www.magazine-industry-usa.com

16

'25

Written on Modified on

Comau Builds In-House Dry Room to Develop Cell Manufacturing Solutions

The new moisture-controlled lab in Italy will support next-generation battery cell research, process validation, and innovative customer projects across Europe.

www.comau.com

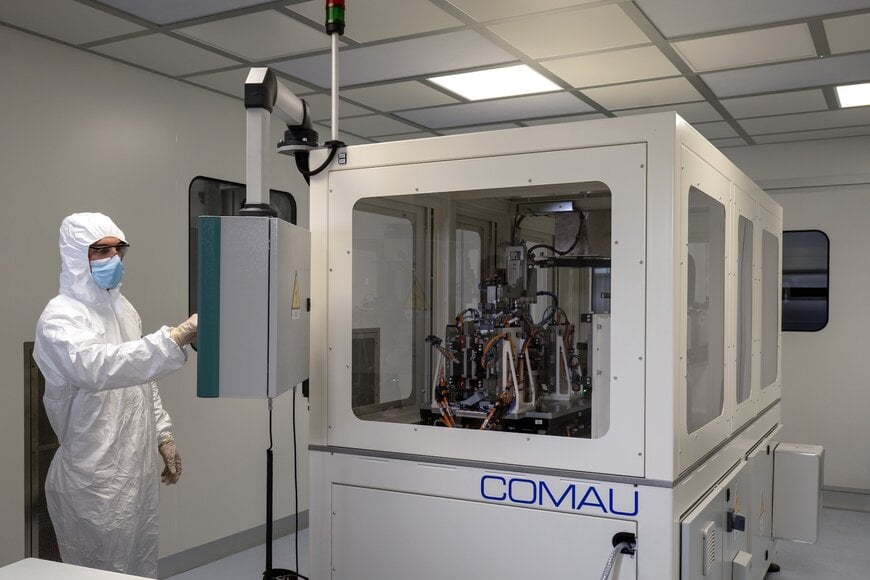

Comau has built a proprietary, fully-equipped dry room laboratory at its Italian headquarters in Grugliasco to develop and test the cell manufacturing equipment the company has already developed. It will also be used to test new machines targeting Lithium-Ion and Lithium Metal cells, in order to access solid state technologies as a further step towards next-generation and post Lithium batteries. The fully equipped dry room strengthens the company's presence in the electrification sector and enhances its end-to-end battery solutions portfolio. It also allows Comau to better support customers as well as validation activities.

The new dry room, for which Comau has invested close to €1 million, aims to facilitate and speed the development and commercialization of new technologies. It features three proto-test spots (2 of which in -40° dew point (DP) and 1 in -50°DP). It will be openly available to customers, universities and associations in addition to Comau’s Global Competence Center team which at present consists of more than 40 engineers. Among the different technologies used for the different processes, the laboratory features Comau’s Racer 5 Sensitive Environments robot.

In terms of processes, the dry room will facilitate Comau’s development in electrode manufacturing, cell assembly and formation aimed primarily to study and validate solutions for solid state and next generation battery production technologies. Moreover the -50 DP room will allow Comau to work with moisture-sensitive materials such as Lithium metal and electrolytes.

Comau’s dry room also is key for the company to proceed with the optimization of ongoing cell assembly developments including notching (both laser and mechanical) and stacking technologies, to name a few.

Comau’s longstanding ability to pioneer new technologies while adapting to different market dynamics is further aided by a network of seven dedicated Innovation and Competence Centers that are strategically located in key markets including Italy, France, China, India and the United States. These global Centers are integral to the company’s ongoing commitment to advancing industrial automation technologies and supporting customers anywhere in the world.

www.comau.com

The new dry room, for which Comau has invested close to €1 million, aims to facilitate and speed the development and commercialization of new technologies. It features three proto-test spots (2 of which in -40° dew point (DP) and 1 in -50°DP). It will be openly available to customers, universities and associations in addition to Comau’s Global Competence Center team which at present consists of more than 40 engineers. Among the different technologies used for the different processes, the laboratory features Comau’s Racer 5 Sensitive Environments robot.

In terms of processes, the dry room will facilitate Comau’s development in electrode manufacturing, cell assembly and formation aimed primarily to study and validate solutions for solid state and next generation battery production technologies. Moreover the -50 DP room will allow Comau to work with moisture-sensitive materials such as Lithium metal and electrolytes.

Comau’s dry room also is key for the company to proceed with the optimization of ongoing cell assembly developments including notching (both laser and mechanical) and stacking technologies, to name a few.

Comau’s longstanding ability to pioneer new technologies while adapting to different market dynamics is further aided by a network of seven dedicated Innovation and Competence Centers that are strategically located in key markets including Italy, France, China, India and the United States. These global Centers are integral to the company’s ongoing commitment to advancing industrial automation technologies and supporting customers anywhere in the world.

www.comau.com