed circuit boards and easily deployable across a wide range of products containing these, such as industrial equipment; this is believed to be a world-first.

- Detection under conditions more closely matching the environment inside the equipment eliminates the need to install additional measuring instruments such as external sensors.

The degree of corrosion can be detected in stages

- The progress of any corrosion can be gauged by measuring the increase in electrical resistance of the corrosion sensors.

- The resistance of the corrosion sensors can be adjusted by changing the composition and thickness of their metal content.

- The deployment of multiple sensors with different levels of corrosion resistance allows the degree of corrosion to be detected in stages, helping to prevent equipment failure.

When metals are exposed to corrosive gases in the atmosphere, corrosion progresses from the surface to the inside and turns into rust. Since the electrical resistance of rust is tens of thousands of times higher than that of metal, the progress of any corrosion can be gauged by measuring the increase in electrical resistance.

www.mitsubishielectric.com