www.magazine-industry-usa.com

06

'09

Written on Modified on

ROBA®-secustop, Safety brake for chain hoists in stage applications

Electric chain hoists for stage applications must comply with the BGV safety standards. Within these standards, there are various levels that determine the tasks for which this type of lifting gear is authorized. To comply with BGV-D8 Plus or BGV-C1, which offer more possibilities, chain hoists have to be equipped with two separate DC injection brakes, such as the new ROBA®-secustop from mayr® drive technology.

Chain hoists complying with BGV-D8 can only be used to lift loads during installation and dismantling of stage assemblies. During any such work, there must be no one under the load. After lifting, the load must be secured and the chain slackened. This procedure is also known as "dead hanging". This type of chain hoist usually has only one brake, so it is not authorized for holding loads or scenery changes. The motor is only used again during dismantling. This is still the most common use of electric chain hoists in show applications.

To comply with BGV-D8 Plus or BGV-C1 standards, chain hoists have to be equipped with two separate DC injection brakes, amongst other things. The new ROBA®-secustop from mayr® drive technology is a twin brake that fully complies with this requirement. It has been specially developed and tailor-made for the purpose. The series is currently available in three sizes with braking torque ranging from 2 x 4 Nm to 2 x 16 Nm.

Its compact, closed design makes it easy to handle and fit. The working clearance is preset and does not require any subsequent adjustment. This means that malfunctions due to misuse or incorrect adjustment are excluded by construction. ROBA®-secustop brakes feature integrated soundproofing to reduce operating noise. To ensure maximum operating safety and reliability, each brake undergoes full factory inspection after assembly and prior to delivery. ROBA®-secustop brakes are practically maintenance-free. Maintenance work is limited to inspection of the friction linings, which are extremely hardwearing and have a long service life. Safety brakes in the ROBA®-secustop series comply with the guidelines set out in the BGV-D8 Plus and BGV-C1 standards.

Contrary to hoists in compliance with BGV-D8, use of electric chain hoists that meet BGV-D8 Plus requirements is also authorized to hold loads. This avoids the necessity of time-consuming "dead hanging" of loads. However, there must be no one below this type of hoist while it is carrying moving loads or scenery. Nonetheless, people can go underneath the loads once they have been raised and held up.

The strictest safety requirements are met by electric chain hoists that comply with BGV-C1. These are known as point hoists, and they can be used to handle loads while there are people underneath them. This covers installation and dismantling work, and also scenery movement during shows and performances.

mayr® drive technology provides a wide range of brakes for use in stage applications. The new ROBA®-secustop safety brakes for electric chain hoists and lifting gear provide real value for money and make a useful addition to the product range.

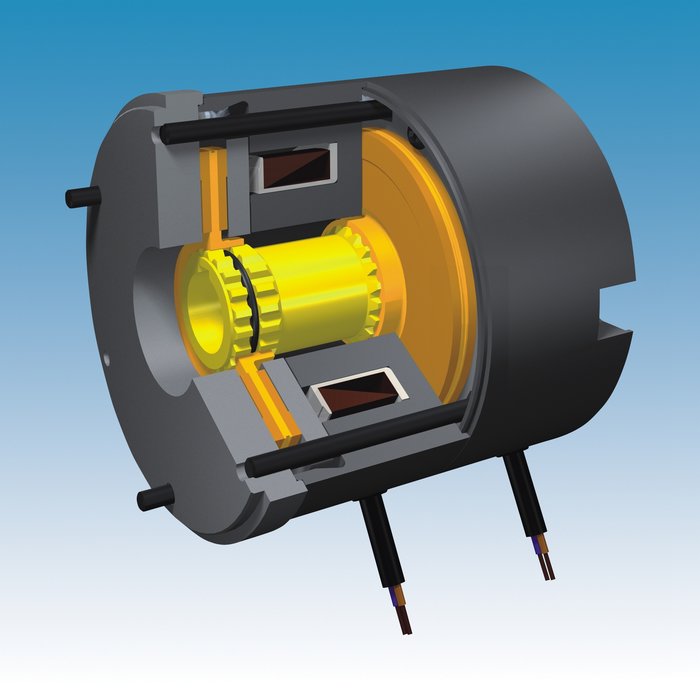

Product illustration (P-6-24-Bild1a.jpg):

ROBA®-secustop: the ideal safety brake for electric chain hoists in show and stage applications.

To comply with BGV-D8 Plus or BGV-C1 standards, chain hoists have to be equipped with two separate DC injection brakes, amongst other things. The new ROBA®-secustop from mayr® drive technology is a twin brake that fully complies with this requirement. It has been specially developed and tailor-made for the purpose. The series is currently available in three sizes with braking torque ranging from 2 x 4 Nm to 2 x 16 Nm.

Its compact, closed design makes it easy to handle and fit. The working clearance is preset and does not require any subsequent adjustment. This means that malfunctions due to misuse or incorrect adjustment are excluded by construction. ROBA®-secustop brakes feature integrated soundproofing to reduce operating noise. To ensure maximum operating safety and reliability, each brake undergoes full factory inspection after assembly and prior to delivery. ROBA®-secustop brakes are practically maintenance-free. Maintenance work is limited to inspection of the friction linings, which are extremely hardwearing and have a long service life. Safety brakes in the ROBA®-secustop series comply with the guidelines set out in the BGV-D8 Plus and BGV-C1 standards.

Contrary to hoists in compliance with BGV-D8, use of electric chain hoists that meet BGV-D8 Plus requirements is also authorized to hold loads. This avoids the necessity of time-consuming "dead hanging" of loads. However, there must be no one below this type of hoist while it is carrying moving loads or scenery. Nonetheless, people can go underneath the loads once they have been raised and held up.

The strictest safety requirements are met by electric chain hoists that comply with BGV-C1. These are known as point hoists, and they can be used to handle loads while there are people underneath them. This covers installation and dismantling work, and also scenery movement during shows and performances.

mayr® drive technology provides a wide range of brakes for use in stage applications. The new ROBA®-secustop safety brakes for electric chain hoists and lifting gear provide real value for money and make a useful addition to the product range.

Product illustration (P-6-24-Bild1a.jpg):

ROBA®-secustop: the ideal safety brake for electric chain hoists in show and stage applications.