www.magazine-industry-usa.com

16

'19

Written on Modified on

WMFTG offers optimum way of matching hose material to pumped fluids

Watson-Marlow Fluid Technology Group (WMFTG) is now offering a unique way of matching Bredel hose material to the actual fluid being pumped, an activity that, if completed correctly, is proven to reduce costs.

Optimised pump life and efficiency depends on selecting the correct hose material in tough fluid-handling applications. Matching the peristaltic hose material to the pumped fluid can reduce downtime, cut production costs and save energy in pumping operations that involve viscous and abrasive fluids.

Bredel pump users are now able to choose the correct chemically compatible hose material, ensuring long hose life, repeatable flow rates and greater uptime in their process.

Each Bredel hose features a precision-machined natural rubber outer, with intermediate compound layers, bonded by multiple nylon cord reinforcements to add strength and flexibility. However, it is the important inner hose material that must be selected to match the fluid.

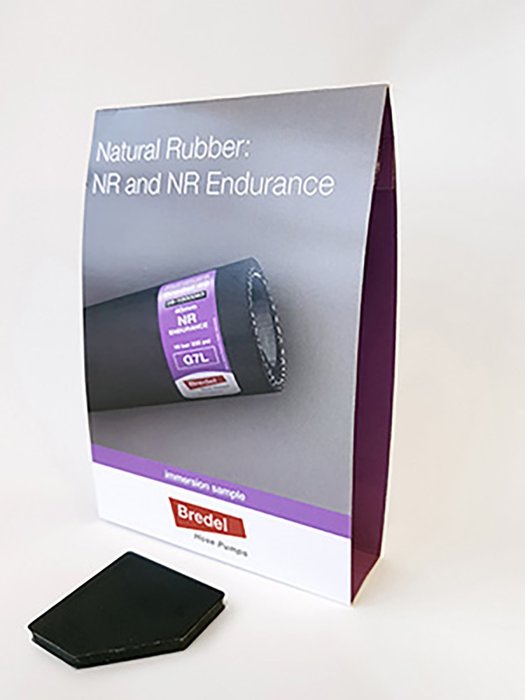

Bredel hose bore materials include NR, NR Endurance, EPDM, NBR/NBR for Food, F-NBR and CSM, and each has its own attributes for abrasion resistance, along with differing suitability for oils and greases, acids, alcohols, strong oxidising products and many other substances.

WMFTG sample packs carry complete hose material data, including temperature resistance, as well as instructions for immersion tests.

The packs are another step to reinforce the strengths of the Bredel peristaltic hose pump range and WMFTG’s guaranteed support for customers at every stage of pump and hose selection in the environmental, food and beverage, chemical, mining and other process industries.

www.watson-marlow.com