www.magazine-industry-usa.com

29

'11

Written on Modified on

Measurable increase in productivity for cast iron machining

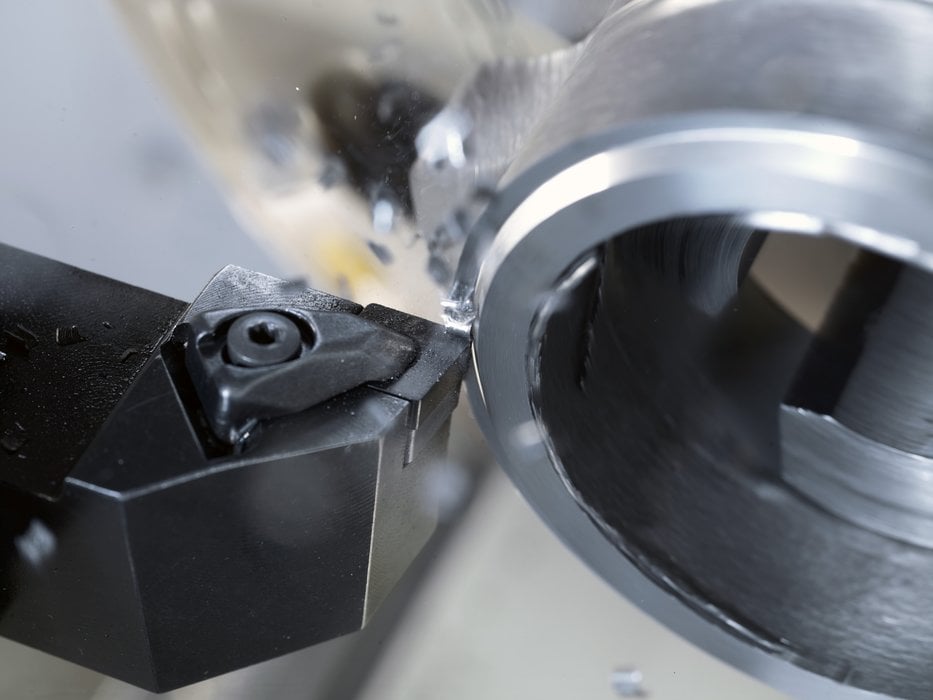

Global cutting tool manufacturer Seco Tools presents a new generation of turning products with the new carbide grades TK1001 and TK2001 - the tool of choice for demanding cast iron machining, hard and abrasive alloy machining. And, thanks to the unique patented Duratomic® technology, they open up a whole new world of increased machining security and performance.

The new grades TK1001 and TK2001 represent a completely new generation of tools for the turning of cast iron.

TK1001, Duratomic-coated grade, is predominantly and best used for grey cast iron machining which requires a high level of wear and abrasion resistance. The unique coating technology ensures higher wear resistance and longer tool life, improves edge line integrity and embodies high levels of deformation and heat resistance. When looking for long and reliable tool life under stable conditions, especially in grey cast iron, the new TK1001 Duratomic grade is the first choice. The Duratomic coated tungsten carbide of TK1001 is specially designed to achieve the highest productivity.

TK2001 is always used when challenging machining conditions require high durability and extreme stability of the cutting edges. Not least, but also because of the Duratomic technology, TK2001 is able to achieve peak performance in particular with regard to flank wear, even under unstable conditions or interrupted cuts. Thus TK2001 is the first choice for ductile cast iron, especially when targeting long, predictable tool life and a wide working window.

Both grades excel with regard to reliability particularly if there are variations in the material quality of the casting batches. TK1001 and TK2001 stand for a measurable increase in productivity – even under the most demanding machining conditions.

(Picture attached: TK_1.jpg – TK1001/TK2001 Duratomic inserts increase tool life and productivity)

TK1001, Duratomic-coated grade, is predominantly and best used for grey cast iron machining which requires a high level of wear and abrasion resistance. The unique coating technology ensures higher wear resistance and longer tool life, improves edge line integrity and embodies high levels of deformation and heat resistance. When looking for long and reliable tool life under stable conditions, especially in grey cast iron, the new TK1001 Duratomic grade is the first choice. The Duratomic coated tungsten carbide of TK1001 is specially designed to achieve the highest productivity.

TK2001 is always used when challenging machining conditions require high durability and extreme stability of the cutting edges. Not least, but also because of the Duratomic technology, TK2001 is able to achieve peak performance in particular with regard to flank wear, even under unstable conditions or interrupted cuts. Thus TK2001 is the first choice for ductile cast iron, especially when targeting long, predictable tool life and a wide working window.

Both grades excel with regard to reliability particularly if there are variations in the material quality of the casting batches. TK1001 and TK2001 stand for a measurable increase in productivity – even under the most demanding machining conditions.

(Picture attached: TK_1.jpg – TK1001/TK2001 Duratomic inserts increase tool life and productivity)