CASE STUDY - FEGA & SCHMITT

FEGA & Schmitt cut cost by 75% with smart roll cages from Wanzl and BOX ID Systems connected to Heliot’s 0G Network.

Challenge

FEGA & Schmitt recognised the opportunity to improve efficiency, reliability, and asset utilisation when transporting electrical goods in roll cages from a central warehouse to distribution centres for customer delivery.

Solution

Partnering with smart systems providers Wanzl and BoxID, FEGA & Schmitt deployed smart roll cages connected to the Heliot Europe 0G Network. The IoT solution enables remote tracking of cages for improved efficiencies and a better customer experience.

Results

Smart roll cages provide visibility and data insights enabling optimisation of operational processes:

- improved transportation efficiency

- reduced losses and damages

- optimised asset utilisation

- reduced cost, time and space

Good reasons for FEGA & Schmitt to digitise its fleet

For nearly 50 years, FEGA & Schmitt has supported the German electrical industry by distributing high-quality goods, reliable services, and excellent customer service.

Traditionally, FEGA & Schmitt transported goods across its distribution network on wooden Euro pallets and shrink wrapping the bundle. Freight forwarders shipped the pallets to regional distribution centres, where transporters took over to manage the final delivery to customers.

As the pace of business accelerated over the years, this process became slow, expensive, and error-prone.

Pallets were vulnerable to theft, loss, and damage. The process lacked transparency to let FEGA & Schmitt pinpoint problems impacting the end-user experience. Common challenges included slow pallet return to FEGA & Schmitt for re-use, incorrect delivery, and lack of pallets available in the right place at the right time for reliable distribution.

FEGA & Schmitt chose the 0G Network because of its ability to reliably support two-way communication over long distances across outdoors and indoors environments. It provides FEGA & Schmitt with instant, easy network connectivity and European coverage.

The BOX ID device is a cost-effective all-in-one solution that remotely monitors and sends near real-time location information on roll cages to a web-based application. Every pre-configured device uses long-life batteries, performing maintenance free over many years. Connecting the roll cage to the Heliot Europe 0G Network is seamless and easy. The solution integrates data from other tracking technologies, including QR codes, barcodes, and RFID tags, to give FEGA & Schmitt a comprehensive view of its distribution network.

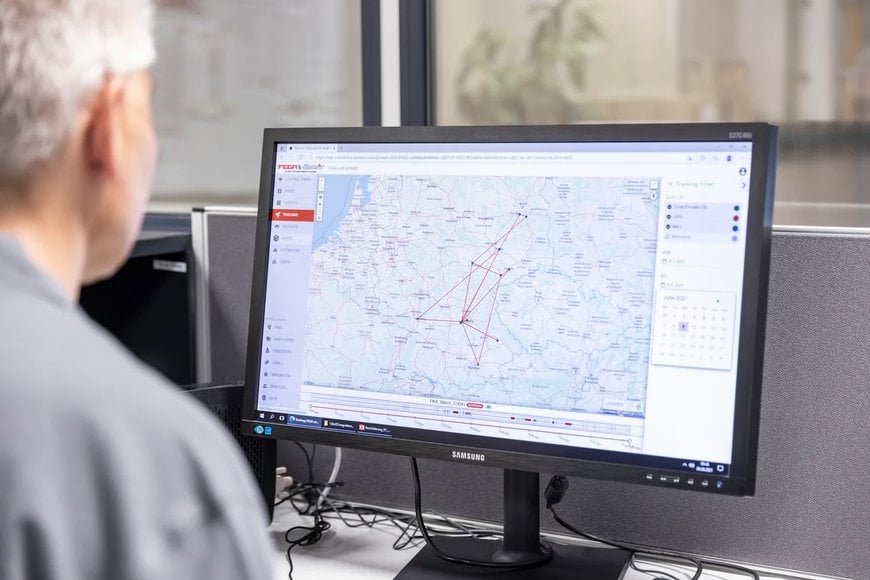

Each device sends asset location data to an online web application. At any time, the FEGA & Schmitt team can use the application to gain end-to-end visibility to the logistics process and optimise delivery processes. Retail customers also access the web application for real-time insights into the location of their shipment, which helps improve their end-user experience.

Once the goods reach the destination, the empty smart Wanzl roll cages are folded into an L-shape to save space, pushed into each other, and returned. Permanently monitored and optimised rotations ensure the safe, timely return of the roll cages to FEGA & Schmitt at lower cost.

"Our customers get an overview of the distribution of their logistics assets throughout the supply chain at all times. Manual inventory management is replaced by an automatic and continuous inventory across all relevant locations. Critical processes and parameters are monitored automatically." Christian Trösch, Head of Sales at BOX ID Systems.

Remarkable business outcomes

Since deploying IoT-enabled roll cages on half of their fleet to improve asset tracking across its logistics network, FEGA & Schmitt has experienced remarkable business benefits. Greater visibility of the logistics network has improved transportation efficiency and asset utilisation, reduced losses and damages, and helped the company achieve time and cost savings.

FEGA & Schmitt employees can record the status of a roll cage by scanning a QR code on it with a smartphone or other mobile device. This process allows the management of the asset status across the distribution network with categorisations including “damage report,” “service/repair,” or a distinction between “full” and “empty.” Employees can load photos of damaged assets, or needed spare parts to the web application, which significantly simplifies spare parts management.

The future of FEGA & Schmitt’s smart roll cage fleet

Convinced by the benefits and strong ROI, FEGA & Schmitt is readying to connect its entire roll cage fleet and connect more diverse IoT-enabled loading equipment, including parcel roll containers, picking trolleys, long goods racks, and system pallets.

www.sigfox.com