www.magazine-industry-usa.com

11

'18

Written on Modified on

Eaton expands prefabricated electrical assembly program, helping contractors achieve dramatic productivity gains in commercial construction projects

Eaton builds on its digital tools making it easier and faster to configure custom branch circuit assemblies and work with electrical contractors

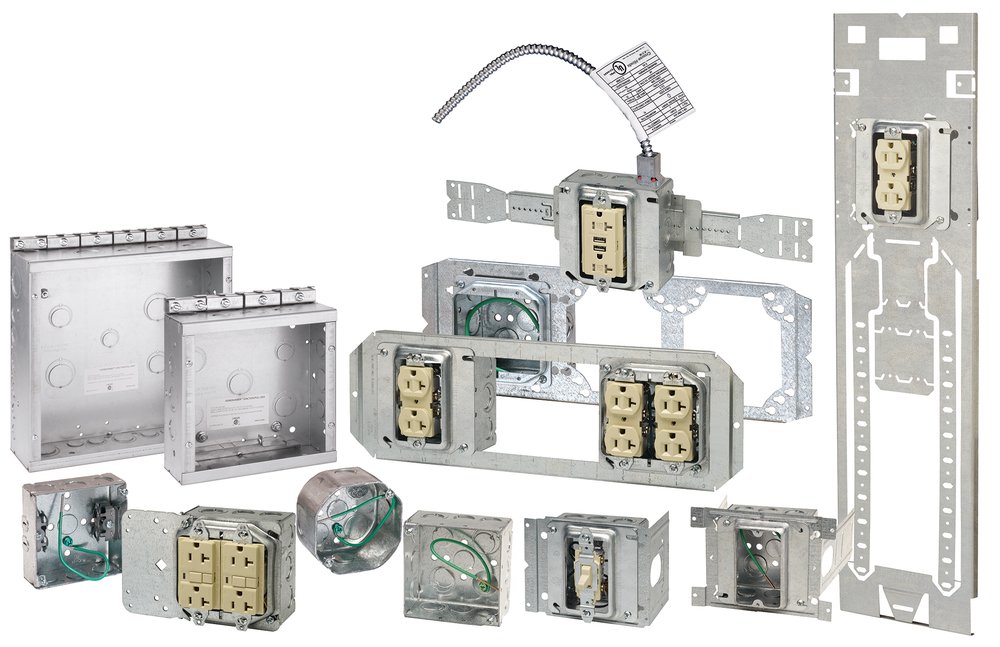

Eaton’s range of prefabricated solutions for branch wiring, from a complete engineered to a custom-configured solution, help electrical contractors drastically improve productivity, reduce material handling time and optimize labor on their projects.

Industry experts estimate that prefabrication can increase worker productivity from 20-30 percent through reductions in material handling on the job site and rough-in time. With the current shortage of skilled labor, pre-built products can also help close the capacity gap.

“Eaton has a long history of delivering prefabricated and modular products that save costs and installation time for contractors, helping them complete projects on schedule” said Michael McManus, global product line manager, commercial products at Eaton.

“Our recent investments are shortening lead times, making it easier to configure assemblies and providing added support for electrical contractors.”

Eaton is increasing its production capacity for PRE-formance products with a second production line at its manufacturing facility in Texas. This additional manufacturing location will supplement the existing production center located in Pennsylvania and provide faster lead times for assemblies in the West and Gulf regions.

Eaton is also adding more customer support for PRE-formance assemblies with the addition of Scott Pingree as a second project manager. Pingree, a licensed electrician, has over two decades of experience working as a project manager and estimator in the Pittsburgh area.

Additionally, Crouse-Hinds series PRE-formance assemblies can now be configured using the Eaton BidManager tool available to electrical contractors on Eaton.com, which will reduce the time and complexity of product selection and pricing.

This configuration tool enables electrical contractors to configure custom branch circuit assemblies and request a quote through their local Eaton distributor. These advanced selection capabilities can drive further reductions in material management time, helping electrical contractors deliver projects on schedule.

Eaton’s electrical business is a global leader with expertise in power distribution and circuit protection; backup power protection; control and automation; lighting and security; structural solutions and wiring devices; solutions for harsh and hazardous environments; and engineering services.

Eaton is positioned through its global solutions to answer today’s most critical electrical power management challenges.

Eaton is a power management company with 2017 sales of $20.4 billion. We provide energy-efficient solutions that help our customers effectively manage electrical, hydraulic and mechanical power more efficiently, safely and sustainably.

Eaton is dedicated to improving the quality of life and the environment through the use of power management technologies and services. Eaton has approximately 98,000 employees and sells products to customers in more than 175 countries. For more information, visit Eaton.com.

www.eaton.com/us