www.magazine-industry-usa.com

03

'18

Written on Modified on

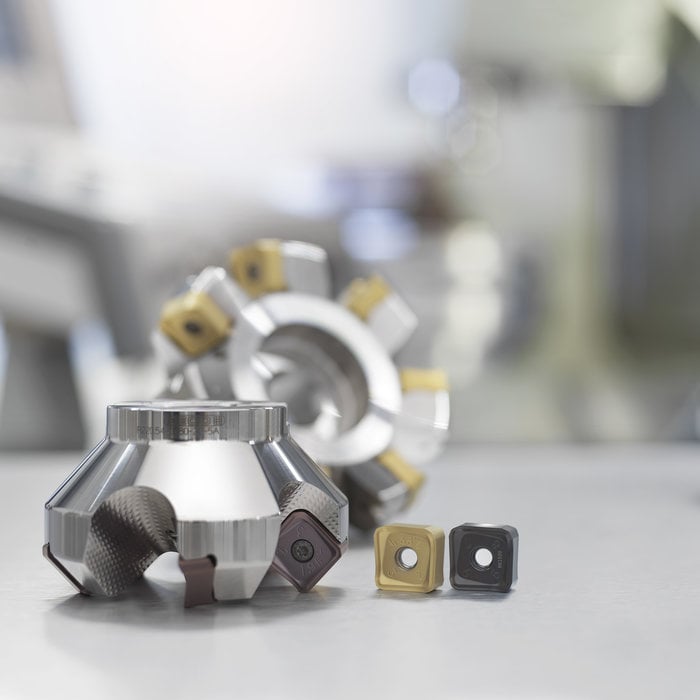

Double Quattromill® 22 of Seco Boosts Heavy-Duty Face Milling Operations

Seco's latest breakthrough in face milling cutters, the Double Quattromill® 22, significantly boosts metal removal rates and allows shops to push machine tools to their full milling potentials. The new cutter, for both roughing and semi finishing, features eight inserts with multiple cutting edges that cost-effectively increase depths-of-cut for high output.

The Double Quattromill® 22 comes in two different insert designs marked 45° and 68°, for depths-of-cut up to 9mm (0.350”) and 11mm (0.430”), respectively. Unlike those on standard tangential-type face mills, the Double Quattromill® 22’s double-sided inserts are extremely free cutting for lower cutting forces/machine power consumption and longer tool life.

Double Quattromill® 22 fits into the transitional area between easy and economical cutting. Choose cutter bodies in fixed-pocket and cassette styles, standard or close pitch and metric or inch versions. Seco also applied its new surface texture technology to the Double Quattromill® 22’s cutter body flute surfaces for enhanced chip control and evacuation as well as durability.

The Double Quattromill® 22 offers three insert ranges with various edges and grade options. The ME12 geometry works with superalloys and stainless steels. The M12 geometry comes in many grades for compatibility with most workpiece materials. The M18 covers steels and cast irons, which require heavier edge protection.

For more information on the Double Quattromill® 22, please contact a local Seco representative or visit our Double Quattromill® 22 product page.