www.magazine-industry-usa.com

22

'25

Written on Modified on

Eliminate Costly Defects with Smart Meaurement Sensors

Contrinex Smart Sensors, designed with the needs of OEMs and system integrators in mind, have all the answers when it comes to reducing complexity and cost.

www.us.contrinex.com

In high-stakes assembly lines, where precision is everything, missing weld nuts can spell disaster—causing expensive reworks, downtime, and scrap. Contrinex’s cutting-edge DMS Inductive Smart Measurement Sensors, paired with the innovative PocketCodr configurator, are transforming how manufacturers detect and prevent these costly errors.

The Challenge: Hidden Defects, Skyrocketing Costs

Weld nuts are vital components used to create strong, threaded mounting points in thin sheet-metal parts, especially in automotive and white goods manufacturing. A missing weld nut renders a product useless but often goes unnoticed without robust detection systems, leading to downstream production chaos.

Manufacturers need a reliable solution that detects these defects in real time and can adapt to diverse panel designs—without requiring specialized programming expertise.

The Solution: Smart Sensing with PocketCodr Precision

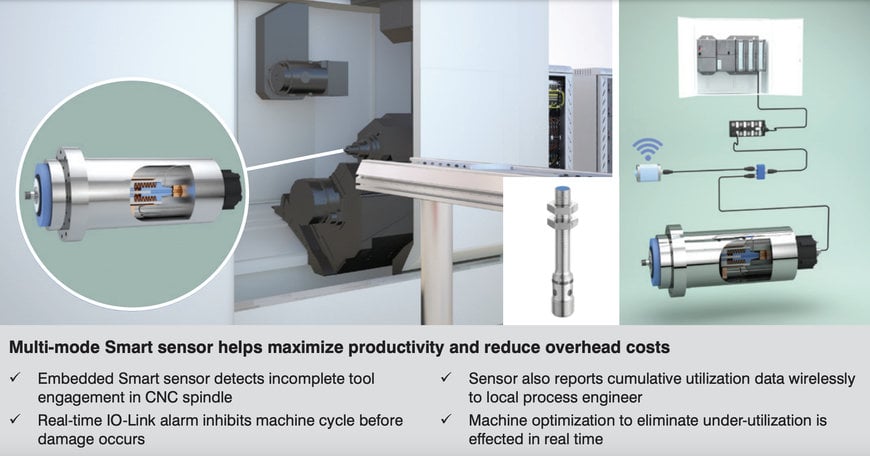

Contrinex’s DMS Inductive Smart Measurement Sensors rise to the occasion, delivering real-time, no-contact detection with unmatched accuracy. These sensors, embedded in robust M12 metal housings, are designed to identify missing weld nuts with precision, even in challenging environments.

Paired with the PocketCodr handheld configurator, technicians can configure sensors for varying panel sizes and geometries quickly and effortlessly. No coding skills? No problem. The PocketCodr app offers an intuitive interface, enabling seamless setup and monitoring via a smartphone or mobile device.

Here’s how it works:

- Sensors confirm the presence or absence of weld nuts at pre-set positions on robotically loaded panels.

- Detected defects automatically trigger the rejection of faulty units, eliminating defective parts from the production line.

- Built-in delay and timer functions prevent false positives, ensuring good parts are not mistakenly discarded.

Benefits for Manufacturers

The combination of DMS Smart Measurement Sensors and PocketCodr delivers a host of advantages:

- Early Defect Detection: Stop incomplete assemblies in their tracks before they cause disruptions.

- Plug-and-Play Replacement: Sensors store their configurations locally, enabling hassle-free swaps with no recalibration.

- Simplified Setup: The no-code PocketCodr configurator slashes setup time, cutting costs and minimizing downtime.

- Seamless Integration: Industry-standard IO-Link connectivity ensures smooth integration with existing control systems.

- Durability Under Pressure: Built with stainless-steel housings, these sensors excel in harsh environments.

A Smarter Future for Manufacturing

By investing in Contrinex DMS Inductive Smart Measurement Sensors, manufacturers gain a reliable, repeatable system that eliminates defects, boosts efficiency, and protects profits. Whether you're in the automotive sector or white goods production, this groundbreaking solution ensures every product rolling off the line meets exacting quality standards.

By investing in Contrinex DMS Inductive Smart Measurement Sensors, manufacturers gain a reliable, repeatable system that eliminates defects, boosts efficiency, and protects profits. Whether you're in the automotive sector or white goods production, this groundbreaking solution ensures every product rolling off the line meets exacting quality standards.

Explore our full range of Inductive Smart Measurement Sensors here.

Get all the details—download our Smart Sensor flyer here.

www.contrinex.com