www.magazine-industry-usa.com

24

'10

Written on Modified on

With EPLAN Pro Panel, EPLAN Platform goes 3D

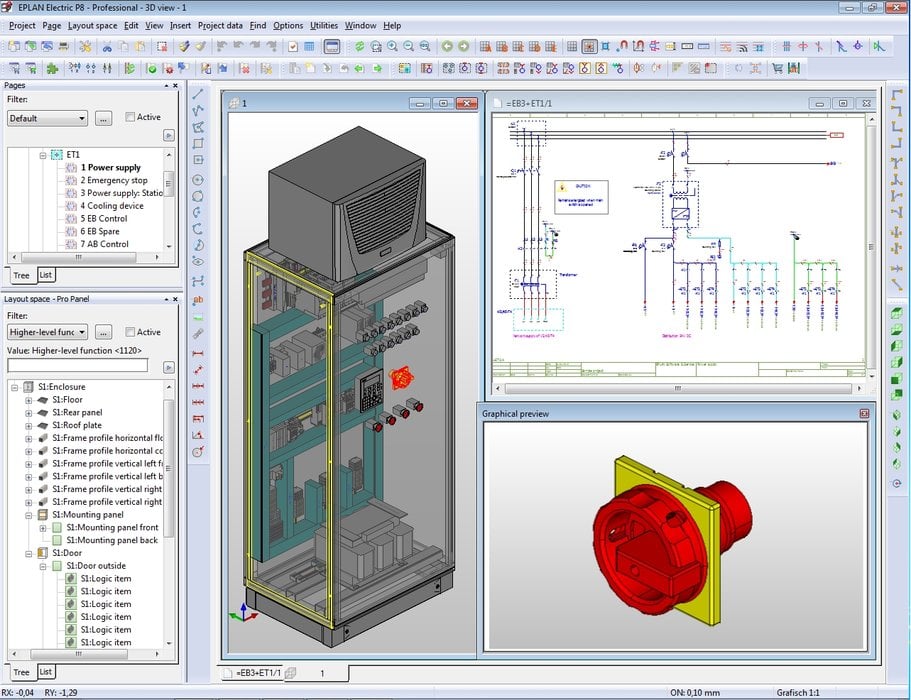

EPLAN Pro Panel offers specific 3D functionalities to define electrical and fluid engineering mounting layouts. The module starts with the brand-new 3D technology of the EPLAN Platform und facilitates a design process across various disciplines based on a common database. It provides uniform and consistent engineering with sustained data integrity.

EPLAN Pro Panel can be used to produce standardized mounting and production drawings quickly and easily with associative model views. It offers all necessary functions for populating mounting panels or defining power units and valve blocks, based on EPLAN Electric P8 or EPLAN Fluid. Online access to all the devices in the design, the EPLAN parts management, and the EPLAN Data Portal is included. The project design approach can be chosen freely. For example, the mounting layout can be planned flexibly even before a schematic exists. The user can, if necessary, start with populating a mounting panel and design the schematic afterwards. That means more than just a little more flexibility in the process. EPLAN Pro Panel constitutes a milestone in the process of parallelization of the product development process in electrical and fluid power design.

Completely integrated into the EPLAN Platform it also shows correct views of hidden edges. Mounting panels or power units and valve terminals can be equipped and assembled at the same time users create the schematic in EPLAN Electric P8 or EPLAN Fluid. The 3D mounting structure can be planned even before the schematic has been created. There is flexibility in the process, and in conjunction with the EPLAN Multi-User concept, it has become a milestone on the path to parallel running product development processes in electrical and fluid design.

EPLAN Pro Panel is designed to operate within manufacturer specifications and facilitates an exact position check of devices, wire ducts and mounting rails. EPLAN Pro Panel, and its dynamic collision control function is the perfect complement to the easy 3D component placing and editing operations. This is an indispensible application when the available mounting space must be used efficiently and mounting panel or enclosure layout is to be optimized. This is also beneficial to production, since exact length dimensioning leads to an exact fit down to the finest detail. The new-found design precision flows into other areas as well. The realistic depiction of 3D mounting construction not only makes communication with all relevant departments much easier, but also facilitates smooth coordination with the customer.

EPLAN Pro Panel shows all devices used in the schematic or in the parts pre-selection during the design of the mounting layout in a list or tree structure. When placing elements, the system verifies whether the placement is on the correct mounting panel -- especially since it can indicate immediately which devices from the schematic have yet to be placed on the mounting panel. First off, the user will determine if the 3D mounting layout will be done as the specified setting, or if the mounting panel will be populated according to the pre-settings from the electrical schematics. Placement of the components is absolutely easy to do, as each component has defined handles or mounting surfaces

Another distinct practical advantage: EPLAN Pro Panel supports the known basic engineering concepts and mechanisms of the EPLAN Platform. This may be for instance a macro function, use of options technology, the various revision management processes, or high-performance PDM interface. The new module distinguishes itself with deep integration and adaptation of tried and tested EPLAN technologies. Online access to all the devices in the design, the EPLAN parts management, and the EPLAN data portal are included. One data base, one interface, one user guide – this is 3D mounting layout with assurance of productivity.

Pictures:

propanel1.jpg: EPLAN Pro Panel facilitates quick and easy 3D design of electrical and fluid engineering mounting structures.

propanel2.jpg: Mounting panels can be populated or power units and valve terminals can be assembled at the same time you create the schematic in EPLAN Pro Panel.

Completely integrated into the EPLAN Platform it also shows correct views of hidden edges. Mounting panels or power units and valve terminals can be equipped and assembled at the same time users create the schematic in EPLAN Electric P8 or EPLAN Fluid. The 3D mounting structure can be planned even before the schematic has been created. There is flexibility in the process, and in conjunction with the EPLAN Multi-User concept, it has become a milestone on the path to parallel running product development processes in electrical and fluid design.

EPLAN Pro Panel is designed to operate within manufacturer specifications and facilitates an exact position check of devices, wire ducts and mounting rails. EPLAN Pro Panel, and its dynamic collision control function is the perfect complement to the easy 3D component placing and editing operations. This is an indispensible application when the available mounting space must be used efficiently and mounting panel or enclosure layout is to be optimized. This is also beneficial to production, since exact length dimensioning leads to an exact fit down to the finest detail. The new-found design precision flows into other areas as well. The realistic depiction of 3D mounting construction not only makes communication with all relevant departments much easier, but also facilitates smooth coordination with the customer.

EPLAN Pro Panel shows all devices used in the schematic or in the parts pre-selection during the design of the mounting layout in a list or tree structure. When placing elements, the system verifies whether the placement is on the correct mounting panel -- especially since it can indicate immediately which devices from the schematic have yet to be placed on the mounting panel. First off, the user will determine if the 3D mounting layout will be done as the specified setting, or if the mounting panel will be populated according to the pre-settings from the electrical schematics. Placement of the components is absolutely easy to do, as each component has defined handles or mounting surfaces

Another distinct practical advantage: EPLAN Pro Panel supports the known basic engineering concepts and mechanisms of the EPLAN Platform. This may be for instance a macro function, use of options technology, the various revision management processes, or high-performance PDM interface. The new module distinguishes itself with deep integration and adaptation of tried and tested EPLAN technologies. Online access to all the devices in the design, the EPLAN parts management, and the EPLAN data portal are included. One data base, one interface, one user guide – this is 3D mounting layout with assurance of productivity.

Pictures:

propanel1.jpg: EPLAN Pro Panel facilitates quick and easy 3D design of electrical and fluid engineering mounting structures.

propanel2.jpg: Mounting panels can be populated or power units and valve terminals can be assembled at the same time you create the schematic in EPLAN Pro Panel.