www.magazine-industry-usa.com

13

'17

Written on Modified on

Global availability of information in the context of Industry 4.0

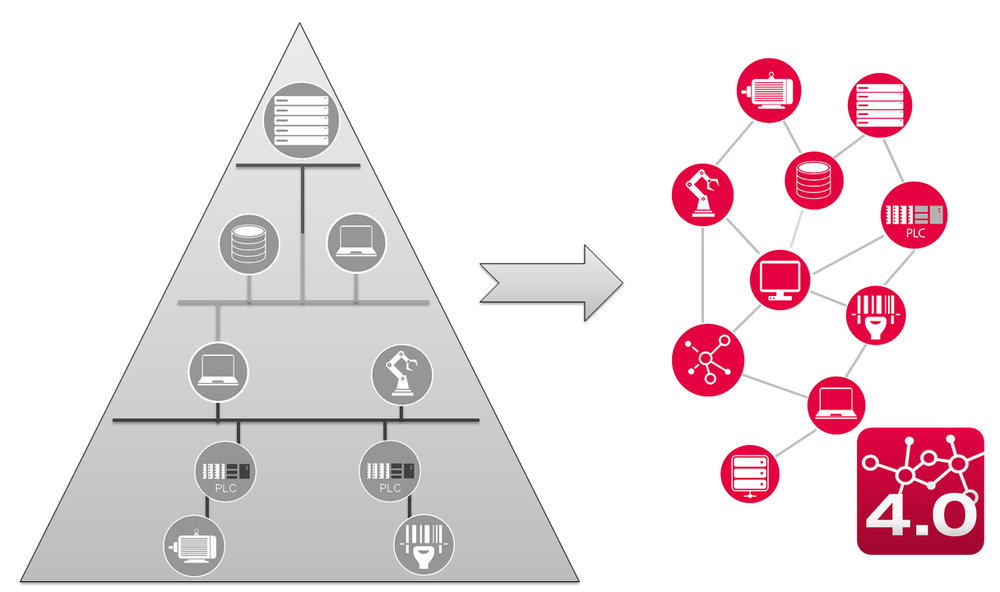

The core business of Industry 4.0 is to make information available from diverse sources and to link this information. Initially the origin of the information should be differentiated. This can be achieved by applying the automation pyramid or the RAMI model 4.0 as orientation: On the one hand this provides information, which has been generated on the field or control level. On the other hand it supplies information, which is managed centrally, e.g. in ERP systems. In this instance it is essential to observe that the information to be linked is not only necessarily available within a company, but has to be exchanged outside corporate boundaries. The added values and business models, which are discussed in the context of Industry 4.0, primarily stem from the fact that information is "collected" from different sources to the field level and is linked to centrally available information, to acquire new knowledge.

The classic flow of data in the automation pyramid takes place from one level to the next – for example from the component level to the control level. This represents a system transition. There are different types of system transitions: On the one hand the technological system transition, for example from one software tool or bus interface to the next. On the other hand, the system transition from one level of the automation pyramid to the other. Undoubtedly the most complex system transition is from one company to another. Each of these system transitions represents a hurdle in classic communication, which generally acts like a data filter, as different physical transfer media and different protocols are normally used in the automation pyramid levels. In the case of company transitions there is the additional factor of mapping to different data models. These hurdles are overcome by using gateways or protocol converters, which often requires great effort and expense.

Therefore the central aim has to be to eliminate these hurdles to make data and information available fast and universally. It is only possible to devote oneself to the actual target – the linking of information from different sources – when data availability is given. These hurdles, however, cannot be eliminated using conventional processes. Instead a central pool is formed, parallel to the existing transfer processes, which can be addressed directly from different sources. The term "Cloud" is currently being used synonymously for this purpose. There are no classic hurdles in the cloud. Different companies can exchange data unobstructed using diverse tenants in the same cloud. The individual companies set up a "private Cloud" in their own tenant as a basis, on which the access permissions are kept completely "private" at first. If it becomes necessary as part of a new business idea to make individual information available to other companies or clouds, it can be exchanged between different tenants. The scalability of the cloud capacities allows for the recording of data, which is as yet unknown to the user and could give rise to additional knowledge or generate business cases in the future as applicable.

In American English the term "Internet of Things" (IoT or IIoT) is used instead of Industry 4.0. This term was intentionally associated with the developments of the "World Wide Web" around the turn of the millennium twenty years ago. The developments in this area were very similar. The sudden availability of different data in a common data space has lead to new networking and eventually to new business models. From our point of view, we can outline a very similar course of development for Industry 4.0 and IoT/IIoT. Firstly, the primary aim has to be making data available from different sources. The networking of this data is the next step and finally new business models emerge. Metaphorically speaking, we are currently constructing a highway for transporting goods at a later stage, to which we can then attach business cases. At the moment no one knows exactly where this highway will lead. This can be illustrated through the development of industrial communication relations: In the past, point-to-point connections between the control unit and the respective device - sensor or actuator - have dominated industrial automation. Today the master/slave communication model dominates between the levels of the automation pyramid. This means that a control unit typically operates several end devices (fieldbus installation) through one cable. Thus, a transition to a netlike communication architecture is created, which we already know from the IT sector. This enables data transfer between all levels in arbitrary directions. It is essential for the networking and assessment of the data that the data is up-to-date and has a specific, for example geographical, reference. This development again models itself on the classic IT systems. Example of "Google Maps": Data on traffic congestion is taken directly from the vehicles, linked to geographical data and is made available for evaluation within a few seconds.

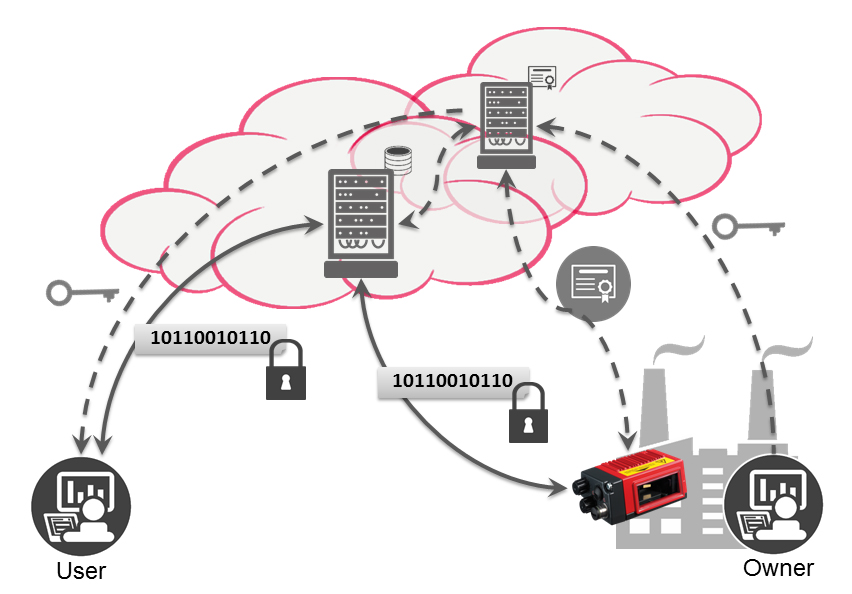

For this reason we, the sensor people at Leuze electronic, have committed ourselves to the subject of data availability and for the first time have brought data directly from the sensor into the cloud, across all systems. This involves the integration of an OPC UA server in our sensor and docking onto the Microsoft Azure Cloud with the publisher-subscriber model. We have extended this transition by the IoT Proxy from Microsoft to enable data transfer universally in all directions. The proxy now makes it possible to analogically operate client-server communication to local shop floor concepts. The major difference of these solutions is that this communication and consequently the data is available globally and not just locally. Therefore, the data can also be networked globally across systems and company borders for interpretation and evaluation purposes.

This global availability immediately raises the question of data integrity. It is an inevitably accepted prerequisite that data integrity must be ensured on communication channels and in globally available systems. OPC UA is tested in line with the federal institute for security and information technology and offers all four generally stipulated safety features for secure communication: Authentication, authorization, verification and encryption. In this way tested methods and procedures from the world of information technology (IT) are transferred into the world of automation technology (OT – Operations Technology). This can be subsumed under the heading "IT2OT" (or "ITgoesOT"). This raises questions about global authorization procedures: Future authentication will take place using certificates. In the future, sensors from Leuze electronic will therefore be equipped with a unique safety certificate in addition to the identification data to date such as their serial number.

To make data in the cloud available and easy to use, without having to use big data and neural network technology on the data in the cloud, it is essential that the data is clearly structured before being sent (for example from a sensor) and has been transformed into information in place of raw data. Ideally the aim is to provide information from related data sources in a standardized structure. Different attempts and approaches have already been undertaken in this direction. Consequently there will be a specification of the management shell from ZVEI with the OPC UA description model. An application-specific companion standard from the "Advancing identification matters user organization" has also been specifically defined for sensors in the auto ID sector (for example bar code scanner). The use of application-specific device descriptions and profiles standardizes the interpretation of information. Leuze electronic will implement this standard in its Ident products. Thus, seamless integration of information from Leuze bar code readers into the I4.0 management shell is possible. Seamless means that the information can be transferred from the sensors via OPC UA and can be applied in the management shell data model without additional transformation.

To consistently structure the availability of information, detection and addressing of data sources has to be made possible across all system borders from the cloud. This does not entail making unprotected access possible but rather is an installation aid. It is not practicable to manually publicize a large number of edge devices (for example sensors and actuators) to a global cloud system, or to register them in the cloud system. Instead technological mechanisms are required, which make it possible for the cloud system to autonomously identify edge devices that are centrally assigned to it. These mechanisms are called global discovery functionalities. There are two different mechanisms, which are integral parts of the OPC UA standard: Local discovery mechanisms (Local Discovery Server) on the one hand, and on the other hand global discovery mechanisms (Global Directory Server). These mechanisms require an extensive certificate exchange (Trust List Type) to safeguard access. Sensors from Leuze electronic are – corresponding to its client promise "Smarter Usability" – available with secure access in all forms of the discovery mechanisms.

As outlined at the beginning, one of the core points of Industry 4.0 is the holistic information provision in the life cycle of an asset. This means that different information should be bundled in so-called management shells and be made available to the different users quickly and transparently. In this system approach the ideas of augmented reality technology fit in seamlessly. With the help of data glasses this technology enriches the actual visible environment with virtual information in the user's field of vision. This technology is especially suitable for Industry 4.0 with the definition of extensive asset descriptions, as the diverse information can be made visible directly at the object's actual place of use, without physically intervening in the system. A decisive advantage is the visualization of the features and characteristics, which were to date only available in graphics in manuals and web portals and are now visibly on display in the field of vision at the appropriate point in the actual space. This applies in particular to optical sensors, with a reading beam or reading field that is not visible to the user. The user no longer needs to avail of cumbersome transfer services. Leuze electronic shows the benefit of usability with the data glasses from Microsoft. Taking the example of two bar code readers which are installed on a conveyor belt and conduct active readings, their different information such as current status and device description appears in the user's field of vision, when looking at the device.

Author

Head of Competence Center Software

Leuze electronic GmbH + Co. KG

www.leuze.com