www.magazine-industry-usa.com

13

'13

Written on Modified on

Complex movements made easy

Baumüller adds "Coordinated Motion" to its software toolbox

At the Hannover Messe, Baumüller will be presenting its new software library in action.

With its "Coordinated Motion" components library, Baumüller is now making robot and CNC functions usable within Motion Control SPS. This makes it easy for users to make coordinated movements on several axes. Only the programming languages included in IEC 61131 are used. Programming of path movements is done using the G-Code conforming to DIN 66025, which is widely known in the CNC world.

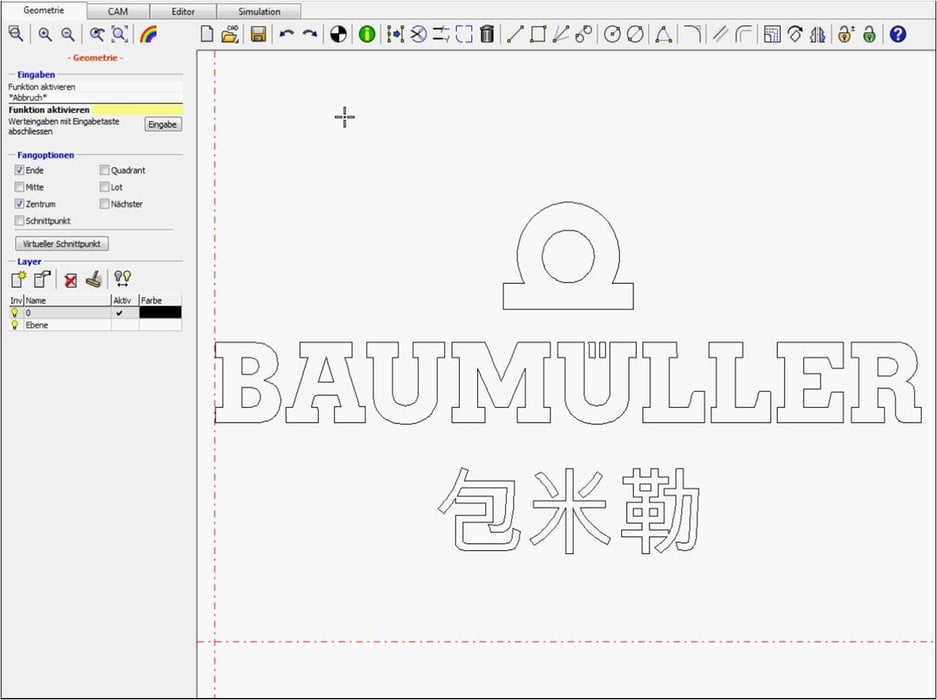

By this means, the user can define trajectories, speeds and the workpiece coordinate system entirely freely within the workspace. The CNC program is loaded into the SPS system as a simple text file and can be as large as required. Thus data from CAD/CAM systems can also be used for programming the machine.

The pre-programmed components and the combination of CNC and SPS functionalities saves machine builders programming time and spares them the cost of additional hardware.

From inside the Baumüller software toolbox you can find all the basic functions you need as standardized and validated components or already packaged together into sector-specific specialized modules. The combination of these basic functions allows you to create applications using the ProMaster engineering framework without effort-intensive programming, mainly by setting values for the parameters specific to the machine you are using.

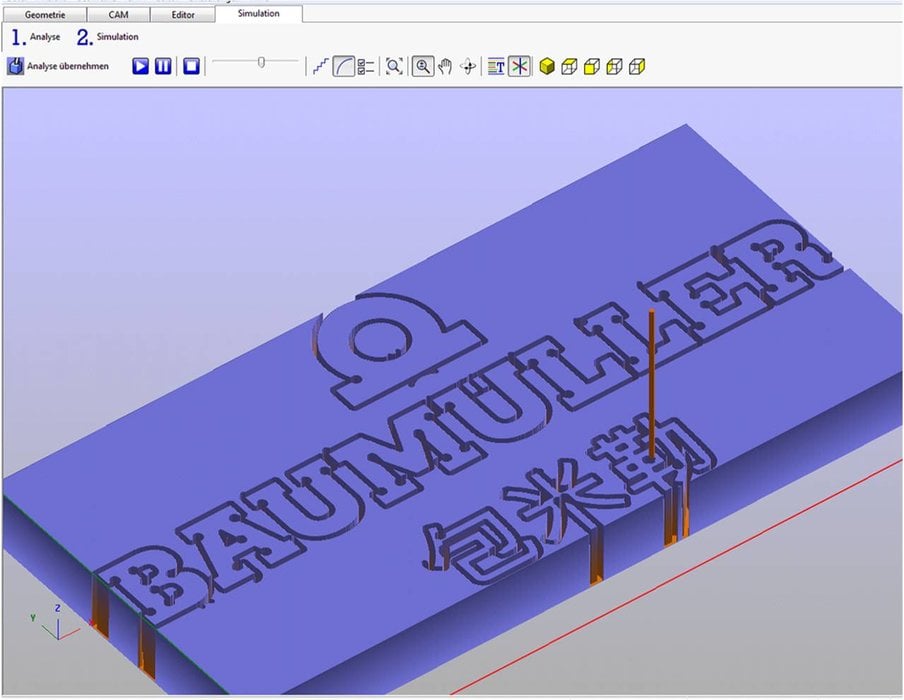

Figure 2: Simulation of processing