www.magazine-industry-usa.com

02

'26

Written on Modified on

Rail brakes enable rapid roller replacement in laminating units

mayr power transmission rail brakes minimize downtime by securely fixing machine frames during fast roller changes in continuous laminating operations.

www.mayr.com

SAUERESSIG has evolved from being a manufacturer of printing and embossing rollers to becoming a highly innovative machine manufacturer with a diverse product range.

In a large laminating unit by SAUERESSIG Engineering for laminating steel strip on both sides, rubber rollers press a protective PET film onto hot steel strip. Despite cooling, these rubber rollers do wear down and need to be replaced regularly. Four profiled rail brakes by mayr® power transmission ensure that the laminating process, which takes place 24 hours a day, only has to be interrupted briefly to replace the rollers.

SAUERESSIG began manufacturing printing and embossing rollers for the packaging and printing industry around 70 years ago. Today, the company is a highly innovative mechanical engineering company with a diverse portfolio. As a leading full-range supplier of calendering, embossing and rotary processing systems in standard and special designs, the company supplies a wide range of industries.

The machine solutions include both complete production lines and customized systems for embossing, finishing, coating, smoothing, perforating and calibrating sheet materials such as paper, film or metal sheets. The company offers comprehensive expertise from the initial idea to the final customized solution, including planning and designing mechanics, drive and automation technology, pre-assembly and commissioning in the factory, and final approval at the customer's premises.

In a large laminating unit by SAUERESSIG Engineering for laminating steel strip on both sides, rubber rollers press a protective PET film onto hot steel strip. Despite cooling, these rubber rollers do wear down and need to be replaced regularly. Four profiled rail brakes by mayr® power transmission ensure that the laminating process, which takes place 24 hours a day, only has to be interrupted briefly to replace the rollers.

SAUERESSIG began manufacturing printing and embossing rollers for the packaging and printing industry around 70 years ago. Today, the company is a highly innovative mechanical engineering company with a diverse portfolio. As a leading full-range supplier of calendering, embossing and rotary processing systems in standard and special designs, the company supplies a wide range of industries.

The machine solutions include both complete production lines and customized systems for embossing, finishing, coating, smoothing, perforating and calibrating sheet materials such as paper, film or metal sheets. The company offers comprehensive expertise from the initial idea to the final customized solution, including planning and designing mechanics, drive and automation technology, pre-assembly and commissioning in the factory, and final approval at the customer's premises.

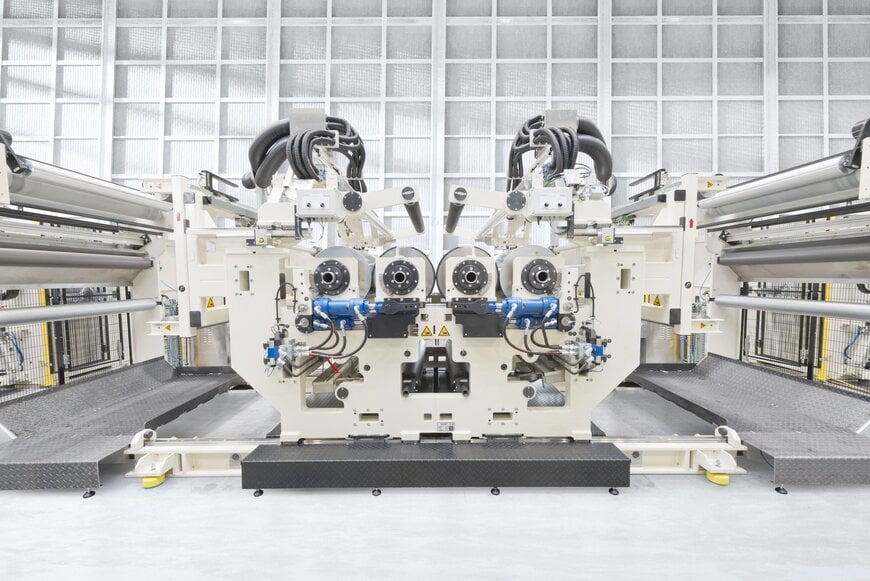

SAUERESSIG's large laminating unit coats both sides of the steel strip with a protective PET film

One such customized system, no less than six metres long and around four metres wide, coats a steel strip on both sides with a thin protective PET film. Harald Bartsch, Head of Design/Expert Advisor at SAUERESSIG Engineering, describes the machine's design concept as follows “The complete laminating unit consists of two nearly identical, symmetrically arranged side frames, each with a rubberized laminating roller and a contact cooling roller. For laminating, the steel strip moves vertically between the two laminating rollers through the laminating unit at a conveying speed of up to 250 m/min. The laminating rollers press the film onto the hot steel strip from both sides.”

The steel strip's high temperatures of up to 260 °C heat up the rubber coating on the laminating rollers. Water-cooled contact rollers dissipate this heat and limit the rubber coating’s temperature to a maximum of 90 °C. Despite the cooling, the rubber linings of the laminating rollers are subject to wear and must be replaced regularly. “As the laminating process should ideally be running continuously all year round and 24/7 without interruption,” explains Harald Bartsch, “the time required to replace the laminating rollers must be kept as short as possible. Therefore, the laminating unit is designed in such a way that the automated roller replacement only takes half an hour.”

The laminating unit consists of two symmetrically arranged side frames. Both side frames are mounted onto profiled rail guides and can be separated axially to replace the worn laminating rollers. While the coating process is in progress, profiled rail brake of the ROBA® guidestop® series by mayr® power transmission hold the two system parts in position backlash-free and with high rigidity. To replace the rollers, these safety brakes are released hydraulically, the two machine halves can be moved apart via rack and pinion gears and the laminating rollers can be replaced.

Profiled rail brake of the ROBA® guidestop® series by mayr® power transmission hold the two system parts of a large laminating unit in position backlash-free and with high rigidity.

The ROBA® guidestop® profiled rail brake serves as a reliable safety brake and backlash-free clamping unit. It can brake movements safely and quickly and clamps the axes rigidly and backlash-free.

Just like all safety brakes by mayr®power transmission, the profiled rail brakes also work according to the fail-safe principle. This means they are closed in de-energised condition. The ROBA® guidestop® brakes use pre-tensioned cup springs to press the brake shoes against the 'waist' of the profiled rail, thus clamping it in place.

The hydraulic brake design used in the SAUERESSIG laminating unit is released using a nominal pressure of 70 bar. This is comparatively low in relation to the very high holding forces. The brake mechanism is dimensioned for relatively large strokes. As a result, the brake can compensate for production tolerances on the profiled rails without losing braking force. The ROBA® guidestop® safety brakes are equipped with two independent brake circuits: This allows for either double holding forces or a redundant design.

The profiled rail brakes are therefore directly mounted onto the masses which are to be braked or held. This minimises the risk of hazards, particularly with gravity-loaded axles, as drive elements between the motor and the moving mass, such as spindles, spindle nuts, shaft couplings and gears, do not affect safety. This is different for concepts with motor brakes, as all drive elements must transmit the braking torque to the carriage. Furthermore, every element between the brake and the carriage has a negative effect on rigidity. ROBA® guidestop® safety brakes are therefore considerably more rigid than motor brakes, rod brakes or band brakes, which are often subject to backlash.

ROBA® guidestop® safety brakes by mayr® power transmission are available in pneumatic or electromagnetic versions in addition to the hydraulically opening design. The hydraulically releasing ROBA® guidestop® series covers nominal holding forces from 5000 to 34000 N with four sizes. The pneumatically releasing version offers the greatest variety of options: Six sizes with nominal holding forces from 700 to 15000 N are available in the standard product range. Both versions (i.e. pneumatically and hydraulically releasing) are available for all common linear guides. Electromagnetically opening rail brakes do not require any pneumatic or hydraulic equipment. mayr® power transmission developes this variant on request, customizing it for the respective application.