Integration: Eplan and Melsoft iQ Works

AutomationML makes it possible! The new integration solution from Eplan Electric P8 to Melsoft iQ Works by Mitsubishi Electric connects electrical engineering to automation. Data such as symbolic addresses, for instance, can now be exchanged bi-directionally with the current software suite. The results in Eplan Electric P8 are impressive: valid schematics, including bus wiring for PLC components amongst themselves, and top quality hardware configurations.

Bi-directional exchange of PLC data helps optimize processes in engineering and automation. With the new integration between Eplan Electric P8 and Melsoft iQ Works, solutions provider Eplan and Mitsubishi Electric have taken this a step further. AutomationML forms the integration´s foundation, which paves the way towards Industry 4.0 with its neutrality and openness for data exchange. The dataset created in Eplan forms the basis for PLC hardware (rack) assembly and software programming. What makes it special is the data are transmitted along the whole product development process as a single source of truth. Eplan Data Portal provides the necessary component data. Working together, they accelerate component configuration and design planning.

Melsoft iQ Works is an integrated software suite and includes the software solutions required to program Mitsubishi Electric automation products. With the new integration to the current Eplan Platform, Version 2.7, users can exchange, later edit, and synchronize project data in any direction at all stages of the project. Users no longer have to enter data more than once, thus helping avoid entry errors. It also makes cooperation between electrical design engineers and software developers easier. Users in electrical design even have additional benefits: the allocation of PLC assemblies is transparent. Assemblies can be more quickly edited with system support, and last minute changes are easier and more universally implementable.

AutomationML Technology

As a non-proprietary, standardized and XML-based data format, AutomationML can depict design information with respect to system topologies and structures, geometries and logic. To display the structural and topology information, AutomationML uses the CAEX (Computer Aided Engineering Exchange) format, an international data format standard according to IEC 62424/IEC 62714. It offers fundamental object-oriented concepts that can be used to represent plant and system structures. AutomationML additionally offers the possibility for transmitting system structures, for instance the rack assembly. This allows for well-structured, end-to-end documentation, even for servicing and maintenance. Finally, data from various software tools, for example device information, can be exchanged between manufacturers and users and easily integrated into the documentation.

About iQ Works

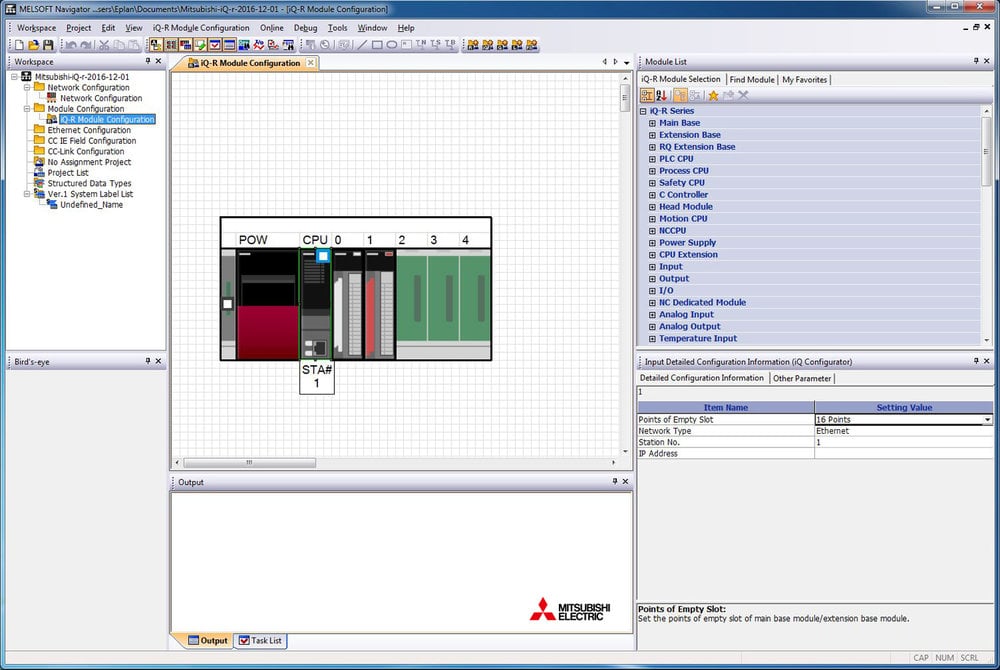

Melsoft iQ Works is an embedded software suite that consolidates the programs needed to program automation products from Mitsubishi Electric - GX Works3, MT Works2, GT Works3, RT ToolBox2 and FR Configurator2. The software integration is supported through the Navigator, a graphical, easy-to-use interface between the user and central system configuration. Another simplification is achieved through the project spanning use of system labels and parameters. The benefits of this powerful software suite include simplified system development thanks to it requiring considerably less effort for repetitive tasks, minimizing sources of errors, and lowering overall operating costs associated with such errors.

Background

Eplan and Mitsubishi Electric have been working together in a strategic partnership for years. Solutions provider Eplan is a member of the e-F@ctory Alliance; conversely, Mitsubishi Electric provides its data in Eplan Data Portal. The goal for both companies is clear with respect to their customers/users: increase data quality, accelerate engineering and manufacturing processes and boost productivity.