www.magazine-industry-usa.com

05

'21

Written on Modified on

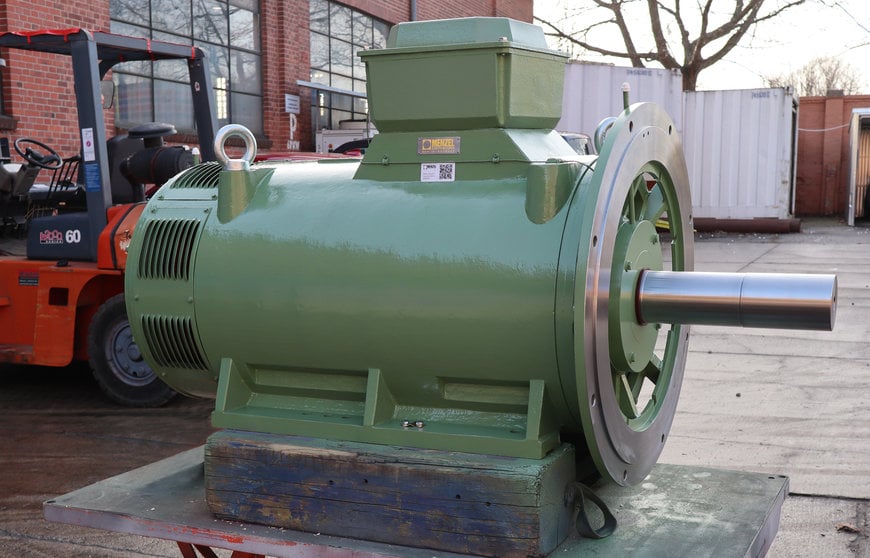

Asynchronous generator with special shaft for Pelton wheel

Menzel Elektromotoren has built an asynchronous generator with a special shaft and a special flange for operation on a Pelton wheel in a Scandinavian hydroelectric power plant.

The large radial forces acting on the shaft end in this application had damaged the existing generator to the extent that it was a total write-off. The customer required a more robust shaft construction to avoid such damage in the future. In addition, the new generator had to be identical to the old one and have the same electrical parameters. Menzel’s subsidiary Franz Wölfer Elektromaschinenfabrik designed and manufactured a shaft made of 42CrMo4 high-tensile strength special steel, reinforced on the turbine side. The concentrated collaborative expertise within the Menzel Group made it possible to quickly prepare a verified offer and complete the generator within two and a half weeks.

Menzel could deliver fast thanks to clever warehousing: a prefabricated three-phase asynchronous generator met the requirements of the application in the hydroelectric power plant. Menzel merely designed and manufactured a new bearing shield for the reinforced shaft and bearing. This generator order came in through Menzel’s Swedish subsidiary, which, like numerous offices and partners around the world, provides customer-oriented advice and service.

More about asynchronous and synchronous motors: https://www.menzel-motors.com/specialized-motors/generators/

www.menzel-motors.com