www.magazine-industry-usa.com

17

'13

Written on Modified on

Slimline: new AKD-N distributed servo drives

Kollmorgen: single-cable connection technology further developed – resulting in 80% less cable required

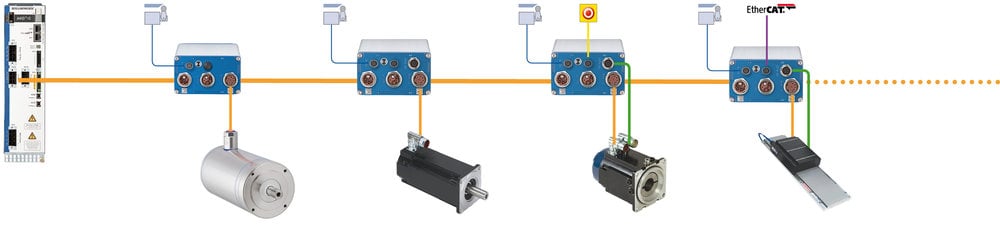

AKD-N is the new distributed servo drive generation from Kollmorgen. The drive system comprises robust IP67-rated controllers, which are positioned in close proximity to the motor and supplied by a central power module located in the switchgear cabinet. The 11 mm diameter hybrid cable perfectly delivers the power as well as the fieldbus communication to the AKD-N. The controllers can therefore be operated directly in series via DC bus connection without an additional supply, covering power ratings of up to 4 kW. Safe Torque Off is integrated into the range as standard and can be deactivated on an individual or collective basis. Typical fields of application of the new devices include packaging machines and production systems in the food and beverage industry.

Out of the cabinet and hygienically packaged directly on the machine, the distributed AKD-N servo drives significantly reduce cabinet volumes and cabling effort - depending on the application in question, savings of over 80% can be achieved. In this case, Kollmorgen has opted against hybrid motor controller units. The improved thermal properties of the controllers positioned in parallel but spatially separate prevent derating and, in comparison to directly combined solutions, offer 100% power. Furthermore, integrated combinations are predominantly focused on the motor type, which actually restricts the optimum design of an application, especially as these units are less flexible in terms of installation due to their design features. As the AKD-N is able to connect to rotary servomotors as well as direct drive linear and rotary types, there is maximum scope for design where performance and power are concerned.

Indeed, the distributed servo technology can be combined with the centralized format just as easily. Background: when it comes to distributed use, the only differences to be seen on the well-established AKD devices are on the outside. As such, there are no real surprises in terms of their function, programming and integration into the engineering system. Rather, Kollmorgen has fully converted the IP20 switchgear cabinet series into to a system offering a high protection class – combined with intelligent AKD PDMM servo drives, as well as integrating drive-based PLC and motion control. Single cable technology is also available between the servo controller and the motor. The advantages: reduced cabling, a high degree of flexibility through use of single standard cable for power and control across all feedback devices for overall decreased hardware costs as well as improved cleaning options for machines.