www.magazine-industry-usa.com

30

'17

Written on Modified on

New 10-year supplier agreement with Maersk Container Industry

After several months of negotiations Danfoss Drives has signed a 10-year supplier agreement with Maersk Container Industry (MCI) to provide the drives for their next generation Star Cool Reefers.

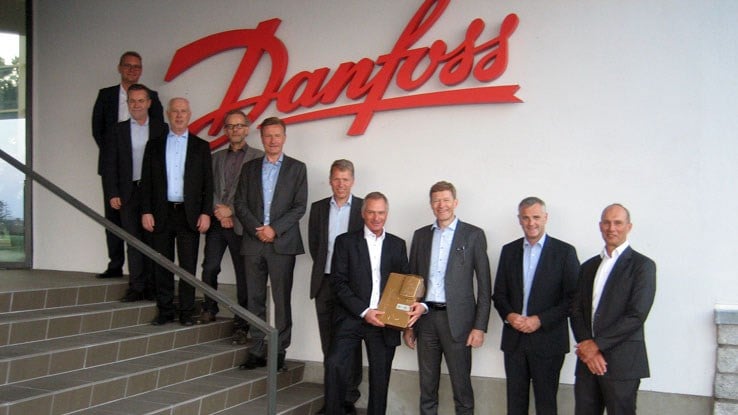

The first production sample of the CPE133 (P3000) was presented to Stig Hoffmeyer by Niels Bjørn Christiansen.

The primary focus in the development of the CPE133 was increased robustness against the very harsh environments the container freight market experiences in terms of, for example, temperature variations, humidity, salt and vibrations.

New design processes involving simulation of stress from vibration and new motor control elements were adopted to guarantee the highest efficiency and ensure the maximum lifetime of all components. The result is a frequency converter which has already proven its strength during a 12-month field-test period under the worst conditions, without a single breakdown.

Simulation of mechanical stress resulting from vibrations.

“Our ability to understand the customer’s business and their specific needs and transform this knowledge into a product really made the difference. The performance level we demonstrated convinced MCI that they should choose Danfoss as a supplier of drives for their next generation Star Cool Reefers FC2.0, which resulted in their commitment to a long-term supplier agreement,” explains Stefan Desch.

Stig Hoffmeyer shaking hands with Vesa Laisi.

Stig Hoffmeyer signing the contract with Ian Barrie.

The need for the highest quality in production has also been addressed by the Danfoss team in the Haiyan/China factory. Intelligent screwdrivers to ensure assembly quality, and RFID systems to control and track the drive have been implemented as new technologies on the manufacturing line.

“We have been able to demonstrate to MCI that, with the new product, we will be able to fulfill their demands for reliability in challenging environments, and provide a future-proof, energy-efficient, customized solution,” explains Mr Desch.