www.magazine-industry-usa.com

19

'25

Written on Modified on

Onshoring Silicon Carbide Manufacturing for U.S. Energy Systems

General Atomics Electromagnetic Systems expands domestic production of silicon carbide for advanced nuclear and energy applications.

www.ga.com

General Atomics Electromagnetic Systems (GA-EMS) has developed and scaled new manufacturing methods for silicon carbide (SiC) ceramic matrix composites in the United States, addressing longstanding cost, supply chain, and performance barriers associated with this high-performance material. This initiative directly responds to industry and government needs for a domestically sourced solution in critical energy and aerospace applications.

Domestic Manufacturing of Silicon Carbide Materials

Silicon carbide is valued for its exceptional strength, low weight, thermal stability, and resilience in extreme environments, making it well-suited for use in nuclear energy systems, gas turbines, and aerospace platforms. Traditionally, the widespread adoption of SiC has been constrained by high material costs and dependence on foreign sources. GA-EMS’s new processes produce high-quality SiC fiber and related composites more rapidly and at lower cost, establishing a domestic supply chain that enhances reliability for advanced energy technologies.

The upgraded production approach includes a continuous SiC fiber process capable of reducing domestic production costs by approximately 60 percent. Alongside this, the company’s use of automated fiber placement and hybrid densification techniques yields dense, high-purity SiC composites with significantly faster throughput and reduced energy consumption compared with conventional methods. These efficiencies are reported to accelerate fabrication by 70 percent while cutting energy usage by 80 percent relative to traditional chemical vapor infiltration processes.

Application in Nuclear Energy and Beyond

The enhanced accessibility of SiC materials supports expanded use in demanding applications where performance under extreme stress, heat, and radiation is essential. In the nuclear sector, SiC composite materials are advancing as a critical technology for improved fuel cladding and other reactor components, offering thermal performance and durability beyond that of existing materials. GA-EMS’s silicon carbide innovations align with Department of Energy (DOE) priorities to strengthen U.S. energy infrastructure and reduce reliance on foreign material sources.

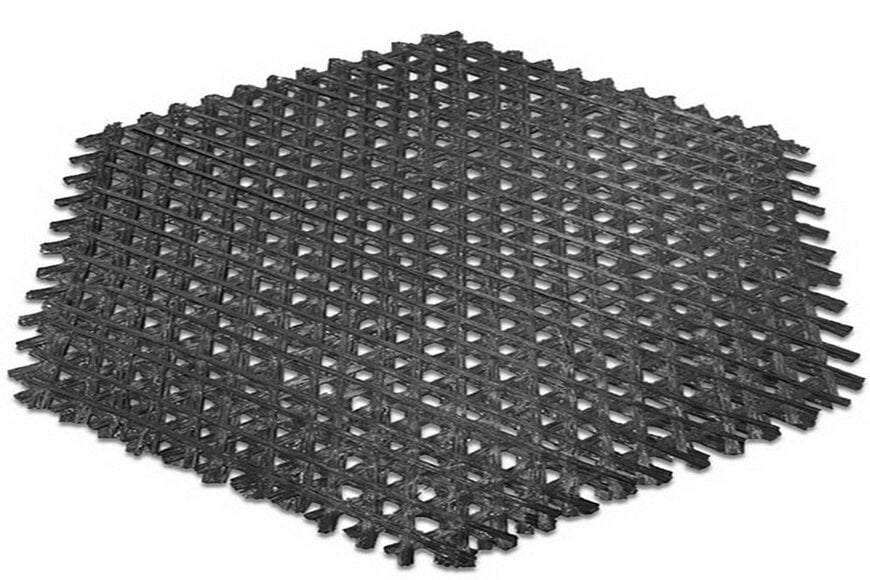

GA-EMS expands access and industrial usage of SiC to deliver a critical material for advanced energy applications.

Improved Performance and Industrial Impact

By reducing costs and energy inputs for SiC production, GA-EMS is positioned to enable broader deployment of advanced energy systems and support supply chain resilience. The development of scalable, affordable silicon carbide manufacturing in the United States differentiates GA-EMS from competitors that have historically depended on imported raw materials or less efficient production methods. This domestic capability may accelerate adoption of SiC composites across energy, aerospace, and defense sectors, where high-temperature performance and material reliability are increasingly critical.

Funding and Strategic Alignment

The work at GA-EMS is supported by programs funded through the DOE’s Advanced Materials and Manufacturing Technologies Office, reflecting federal priorities to advance domestic manufacturing of critical materials. By enhancing cost-effectiveness and scalability, the company’s silicon carbide initiatives contribute to U.S. industrial competitiveness in advanced materials while supporting long-term energy and aerospace innovation.

The onshoring of silicon carbide production by General Atomics Electromagnetic Systems represents a significant advancement in U.S. materials manufacturing for high-performance energy applications. Through scalable processes that lower cost and increase production efficiency, GA-EMS strengthens domestic supply chains and supports broader deployment of critical technologies in nuclear energy, aerospace, and other demanding sectors.

www.ga.com