www.magazine-industry-usa.com

22

'18

Written on Modified on

CityAirbus – Siemens presents Drive System for Air Taxi

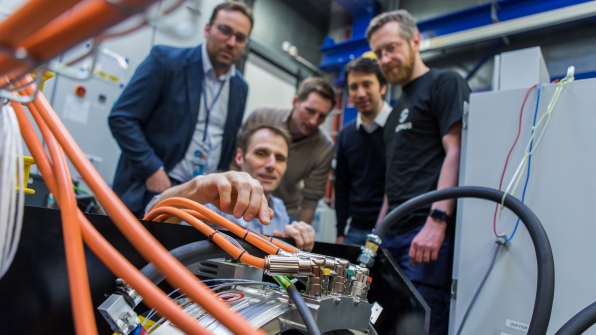

Since 2016 Airbus and Siemens have been working together on the development of hybrid-electric propulsion systems for the aviation sector. One of the pioneering aircraft incorporating these technologies is the CityAirbus; a disruptive demonstrator designed to the particular needs of urban air mobility. On the path to its maiden flight, which is scheduled for late this year, the aircraft has now reached an important milestone: The ground tests have started.

Mr. Nüsseler, Dr. Anton, what exactly is this object in front of us?

Nüsseler: We are in front of the CityAirbus “iron bird”. The CityAirbus is an electric multi-copter aircraft concept for urban mobility. We are using the iron bird to test the entire propulsion system end-to-end. It includes the batteries, power distribution system and electric propulsion units to be operated in a closed control loop via the Autonomous Flight Control System. On this full system test rig, we are operating and verifying the entire system dynamic, including electric, thermal and mechanical aspects. The Siemens electric drive units are part of this set-up and connected to electric load machines emulating the real propeller loads. This is an important milestone on the path to the first flight, which is scheduled for late this year.

Anton: The eight motors that you see here are electric drive systems with a maximum power of 200 kW each that have been specially designed for this specific application. They have a torque density of 30 Nm/kg, which is practically a new record. In other words, we are generating a nominal torque of about 1,500 Nm with a weight of less than 50 kg. In addition to the motors, we are also supplying the inverters and the energy management system. Incidentally, we were able to deliver this drive system in an extremely short period of time. It took us just over nine months to develop it from the initial concept to the finished prototype. That’s certainly thanks to our strongly committed team, as well as the digital tools, especially SimcenterTM from PLM, that we generally use for development work at eAircraft.

Can you tell us a little bit more about the CityAirbus and its areas of application? Also, how significant is this project for the future of electric flight?

Nüsseler: The battery-powered CityAirbus is an urban air mobility concept to transport up to four passengers safe and quickly on low operation costs and without local emissions way across congested megacities with a speed of up to 120 km/h. Typical destinations are airports, train stations or skyscraper roofs. It will initially fly with a pilot on board, but also an aircraft flying autonomously is in planning.

Anton: The innovative configuration of four ducted propeller drives contributes significantly to the system’s safety and ensures a low noise level. The idea of moving traffic into the “third dimension” — that is, into the air — can in any case benefit from the fact that electric motors are much quieter and generate far lower emissions than conventional engines. However, these are only a few of the advantages of electric mobility that this application takes full advantage of. The CityAirbus will have to take off and land vertically and be able to maneuver in all directions, and it also has no wings for gliding. This means that its uplift must be generated by the drive system alone. Its drive system, which consists of electric motors with a high torque, is the ideal solution for that.

When can I fly in it? And what are the next steps on the way to the maiden flight?

Bebesel: We’re planning to physically integrate the propulsion system into the demonstrator in the middle of this year. The initial structures of the CityAirbus have already been produced and are now being assembled. For a serial aircraft the configuration will be further optimized to the requirements of urban missions and increase profitability in business case. A commercial product could be technically realized by 2025 but is depending on the progress of public acceptance, infrastructure and regulations established for such urban air traffic.

Anton: Through our work on this project we are demonstrating the technical feasibility of the plan to supplement urban mobility with electric aviation. We hope that the tests on our flying demonstrator can support our application for type certification and also that they will spark public enthusiasm for this concept.

www.siemens.com