www.magazine-industry-usa.com

24

'13

Written on Modified on

Norgren to showcase high-quality components and complete systems for the CNG industry at NGVA Europe

International market leader in pneumatic motion and fluid control technologies, Norgren, will showcase its components and system solutions for the compressed natural gas industry, at NGVA Europe, Gothenburg on June 11-13 (stand C15).

Jon Taylor, Global Sector Head - Energy at Norgren comments: “NGVA Europe presents the ideal platform for Norgren to showcase its market-leading energy solutions to the global CNG sector. We have an unrivalled range of high quality components and complete system solutions which deliver Engineering Advantage by meeting the specific requirements of the compressed natural gas industry.

“With operating pressures up to 350 bar, all have been designed to help increase energy efficiency, improve the environment by simplifying the delivery of CNG into vehicles and eliminating wastage, and optimise the safety of CNG delivery systems.”

CNG manifold solutions

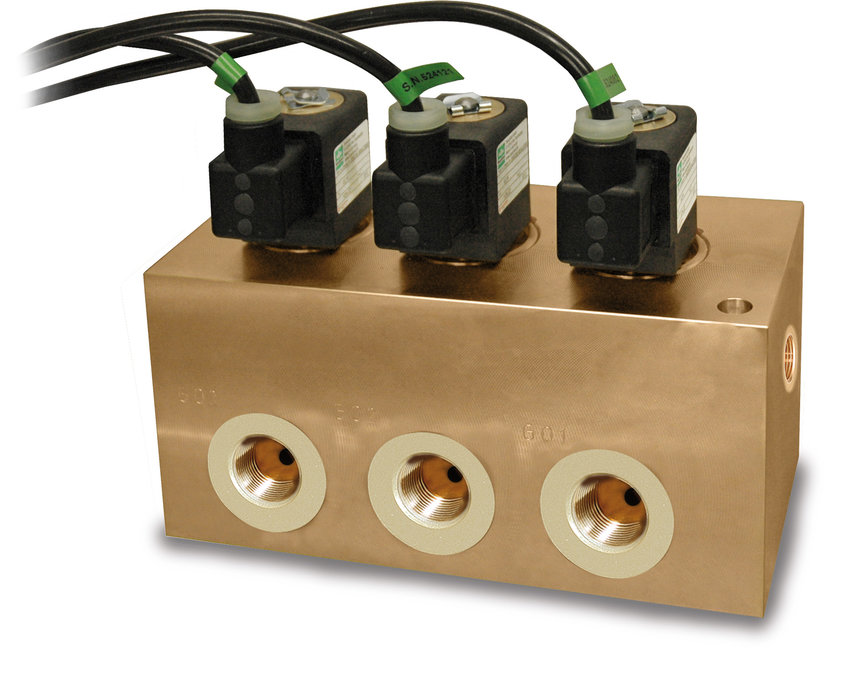

With 75 years’ experience manufacturing sophisticated solenoid valves, Norgren is confident in the reliability and performance of its products, and is now providing valued added solutions by incorporating the company’s proven valve technology into customised valve manifolds.

Typical systems found in priority panels and dispensers utilise the CNG to drive rotary actuators, which in turn open and close ball valves. Alternatively, a compressed air infrastructure is installed, and compressed air is used to drive the rotary actuator.

By adopting the Norgren solution – comprising manifold solutions from Buschjost - each CNG line previously consisting of ball valve, rotary actuator and pilot solenoid is replaced by a solenoid valve manifold with integrated check valves and filters. Benefits include a significant increase in system reliability, reduced installation costs, simplified servicing, zero wasted gas vented to atmosphere, no requirement for a compressed air infrastructure, a cut in component count and fittings, and a reduction in potential leak paths. The CNG manifold solution typically encompasses three, six and eleven station manifolds depending on the application.

High pressure control solutions

Norgren offers proven solutions for high pressure gas control on the outlet from the compressor and in downstream pressure reduction applications such as the dispenser. Products on the Norgren stand will comprise high pressure control solutions from Norgren’s IVP range, incorporating spring loaded regulators that control the outlet pressure over a range of inlet pressures and flows, and dome loaded regulators that function in the same way but use pressure in the dome of the regulator to apply the force to the control element.

Also on display from Norgren’s IMF range are proportional pressure control valves and dome loaded regulators that control the output pressure via an electrical signal. Additionally pressure relief valves will be displayed where the valve opens to the atmosphere if the inlet pressure rises above the pre-set point.

For further information visit www.norgren.com.