www.magazine-industry-usa.com

22

'20

Written on Modified on

Milling cast and steel parts more cost-effectively

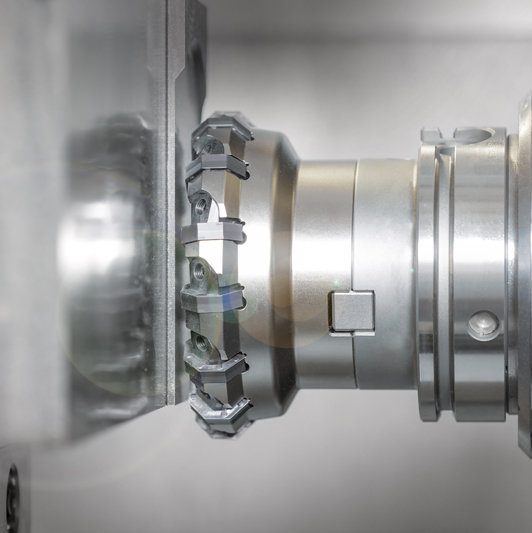

Whether they’re producing turbochargers, steering knuckles or cylinder blocks, customers can mill their cast and steel parts considerably more cost-effectively with the radial insert milling programme from MAPAL than with the previously available solutions. Since the product launch in 2018, there have been a large number of measurable successes resulting from the use of the tools in the series production.

Let’s take a quick look back: MAPAL first showcased a product programme for milling with compressed radial indexable inserts at the AMB exhibition in Stuttgart in 2018. “This move was the natural next step towards our aim of being a comprehensive service provider for our customers,” explains Dr Wolfgang Baumann, who is responsible for the product programme of tools with ISO elements at MAPAL. “But our aim isn’t just to provide the customer with all their machining needs in terms of tools and chucks – we also want to offer them added value through our solutions,” adds Baumann. Accordingly, the development process of the new tools was comprehensive and detailed.

“Before this milling programme, our focus was mainly on supporting customers with specific application needs, such as providing support for high levels of stock removal or unstable conditions,” explains Dr Baumann. This machining was mostly carried out using ground tangential indexable inserts. “We’re obviously not the first company to offer a radial milling programme. We’ve simply plugged a gap in our portfolio,” admits Baumann. However, he further adds: “Through our work with special applications, we’ve accumulated extensive in-depth knowledge that has been incorporated into the development of our compressed radial blades. They therefore offer considerable added value and, in particular, economic benefits for users.”

“The success stories that we’ve gathered with our radial insert milling programme prove that our meticulous work is paying off for our customers today,” explains Dr Wolfgang Baumann enthusiastically. In many applications, the cost per part (CPP) was considerably reduced. There are several reasons for this: “In many cases, other tools were superseded once we had analysed the application and selected the optimal tool,” Baumann explains.

“For some applications, our tools now machine significantly more parts until the blades have to be replaced. And in some other machining operations, the same machining times per part can be achieved with fewer blades. However, there are other cases where we can achieve considerably higher cutting data with more blades. We sometimes rely on indexable inserts with more cutting edges, thanks to which each individual indexable insert can be used for considerably longer.”

By way of example, three machining operations on customer parts demonstrate the added value that the radial milling programme offers:

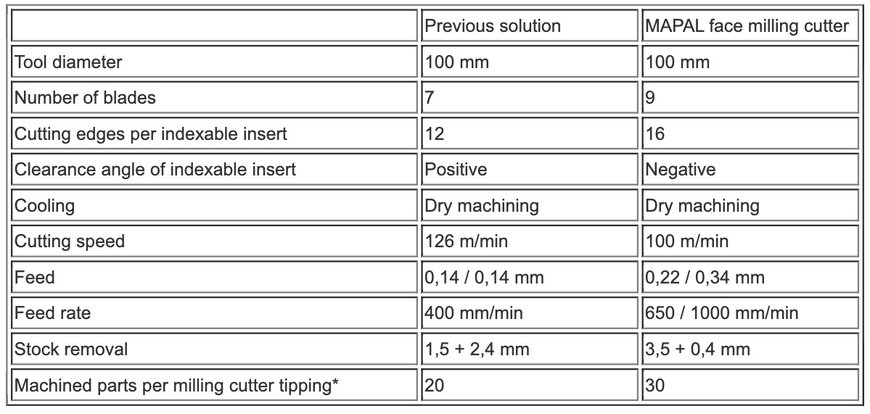

1. Turbocharger machining

Face milling of the hot side made of stainless steel

The face milling cutter with nine blades from MAPAL replaces the previously available face milling cutter with seven blades.

Thanks to the MAPAL solution, 50 % more parts are milled in total, the cycle time is considerably reduced and the costs per part are 44 % lower than previously.

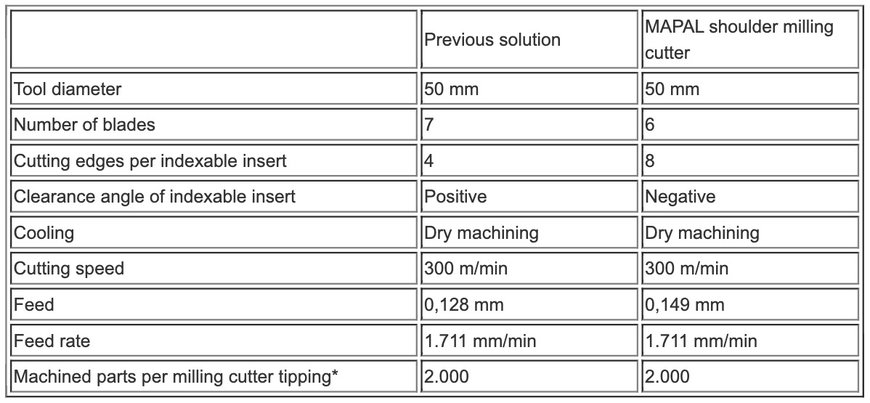

2. Steering knuckle machining

Shoulder milling/roughing of various connection points on a steering knuckle made of cast iron with spheroidal graphite – stock removal of between 2.5 and 4.5 mm

The shoulder milling cutter with six blades from MAPAL replaces the previously available shoulder milling cutter with seven blades. Despite its negative clearance angle, it achieves the same tool life as the previously used solution with positively aligned indexable inserts.

Although the new milling cutter machines exactly the same number of parts as the previous one, the costs per part are reduced by more than half – by 58 %.

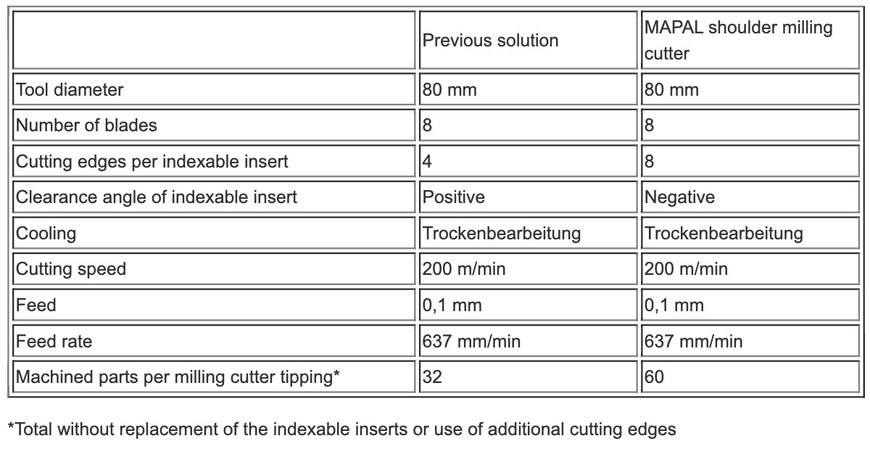

3. Cylinder block machining

Shoulder milling/roughing of various surfaces on cylinder blocks made of cast iron with lamellar graphite – stock removal of between 2 and 4 mm

The eight-edged shoulder milling cutter from MAPAL replaces a shoulder milling cutter which also has eight edges.

The tool life of the milling cutter from MAPAL is considerably longer than that of its predecessors under identical operating conditions – even with its negatively aligned indexable insert. And on top of that, the cost per part is also reduced by 58 %.

www.mapal.com