Redex Preloaded Systems Deliver Precise Positioning for Machine Tools

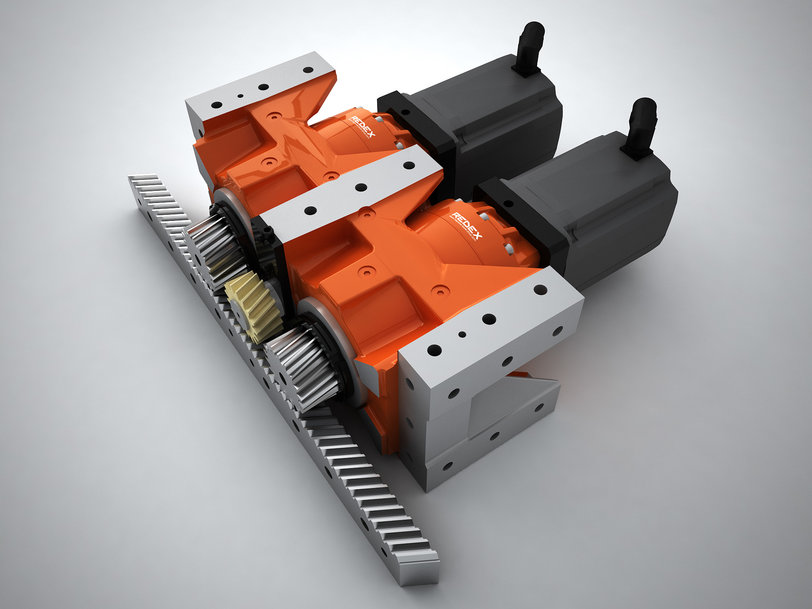

Redex is pleased to announce its patented DualDRIVE and TwinDRIVE preloading technologies now give CNC machine designers several ways to build a zero backlash system.

redexusa.com

These approaches leverage Redex modular SRP, DRP, KRP and KRPX Series rack and pinion reducers whose output pinions are preloaded against the rack to eliminate backlash — a longstanding challenge with designs that require long axis travels and require positioning over the entire length of travel to less than 0.001 inch.

Here’s how DualDRIVE and TwinDRIVE preloading technologies work to create a zero-backlash system:

- Redex Patented DualDRIVE. These systems achieve a mechanical preload by torsionally winding one pinion against the other when both pinions are in contact with the same rack. DualDRIVE needs just one motor, and no special controllers are required.

- TwinDRIVE. Twin Drive technology electrically brakes one pinion against the other — driving — pinion when both pinions are in contact with the same rack. These systems incorporate two motors and gearboxes for use with CNC control.

Redex SRP, DRP, KRP and KRPX Series rack and pinion reducers, together with DualDRIVE or TwinDRIVE technology, let machine designers create zero-backlash preloaded systems that achieve precise positioning and improved stiffness in CNC applications. These reducers feature optimized radial and torsional stiffness, very high linear accuracy, compact sizes and precision geometry for meshing with the rack. They can be implemented in the following ways:

DualDRIVE

- Two Right Angle SRP planetary reducers (SRP DualDRIVE Kit)

- Two Right Angle KRP planetary reducers (KRP DualDRIVE Kit)

- One Right Angle DRP including two planetary reducers in one housing (DualDRIVE)

TwinDRIVE

- Two SRP planetary reducers (SRP TwinDRIVE Kit)

- Two KRP planetary reducers which is called (KRP TwinDRIVE Kit)

- One DRP including two planetary reducers in one housing (TwinDRIVE)