www.magazine-industry-usa.com

13

'12

Written on Modified on

Waterproof overload protection

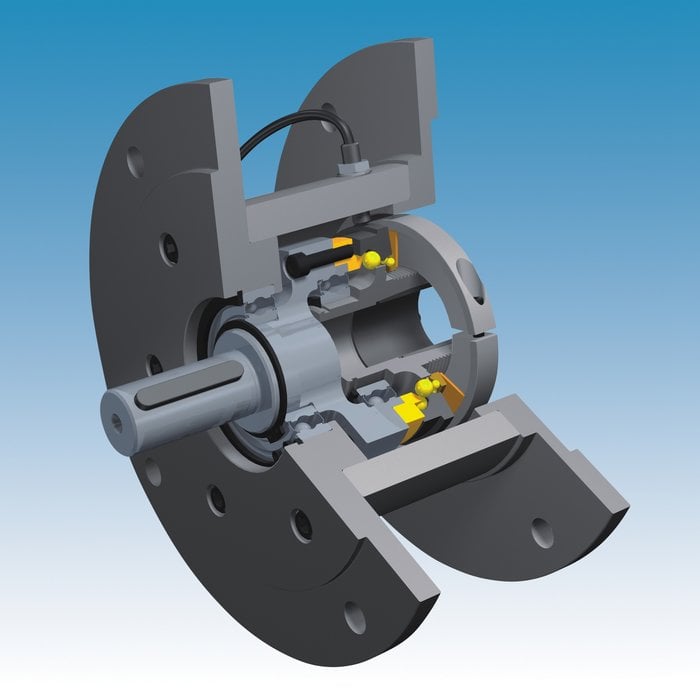

Increased power on corrosion-protected torque limiting clutches

Corrosion-protected torque limiting clutches for protection against damage caused by overload have proven their worth in numerous applications, in which moisture and dirt are part of the everyday ambient conditions. In case of malfunctions and collisions, they limit the torque in the drive line to a defined value, thereby preventing expensive damage, downtimes and repair work.

The housed clutches of the EAS®-HTL series can also be retrofitted into already existing constructions and systems. The dimensions of the housing flanges and the shafts correspond to the standards IEC/B5 and NEMA. The extremely short construction length of the EAS®-HTL facilitates integration into the existing drives. Furthermore, the high level of rigidity of the solid steel housing permits the attachment of hanging loads. The housing seal prevents not only the penetration of moisture and dirt, but also the washing-out of lubricants from the installed EAS®-NC or EAS®-Compact® torque limiting clutches.

In malfunction-free operation, these torque limiting clutches transmit the torque backlash-free over the entire service lifetime; therefore they are also suitable for demanding and dynamic drive concepts. They are set to the torque requested on order at the place of manufacture. If this torque is exceeded due to overload or collision, the clutches disengage and separate the input and the output in only a few milliseconds. An integrated limit switch recognizes the disengagement movement and emits a signal, which can, for example, be used to switch off the drive. The disengagement time depends on the rigidity of the axis as well as on the force and speed of the collision.

On disengagement, cup springs with a negative characteristic curve ensure that the torque drops immediately and not only after an excessive increase in torque; something that has to be accepted when using many other ball detent torque limiting clutches. The re-engagement behaviour after overload differs depending on the design of the torque limiting clutch integrated into the EAS®-HTL.

Ratchetting clutches re-engage automatically at any position and are ready for operation again immediately. Synchronous clutches behave similarly, except they can only engage at exactly-defined input and output side positions. Overload clutches, however, remain disengaged until they are re-engaged manually or using suitable devices. The stored energy of the rotating masses can run out freely. The disengaging design is preferred for large mass moments of inertia and high speeds.

Product figure:

File: F-5-39-Bild1.jpg

The dimensions of the housing flanges and the shafts according to the standards IEC/B5 and NEMA even allow retrofitting of the EAS®-HTL into already existing constructions and systems.