www.magazine-industry-usa.com

07

'25

Written on Modified on

ABB invests in strategic partnership with US start-up Molg

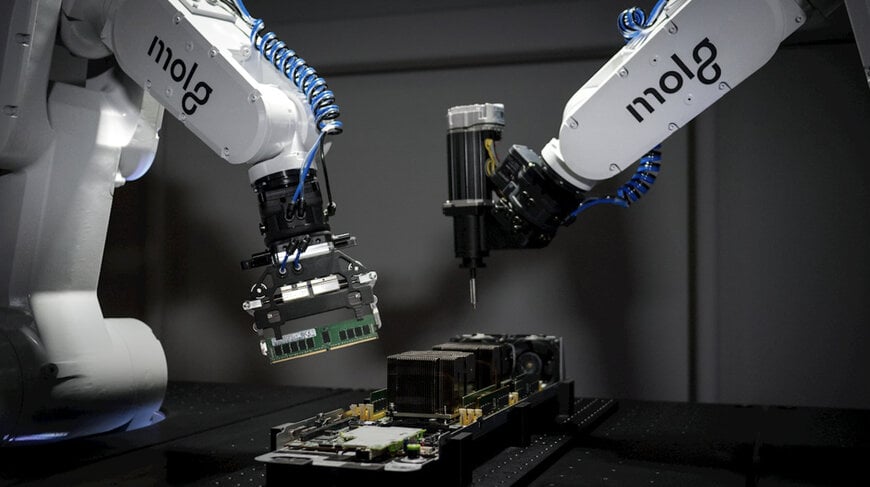

Companies will develop design architecture for drive manufacturing by optimizing testing and assembly processes in Molg’s robotic Microfactories.

global.abb

ABB Motion’s Drive Products division has invested, through ABB Motion Ventures, in Virginia-based circular manufacturing company Molg to optimize manufacturing design and reusability of ABB drives. The collaboration will leverage Molg’s design expertise and US-based robotic Microfactories to streamline the assembly and testing processes within ABB’s manufacturing operations, while simultaneously increasing drives’ circularity and resource efficiency.

ABB and Molg’s relationship began in 2023 when the company was recognized as a winner of the ABB Accelerating Circularity Startup Challenge. ABB Drive Products and Molg have subsequently delivered a successful proof of concept in drives assembly in robotics-based Molg Microfactories and this fresh investment will enable the next phase of their partnership.

A central aspect of ABB Drive Products’ choice to invest in Molg is the firm’s circularity credentials. ABB is committed to achieving a full life cycle circular approach for 80 percent of its products by 2030 and Molg’s robotic Microfactories will help to improve the efficiency of manufacturing configured-to-order drives by streamlining the assembly and testing processes with automation. The investment strengthens ABB’s position as a key enabler of circular economy by re-using, re-purposing, and recycling components. ABB Robotics & Automation Ventures participated in Molg’s seed round of funding in October 2024 to help scale the start-up’s production capacity and tackle e-waste with robotics and design.

This strategic partnership follows ABB’s recent $100 million campus project in New Berlin, Wisconsin, and further enables its ‘local for local’ strategy – using locally-sourced materials for in-country manufacturing to service local customers. This is also a vital part of ABB’s circularity-based approach, not only minimizing waste and manufacturing-related carbon emissions, but providing crucial in-market support for companies across the supply chain.

new.abb.com