www.magazine-industry-usa.com

09

'19

Written on Modified on

Technology Excellence for the future of machine tool manufacturing

DMG MORI will impress visitors at Chicago Innovation Days with innovative machining technologies.

- US premiere ALX 2000: Reliable and cost-efficient turning processes

- US premiere DMP 70: Highly dynamic production machine with a footprint of 46.28ft²

- 5-axis Excellence: Complete machining for more productivity

- ADDITIVE MANUFACTURING: Bundled competence at the ADDITIVE MANUFACTURING Excellence Center

- Technology Excellence: Experience and competence for leading industries

- DMQP: Perfectly coordinated peripherals and accessories from one source

During this year’s Chicago Innovation Days in Hoffman Estates from May 13th - 16th, 2019, DMG MORI will once again demonstrate latest trends and innovations in machine tool manufacturing.

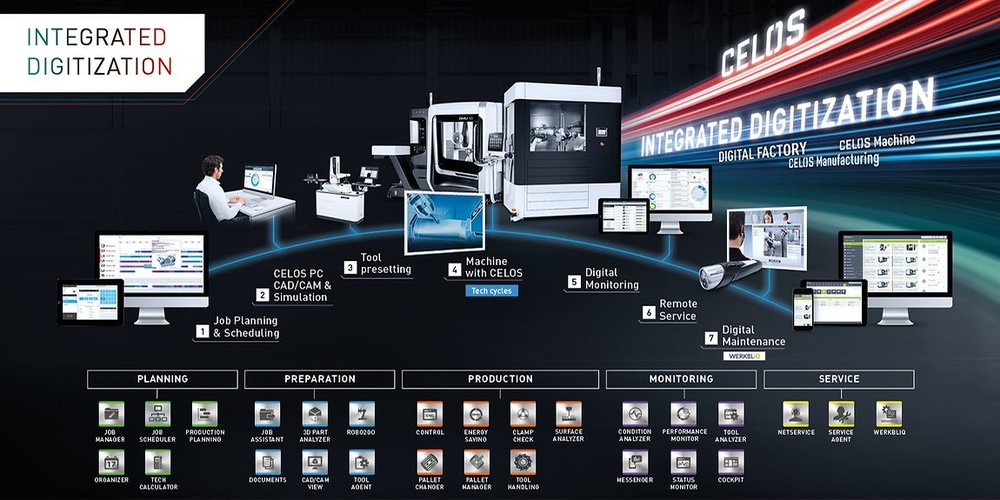

The event highlights will be INTEGRATED DIGITIZATION for planning, preparation, production, monitoring, and service, AUTOMATION SOLUTIONS for competitive manufacturing, and ADDITIVE MANUFACTURING with four process chains in the powder bed and with the powder nozzle.

Additionally, DMG MORI will present their TECHNOLOGY EXCELLENCE in the leading sectors of aerospace, automotive, die & mold, and medical. A special focus on the machine tool manufacturer’s 35-year history in 5-AXIS EXCELLENCE and two US premieres – the ALX 2000 and the DMP 70 – completes the event.

Integrated Digitization: Heading towards the Digital Factory with “Open Connectivity”

The trend towards industrial digitization is fundamentally altering the framework conditions for metal cutting production technology. DMG MORI’s machines have been offering digitization solutions since 2013 with the CELOS app-based control and user interface. At the same time, DMG MORI has been consistently expanding the range of solutions it offers to create an open ecosystem for the digital factory.

In addition, DMG MORI is increasing its portfolio of CELOS services with intelligent software solutions and connective hardware. Open Connectivity includes digital IoT services and products to integrally network processes and machines with one another. Additionally, DMG MORI has established the CELOS Club, which offers customers unique solutions on their path to Industry 4.0 and IIoT.

US premiere: ALX 2000 Reliable and cost-efficient turning processes

Modern equipment options, compact dimensions, and a high level of automation all contribute to the efficiency of a turning machine. DMG MORI has considered this in the development of the ALX series to meet the high demands of serial production in the automotive and other sectors.

The ALX 2000, a US premiere that DMG MORI produces locally in Davis, is a stable, dynamic, and compact turning machine that combines excellent standards from a max. spindle speed of 4,500 min-1 to the BMT turret with twelve powered tools and tailstock. In addition, the ALX 2000 offers a high degree of automation thanks to the optional gantry loader, a deciding factor for cost-effectiveness in production.

US premiere: DMP 70 Highly dynamic production machine with a footprint of 46.28ft²

As the successor of the MILLTAP 700 (with more than 3,000 machines installed), the new DMP 70 stands for maximum productivity on the smallest space. With a footprint of just 46.28ft² it is 10 percent smaller than the MILLTAP 700.

DMG MORI has designed the compact production machine for applications in medical technology, job shops, as well as the aerospace sector and other demanding industries.

Travel paths of 27 x 16 x 15 inches and the optional integrated swivel/rotary table enable 5-axis simultaneous machining of a wide range of components making the DMP 70 the ideal addition to any shop floor. Automation solutions such as the workpiece handling WH 3 Cell which can be connected from the right, left, or front of the DMP 70, will be presented at Innovation Days.

5-axis Excellence: Complete machining for more productivity

5-axis machining was initially an answer to the trend towards increasingly complex work pieces. Today, it is increasingly becoming part of productive mass production in many industries, including aerospace, automotive, medical, and tool and mold making sectors. DMG MORI has been supporting these trend-setting industries with innovative manufacturing solutions for many years.

The machine tool manufacturer will be showing a representative cross-section of its wide-ranging 5-axis portfolio during the Innovation Days in Chicago. DMG MORI will present a DMU 50 3rd Generation automated with a PH 150 pallet handling, two monoBLOCK machines and two models from the duoBLOCK series as well as the DMU 200 Gantry. The ULTRASONIC 20 linear and the LASERTEC 3D machines for additive manufacturing complete the 5-axis exhibits.

The 5-axis technology has proven to be an efficient machining solution for complex workpieces. It can manufacture parts in one clamping when 3-axis milling requires at least two or more process steps. With its experience in 5-axis machining DMG MORI consults customers specifically regarding their applications. This Solutions Experience includes technological aspects as well as economic challenges.

Thus, customers are able to compare expected costs for machining complex parts using 5-axis or 3-axis machining. This work also involves looking at solutions for the financial investment into a 5-axis machining solution. During Innovation Days DMG MORI will have a special counter where experts will present the technological and economic advantages of 5-axis technology.

Automation Solutions: More value creation through integral automation solutions

Automated machines are crucial components of a digital factory and therefore an integral part of intelligent and networked production. DMG MORI views automation as a strategic future-oriented field. The production plant in Davis assumes an important role in the development and implementation of automation solutions. The portfolio ranges from technical consultations and budgeting, to possible machine modifications, and installation and commissioning.

The experts in Davis also assume other optimizations, the tooling and teaching of robots offering customers a complete automation solution from a single source. During Innovation Days DMG MORI will present, among others, automation solutions for machines produced locally in Davis. The CMX 1100 V will be equipped with versatile modular workpiece handling MATRIS and the ALX 2000 – a US premiere – will be shown with the GX 7 gantry loader.

Additionally, DMG MORI demonstrates the NHX 4000 with a RPS for 21 pallets and the NHX 6300 with a LPP for twelve pallets. Further examples of efficient automation solutions will be the flexible Robo2Go 2nd Generation for a wide variety of turning centers, the DMU 50 3rd Generation with a PH 150 Pallet handling, and the DMP 70 with WH 3 workpiece handling.

ADDITIVE MANUFACTURING: Bundled competence at the ADDITIVE MANUFACTURING Excellence Center

ADDITIVE MANUFACTURING has long proven its enormous potential and is expected to grow in a high double-digit range. DMG MORI has already been operating successfully on the market for ADDITIVE MANUFACTURING.

As a global full-liner with over 20 years of experience in the ADDITIVE MANUFACTURING of metal parts, DMG MORI represents the most important generative machining processes under one roof and ranks as a full-service provider in both the additive production of metallic components and metal cutting finishing.

DMG MORI has five ADDITIVE MANUFACTURING Excellence Centers (AMEC) worldwide. The DMG MORI experts at the AMEC in Chicago design and realize pioneering additive manufacturing solutions involving powder bed and powder nozzle methods.

With a share of 30 percent in the Indian software developer INTECH DMG MORI has gained access to the key software and technological expertise for generative production. As a pioneer in the field of 3D print in India, the company has specialized in ADDITIVE MANUFACTURING and the related software solutions – including the artificial intelligence in this field.

A first result of this collaboration is the new OPTOMET software, which INTECH offers for the LASERTEC SLM series from DMG MORI. It has self-adjusting and learning algorithms that calculate the required parameters of the SLM process in advance within minutes.

Technology Excellence: Experience and competence for leading industries

With over 50 years of experience in machine tool manufacturing and a consequent orientation towards the future of production, DMG MORI is known as a competent partner for many industries. In particular, the leading sectors – aerospace, automotive, die & mold, and medical – drive the development of manufacturing technologies.

For DMG MORI this has led to the establishment of DMG MORI Technology Excellence Centers all over the world focused on these demanding industries.

In these Technology Excellence Centers, the machine tool manufacturer offers customers far more than simply excellent high-tech machines and outstanding technological performance. The DMG MORI experts are involved in future projects of customers at an ever-earlier stage. This results in the development of optimum manufacturing processes and complete turnkey solutions.

DMQP: Perfectly coordinated peripherals and accessories from one source

As an integrated solution provider, DMG MORI, in combination with their technologically leading machine tools, has been offering high-tech peripherals and innovative accessories from selected suppliers for a long time. DMG MORI is now enhancing their activities and offering innovative complete solutions from one source under the label DMG MORI Qualified Products (DMQP).

Certified DMQP partners have to satisfy the most stringent requirements relating to innovative capacity, technological expertise and quality. Coordinated interfaces, securing connectivity, price maintenance and defined warranty conditions ensure ongoing productivity increases for the manufacturing solutions of DMG MORI customers.

www.dmgmori.com