www.magazine-industry-usa.com

08

'12

Written on Modified on

Maintenance-free brakes for wind turbines

The application of safety brakes in wind turbine pitch drives requires extremely conscientious dimensioning and precise knowledge of braking torque tolerances. If these prerequisites are fulfilled, high-quality brakes will work without requiring any maintenance across their entire service lifetime.

The pitch drive brakes have the task of securing the rotor blades against twisting once they have been angularly positioned by the gear motors. This rotor adjustment must always function, even if, for example, the power supply has failed. In this case, the motor can be supplied by a battery or capacitor. If no such emergency supply is available for the brake, the motor is designed so that it is capable of turning the rotor blades against the braking force to bring them into a safe position (out of the wind) even when the brakes are applied.

Well-founded knowledge of the braking torque tolerances for the brakes used is particularly important in such cases. On the one hand, a sufficient braking torque must be provided to hold the rotors; on the other hand the maximum motor torque must not be exceeded so that it remains possible to turn the blades to a safe position against the applied brakes. Of course, this must be ensured in any ambient conditions occurring during normal operation, such as for example at a relative air humidity of > 90 % or at temperatures well below freezing point. Offshore, mechanical components are subjected to additional strain due to the aggressive, salty air.

mayr® power transmission has equipped its maintenance-free wind power brake, based on the tried and tested ROBA-stop®-M brake, for these tough conditions. Metal surfaces, in particular, had to be protected against corrosion. In addition to rustproof components such as in thrust springs, friction linings especially developed for these applications combined with special non-corrosive counter friction surfaces have proven their worth.

All function-relevant values for each individual mayr® brake are inspected and documented before delivery in order to guarantee maximum operational safety of the system. Countless tests in the company's own Development and Testing Department at the mayr® headquarters in Mauerstetten provide the basis for conscientious lifetime dimensioning, taking into account realistic and verified braking torque tolerances. In the meantime, the company has supplied more than 100,000 wind power brakes to renowned drive manufacturers for use in wind power plants, and has not, up to now, registered any failures.

Fig. 1

File: F-6-36-Bild1.jpg

The temperature and air humidity affect the braking torque of safety brakes. Therefore their application in wind turbine pitch drives requires extremely conscientious dimensioning and precise knowledge of the braking torque tolerances.

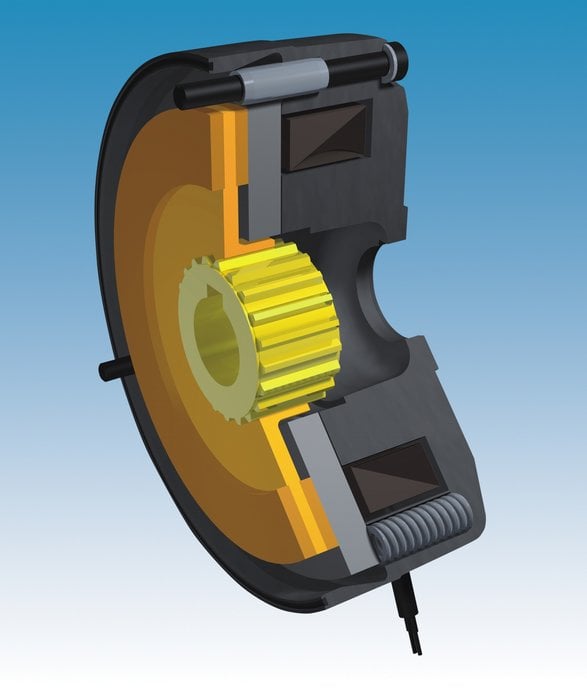

Fig. 2

File: F-6-41-Bild2.jpg

Pitch drive with angular gear and ROBA-stop® wind power brake.

Well-founded knowledge of the braking torque tolerances for the brakes used is particularly important in such cases. On the one hand, a sufficient braking torque must be provided to hold the rotors; on the other hand the maximum motor torque must not be exceeded so that it remains possible to turn the blades to a safe position against the applied brakes. Of course, this must be ensured in any ambient conditions occurring during normal operation, such as for example at a relative air humidity of > 90 % or at temperatures well below freezing point. Offshore, mechanical components are subjected to additional strain due to the aggressive, salty air.

mayr® power transmission has equipped its maintenance-free wind power brake, based on the tried and tested ROBA-stop®-M brake, for these tough conditions. Metal surfaces, in particular, had to be protected against corrosion. In addition to rustproof components such as in thrust springs, friction linings especially developed for these applications combined with special non-corrosive counter friction surfaces have proven their worth.

All function-relevant values for each individual mayr® brake are inspected and documented before delivery in order to guarantee maximum operational safety of the system. Countless tests in the company's own Development and Testing Department at the mayr® headquarters in Mauerstetten provide the basis for conscientious lifetime dimensioning, taking into account realistic and verified braking torque tolerances. In the meantime, the company has supplied more than 100,000 wind power brakes to renowned drive manufacturers for use in wind power plants, and has not, up to now, registered any failures.

Fig. 1

File: F-6-36-Bild1.jpg

The temperature and air humidity affect the braking torque of safety brakes. Therefore their application in wind turbine pitch drives requires extremely conscientious dimensioning and precise knowledge of the braking torque tolerances.

Fig. 2

File: F-6-41-Bild2.jpg

Pitch drive with angular gear and ROBA-stop® wind power brake.