www.magazine-industry-usa.com

15

'18

Written on Modified on

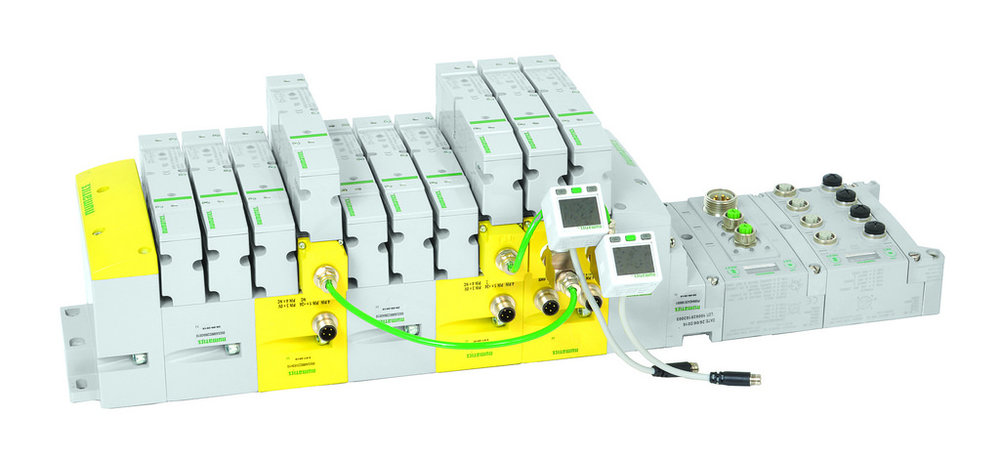

ASCO Introduces Zoned Safety Capabilities in Numatics 503 Series Valve Manifold

“With this functionality, the original equipment manufacturer (OEM) and end user can easily and cost-effectively configure up to three safety circuits in a production machine using a single Numatics 503 Series valve manifold with G3 fieldbus electronics,” said Robert W. Kemple, Jr., executive vice president, sales and marketing – Americas, ASCO. “Our simple, user-friendly zoned safety approach reduces components, saves space, plus improves design flexibility.”

The zoned safety concept is an integrated approach to machine safety and control that greatly simplifies the design of a redundant pneumatic safety circuit with a manifold system. The Numatics 503 Series can create up to three independent electro-pneumatic safety zones, while also allowing independent non-safe sections to co-exist within one manifold assembly. The operator does not have to shut down the entire machine by releasing compressed air with a redundant safety/control dump valve. Instead, the Numatics 503 Series valve manifold can be configured to shut down air and power only to the group of valves that controls the machine’s motion in the operator’s vicinity.

“Because zoned safety capability is designed into the standard Numatics 503 Series valve manifold platform, no redesign is required and the user has optimal choices when selecting valve options, accessories, and flow requirements,” said Kemple. “The flexible approach also significantly reduces safety system cost and allows valuable machine space to be saved for other purposes.”

www.asco.com.