www.magazine-industry-usa.com

09

'20

Written on Modified on

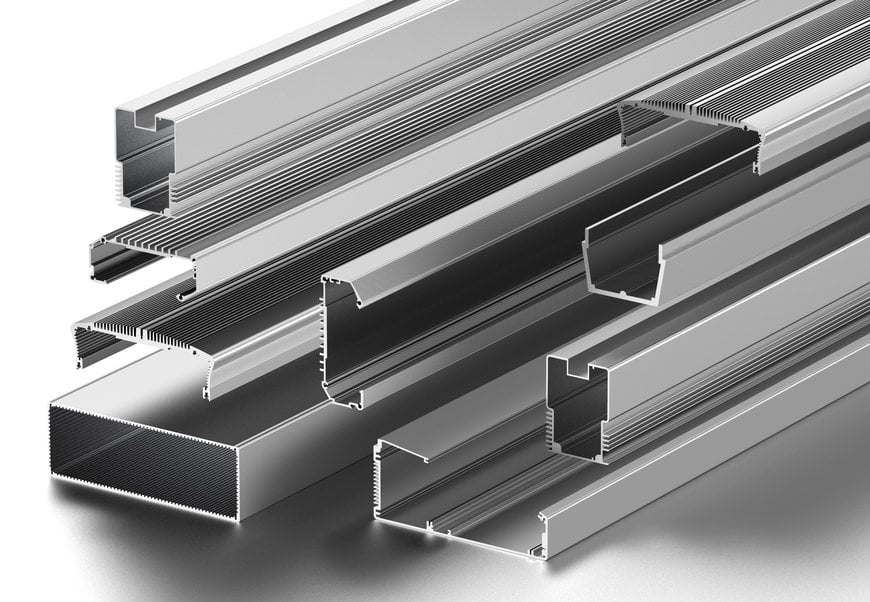

Customized extruded profiles for cases

The basis of the cases from Fischer Elektronik is largely made up of profiles made from the wrought aluminum alloy EN AW 6060.

The case profiles produced using the extrusion process are temporarily stored at Fischer Elektronik in 3 m long cuts under professional ambient conditions. This gives the customer the opportunity to have customer-specific profile cuts in addition to the standard case lengths. In addition to profiles from the standard portfolio the customer has the option of having profile solutions specially adjusted to the application.

Here the customer has the opportunity to design the profile as far as possible according to his own ideas. In addition to the classic parameters such as width and height many functional contours such as T-slots, threaded channels, cooling fins or guide grooves can be incorporated. As a result the installation space can be optimally used and subsequent mechanical processing can be reduced or costs can be saved. Furthermore Fischer Elektronik offers its customers technically competent and comprehensive advice on the design of a special profile.

The great vertical production range of Fischer Elektronik GmbH & Co. KG fulfills almost all wishes. This can be mechanical processing by milling, punching, laser cutting or the insertion of press-fit connectors as well as upgrading the surface by grinding or blasting.

To coat the surface, the customer can choose from anodizing in different colors, electrically conductive transparent passivation, lacquering and powder coating. Fischer Elektronik also offers UV digital printing, digital sub-anodize printing, screen printing and laser labeling of all case components.

www.fischerelektronik.de