www.magazine-industry-usa.com

25

'20

Written on Modified on

Go West! GEA hygienic centrifugal pumps launch in USA

“Go West” is the slogan for GEA's range of pumps, which aims to conquer the US market in 2020. Of course, there is nothing as peaceful and free as the Village People suggested in the 1970s or the Pet Shop Boys in the 1990s.

A tough market, according to GEA experts Martin Zickler and Dave Medlar, where it is better to start planning from the back in order to make everything right from the beginning. That's why they first built up the service network and a local assembly and then made a promise: GEA pumps will bring a new level of quality, efficiency and hygiene to the US dairy, pharmaceutical, food and beverage markets.

GEA acquired Hilge, a leading German pump manufacturer, in June 2015. Since then the company has been integrated into GEA and has benefitted from its engineering experience and global network of customers, suppliers and agents. Now that the pumps have received 3-A certification, the time is right to meet the US market head on.

Martin Zickler is the product manager for hygienic pumps, based in Germany. He worked with Hilge before the GEA acquisition. “The old company had no footprint in the USA,” he said. “But now that we have the backing of GEA and a comprehensive service and distribution network in the country, we are ready to take on the challenge.”

Michael Brandt is the business development manager charged with the job of making the US launch a success. He said that he had never had any doubts about the quality of the pumps and the opportunities for them in the US, but he had to make sure that the service and support structure was up to American standards before introducing them to the market.

Get ahead by looking back

“GEA pumps are strong, reliable workhorses but, for the American market, service is critical,” he explained. “We need to be able to respond quickly to our customers and provide a fast spares service. We also needed a reliable distribution network as customers need to know that if they require assistance, they can get the relevant expertise quickly.”

Dave Medlar, head of sales valves & pumps USA and his team have been working hard to get the support network in place before the product launch. “Of course, providing excellent service is always work in progress but I am now confident that we are ready,” he said. “We have a global reputation to maintain; when people buy a GEA product, they know it’s going to be supported well, also during the entire service life of a pump.”

Hygienic approach becomes a must-have

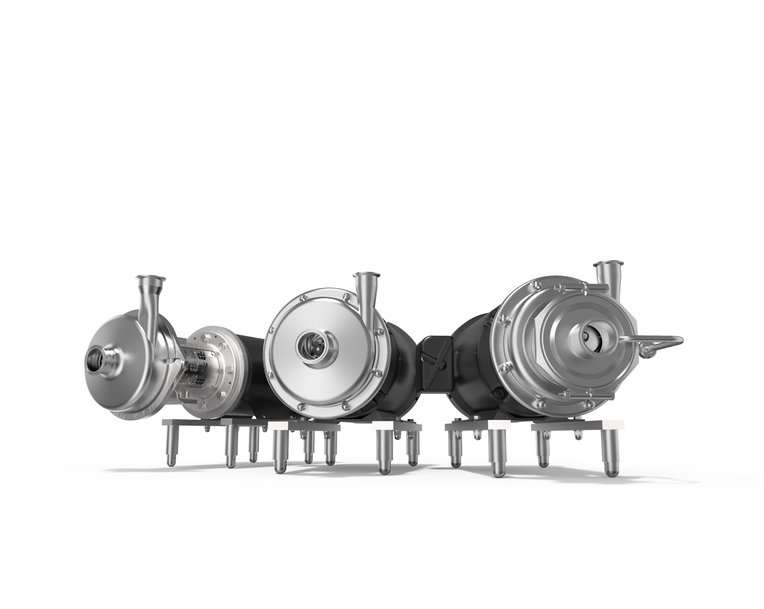

The GEA centrifugal pumps have a unique impeller design that sets them apart from normal centrifugal pumps. “We have pushed the impeller towards the front making it more efficient and the mechanical seal easier to cool. It mimics a closed impeller but can still be used in the pharmaceutical industry and wherever sanitary conditions are required,” said Martin. “This means the pump is easier to clean and can handle a much wider range of liquids.”

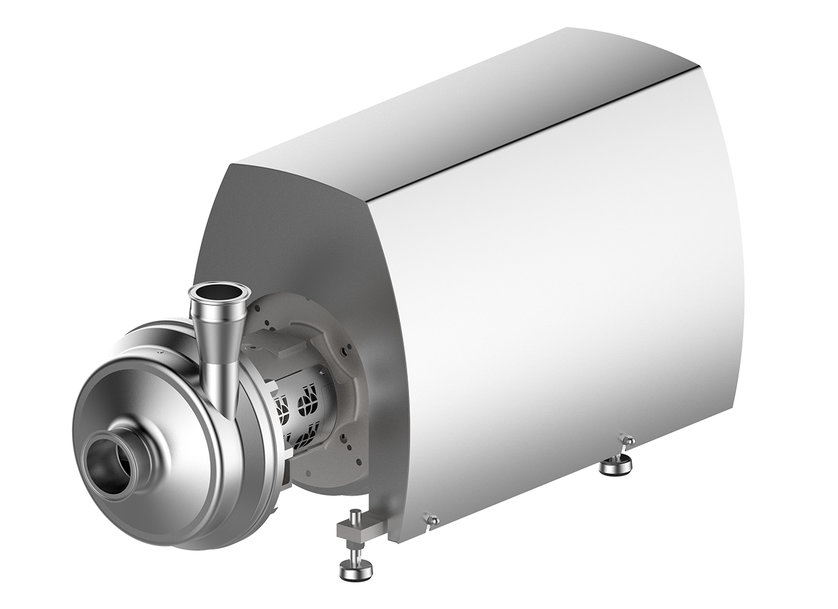

In addition, GEA pump housings are manufactured by deep drawing, not casting. This provides a much higher quality surface finish without blow holes in which bacteria can collect. Although this has been a feature demanded largely by the pharmaceutical industry in the past, the food and beverage market is increasingly requiring a more hygienic approach throughout all aspects of its production.

Engineering excellence that allows customization

Although the product’s unique features are impressive, and it has a great reputation for reliability, Michael sees an even stronger sales proposition in the engineering experience of the GEA group. “It’s like an engineer’s toolbox,” he said. “We know that all applications are different and it’s flexibility that our customers need. Because we are engineers, not just suppliers of components, we can adapt the pumps to fit virtually any application. This might include, for example, different fittings or mountings, a more robust design or even providing the pump on a trolley. We look at the application, then work out what the customer needs are.”

Key target markets

GEA sees perhaps the greatest immediate opportunity for GEA pumps to be in the dairy industry. “For example, our pumps are ideally suited for transferring cheese curd,” Martin said. “This is an application that usually employs a positive displacement pump, but our unique impeller and pump design makes our centrifugal pumps (e.g. the GEA Hilge HYGIA) perfect for the job. They are less expensive to buy than positive displacement pumps, have fewer parts so are easier to maintain, and the spare parts are much cheaper too. This is going to be a very strong market for us.”

This is the right time

Again, there's a song that nobody has ever connected to a pump program: "This is the right time" by Lisa Stansfield. But GEA has big plans, has prepared intensively for this and therefore they deserve harmonious chords. Of course, there has to be a question as to whether now is the right time to be tackling a new market especially as

the main target, the dairy industry in the USA, has been on a slow-down for some time. But GEA takes a positive view. “The lower level of activity will give us time to settle into our new role,” he said. “The next upswing will come soon enough and we will then be prepared to make the best of it when it does.”

2- Perfect job for cheese curd: The GEA Hilge centrifugal pumps have a unique impeller design that sets them apart from normal centrifugal pumps.

3-Designed for system pressures up to 64 bar, the GEA Hilge HYGIA H can now also cover membrane filtrations in the dairy industry.

www.gea.com