www.magazine-industry-usa.com

05

'08

Written on Modified on

Heat pump cuts energy costs by up to 50%

FAIVELEY HEAT PUMP SYSTEM - Faiveley Transport’s new Heat Pump is a major HVAC innovation because it can cut energy consumption by up to 50%. In its target market, the rail industry, this equates to around 1500 USD/year for each carriage.

For moderate heating and cooling needs, heat pumps offer an energy-efficient alternative to furnaces and air conditioners. Like a refrigerator, heat pumps use electricity to move heat from a cool space into a warm space - making the cool space cooler and the warm space warmer.

In cold weather, heat pumps move heat from the cool outdoors into the warm train; in warm weather, they transfer heat from the train to the outdoors. Because they move heat - rather than generate heat - the heat pumps can provide up to four times the amount of energy they consume.

This kind of system is well-proven for heating and cooling buildings, but Faiveley has extended the concept to railway carriages.

In cold weather, heat pumps move heat from the cool outdoors into the warm train; in warm weather, they transfer heat from the train to the outdoors. Because they move heat - rather than generate heat - the heat pumps can provide up to four times the amount of energy they consume.

This kind of system is well-proven for heating and cooling buildings, but Faiveley has extended the concept to railway carriages.

Easy-to-implement

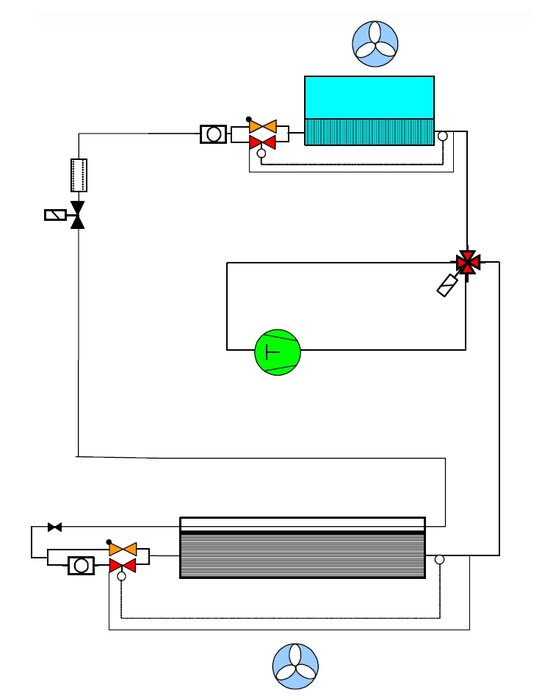

This HVAC system consists of a compressor (existing or not) and two coils made of copper tubing - one inside and one outside. The system is reversible, so can provide either heating or cooling in a single unit. In heating mode, liquid refrigerant in the outside coils extracts heat from the air and evaporates into a gas. The inner coils then release heat from the refrigerant as it condenses back into a liquid. A reversing valve near the compressor changes the direction of the refrigerant flow.

Short Return on investment

Faiveley Transport’s heat pump offers higher energy efficiency in heating mode - from 2 to 4 according to ambient temperature - enabling reduction of CO2 emissions. An electrical heater is still needed for very low ambient temperatures. Global power consumption can be reduced by 50%. The cost reduction potential is more 1000 USD per coach/year offering a payback time of three to four years.

Railway proven solution

Three heat pumps units have been tested on the German rail network since January 2007, showing a global energy cost reduction of 40%.

This HVAC system consists of a compressor (existing or not) and two coils made of copper tubing - one inside and one outside. The system is reversible, so can provide either heating or cooling in a single unit. In heating mode, liquid refrigerant in the outside coils extracts heat from the air and evaporates into a gas. The inner coils then release heat from the refrigerant as it condenses back into a liquid. A reversing valve near the compressor changes the direction of the refrigerant flow.

Short Return on investment

Faiveley Transport’s heat pump offers higher energy efficiency in heating mode - from 2 to 4 according to ambient temperature - enabling reduction of CO2 emissions. An electrical heater is still needed for very low ambient temperatures. Global power consumption can be reduced by 50%. The cost reduction potential is more 1000 USD per coach/year offering a payback time of three to four years.

Railway proven solution

Three heat pumps units have been tested on the German rail network since January 2007, showing a global energy cost reduction of 40%.

Faiveley Transport’s Heat pump functional diagram