www.magazine-industry-usa.com

09

'25

Written on Modified on

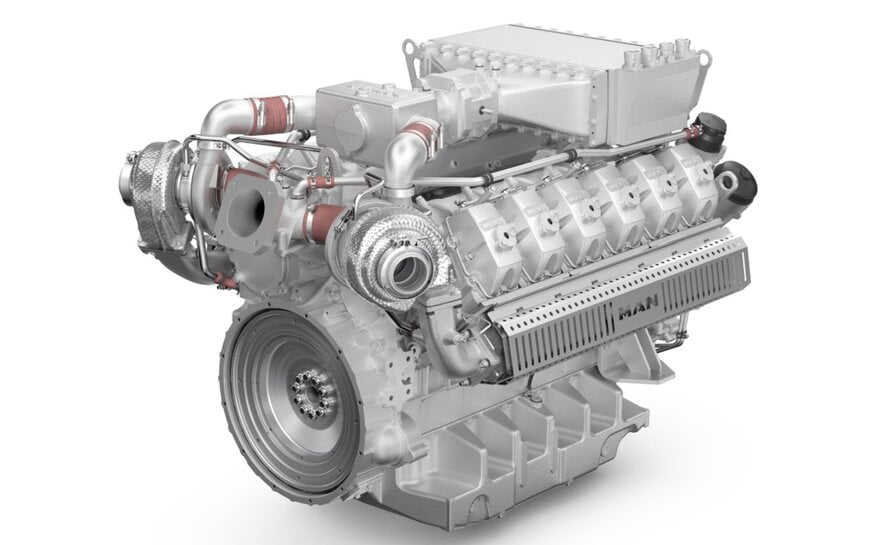

MAN Engines Introduces Updated E32 Gas Engine Series

The redesigned natural gas and biogas engines gain a new turbocharger, improved efficiency and global emission compliance ahead of their 2026 market rollout.

www.man.eu

Natural gas and biogas power generation, combined heat and power systems and other stationary energy applications increasingly require engines that meet stricter global efficiency and emission standards. In this context, MAN Engines has updated its established E32 gas engine series to align with the operational and regulatory demands of future international markets.

Since the series entered the market in 2012, more than 10,000 units have been installed worldwide, demonstrating a consistent performance record. The current product revision focuses on the two main variants, the E3262 LE202 for natural gas and the E3262 LE212 for biogas, both of which receive significant turbocharger redesigns.

Turbocharger Revision for Efficiency and Durability

The upgraded turbocharger now integrates a dry turbine housing with insulation, removing the need for external water-bearing pipes. This technical change reduces the number of potential leakage points and avoids thermal hotspots in low-coolant situations—both validated engineering benefits that improve reliability in stationary power environments. The addition of thrust and plain bearings made from a corrosion-resistant bronze alloy extends service life, particularly in biogas engine operation, where gas quality can vary.

Efficiency gains are especially noticeable at the widely adopted nitrogen oxide limit of 250 mg/Nm³ NOₓ, which is a regulatory benchmark in many countries. The updated turbocharger design supports compliance with this threshold without compromising engine output.

Performance Stability Under Variable Conditions

A higher pressure reserve via the throttle valve provides a larger power buffer. This contributes to stable output at sites with elevated exhaust gas back pressure or high-altitude installations—a documented issue for large gas engines that rely on optimal air-fuel ratios.

Proven Platform and Global Compatibility

The modernized E3262 continues to rely on MAN’s established V12 architecture. This platform is already used globally as the D2862 diesel engine in marine applications and as the E3262 gas engine for stationary heat and power systems, with displacements of 24.2 and 25.8 liters, respectively. Its long service record supports its classification as one of the most field-proven engines in this segment.

Both turbocharged and naturally aspirated versions remain available, allowing operators to match the engine configuration to site-specific requirements—whether electrical-output-driven or heat-driven. With options for 50 Hz and 60 Hz grids, the engine remains suitable for worldwide deployment.

Flexible Emission Compliance

The engine meets 250 mg/Nm³ NOₓ emission requirements internally and can also be paired with an external SCR system to meet stricter thresholds of 100 mg/Nm³ NOₓ. This approach gives operators flexibility during permitting and ensures compatibility with regions enforcing tighter air-quality limits.

www.mantruckandbus.com