www.magazine-industry-usa.com

27

'23

Written on Modified on

SIKO supports development project for autonomously operating harvesting vehicle in fruit orchards

Besides Industrial applications, SIKO GmbH is also supporting an agricultural research and development project with two rotary encoders from its range for mobile machines.

“AurOrA” (Autonomous Orchard Assistant Altes Land) is a small autonomous vehicle which in future will move independently around fruit orchards and detect full fruit boxes, pick them up and take them to a defined unloading point. The robot eases the burden on harvest workers and allows them to concentrate on more challenging tasks. Technology and automation should increasingly help to avoid monotonous, tiring activities and is set to make the job of fruit growers significantly easier. The idea for the project comes from practice: fruit farmer Johann Schröder from Jork in the “Altes Land” region south-west of Hamburg asked hochschule 21 in Buxtehude for help in developing an autonomously operating vehicle of this sort. The project was launched in collaboration with the agricultural equipment manufacturer PWH from Jork in February 2020. The demand for technical support is high among fruit orchard owners and the project is therefore intended to turn into a market-ready, profitable product in the medium term. The concrete objective of the project, however, is to deliver a functioning prototype by January 2023 in the first instance, which will demonstrate its practical feasibility. The project is funded through the ZIM funding program of the Federal Ministry for Economics.

Second milestone: robot drives autonomously

The project is currently in the last third of the planning stage, having achieved its second milestone: the robot can already operate largely autonomously in an orchard. Work is still being carried out on avoiding collisions and detecting the ground conditions, to avoid getting the wheels stuck in muddy ground, for example, or drifting off course into a ditch. Milestone number three will then be actually to pick up a box and transport it.

A development project of this sort always poses particular challenges, starting with coordination of the interests of various fruit farms, which often have very different harvesting processes, through problems with the infrastructure, such as a stable cell phone standard so that the robot can receive GPS data and communicate with the operator, to practical difficulties in day-to-day outdoor operation (weather conditions, snow, rain, sunshine, ground conditions).

SIKO supports future-oriented projects

Sensors that carry out various measuring tasks are needed for a vehicle that operates autonomously. Measurement and sensor specialist SIKO was called in to work on the steering angle detection and positioning of the box holders. With many years of experience in mobile machines and agricultural machine technology, SIKO was able to contribute its expertise to the planning phase and ultimately came up with two suitable rotary encoder types that support these important functions. Alexander Kammann, research assistant at hochschule 21, appreciates the work of the SIKO experts: “We were pleasantly surprised by the willingness of SIKO to support future-oriented projects and how committed they were in offering their advice. In the beginning, we were not even sure what requirements we actually had of the sensors. We worked all this out and defined it together.”

Robust rotary encoder for tough environmental conditions

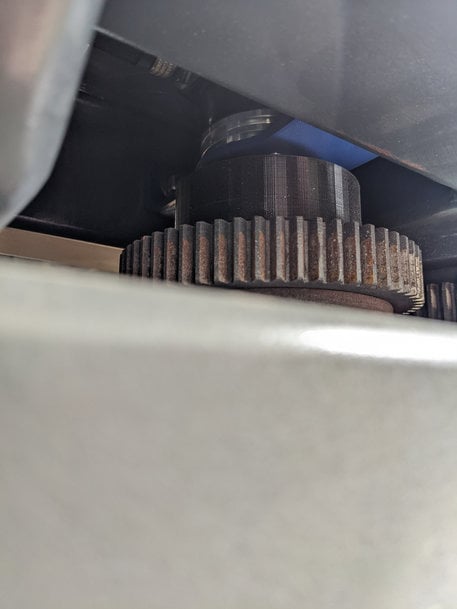

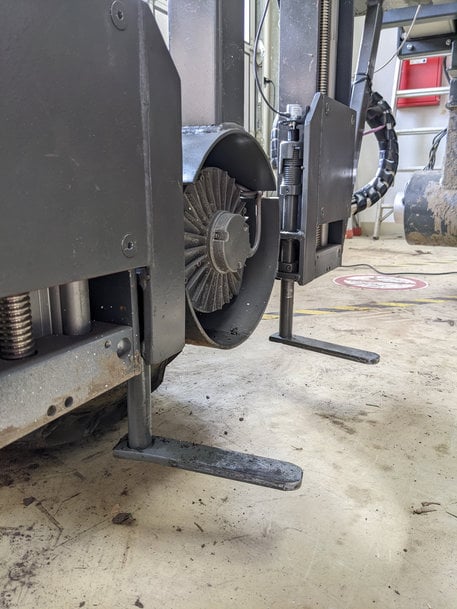

First of all, potential sensors must be extremely robust and resilient in the face of tough outdoor conditions (mud, dust, rain, strong sunshine, unevenness in the ground). Components in the PURE.MOBILE range of sensor modules from SIKO are particularly suitable for use in mobile machines under harsh environmental conditions. A double wheel is fitted to the back of the vehicle, which can rotate and thus control the steering. The steering angle is recorded, processed and sent to the controller by the WV5800M magnetic rotary encoder. This is a multiturn rotary encoder by means of which even multiple rotations can be detected absolutely. If the power supply is interrupted, because the batteries are flat for example, the steering angle previously set is still present. Without an absolute encoder, this would incorrectly be set as the zero degrees angle when the vehicle is started up again. The magnetic measurement principle meets the requirements of robustness and resilience. The high precision and reliability of the rotary encoder also impressed the team, meaning that the vehicle always adjusts its steering angle so that it keeps to its defined path – without failures or unacceptable deviation from tolerances. In order to increase safety in interaction with the people working in the orchard still further, the WV58MR safety variant of the rotary encoder with redundant position detection will be used for future vehicles to reliably prevent failures. In the development phase, the focus was initially on technical feasibility, so that the rotary encoder without the safety standard was adequate. The plus point of the SIKO models: the two rotary encoders are identical in design, so that no mechanical adjustments need to be made to the application when swapping them. A CANopen interface was also required for the steering angle detection system so that as many standard electronic components as possible can be used, replaced quickly and integrated into the system bus.

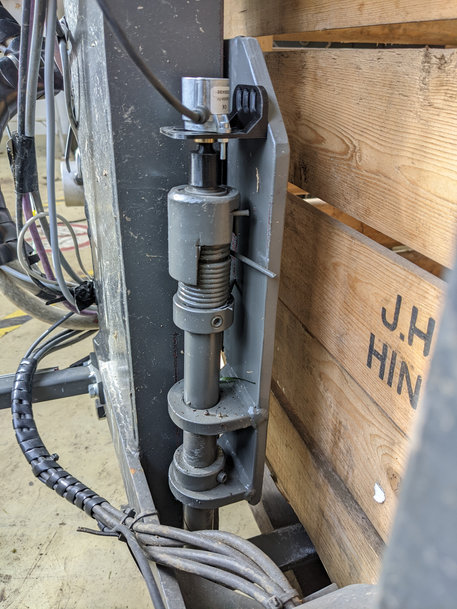

Position sensors for the “flippers”

The second SIKO rotary encoder, the AH25S, is even smaller and more compact, but no less robust. It is a single turn rotary encoder which monitors the position of the box holders, the so-called flippers. The filled fruit box is picked up at four points by one flipper for each. When the robot moves over the box and the spring-loaded holders touch it, the flippers swivel to the side, then open automatically and are then located under the four corners of the box for pick-up. In order to be able to transport the box safely, the position of each flipper must be known: has it really swiveled back or has it jammed? Are all four flippers under the box to ensure that it is picked up correctly? The space is very restricted, so a miniature rotary encoder was required which could be used directly without a special holder. An analog encoder is adequate here, as the data is less critical than that provided by the steering angle sensor.

A harvesting tool with real added value

Many little cogs have to interlock in a development project of this sort to turn a vague idea into a technically perfect product, which in future can be used with a balanced cost-benefit ratio in numerous orchards. In order to offer farms genuine added value, the intention is to use “AurOrA” for other maintenance work, too, such as mulching and mowing or as support for planting new trees. Effective use virtually throughout the year is therefore possible and is not just restricted to harvest time.

Images:

Image 0) The autonomously operating, intelligent harvest assistant “AurOrA”. Image: ©hochschule 21

Image 1) The “AurOrA” harvest assistant will navigate through the rows of trees in an apple orchard and detect and pick up fruit boxes and transport them to a defined unloading point autonomously in future. Image: ©hochschule 21

Image 2) and 3) Important details of the steering: The WV5800M multiturn rotary encoder records the steering angle so that the vehicle can follow its defined path reliably. Image: ©hochschule 21

Image 4) and 5) The position of the box holders, the so-called flippers, is detected by the robust AH25S miniature rotary encoder (the rotary encoder is located at the top of the structure). Image: © hochschule 21

Image 6) The AH25S, WV5800M and WV58MR encoders described in the article. Image: ©SIKO GmbH

Image 7) Alexander Kammann MSc., research assistant at hochschule 21. Image: ©hochschule 21