www.magazine-industry-usa.com

10

'25

Written on Modified on

Schaeffler wins major order for the North American market

Schaeffler secures a major North American market win with a new dual inverter for a U.S. pickup truck platform, with a volume of nearly one million units.

www.schaeffler.com

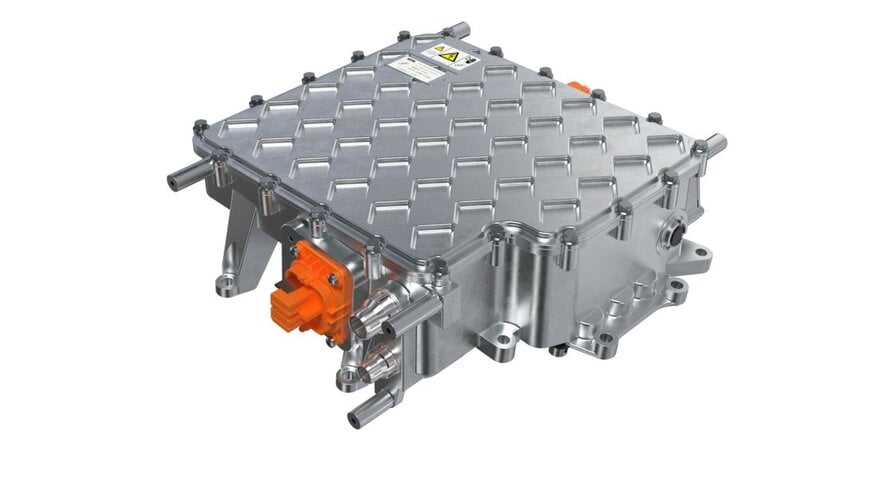

Schaeffler has announced a milestone in the field of powertrain electrification: A vehicle manufacturer has ordered a dual inverter from Schaeffler for the North American market, which controls the electric drive for auxiliary units and serves as a traction inverter to power an electric drive motor with an output of over 200 kW. The dual inverter is intended for electrified pickup truck models for the North American market, where this vehicle type is particularly popular. This order means that Schaeffler is now collaborating with another major OEM in the field of hybridization. The dual inverter contributes to the all-electric range of plug-in hybrid vehicles (PHEVs), partly because it utilizes highly efficient silicon carbide chips from Schaeffler’s strategic partner onsemi. According to current planning, production of the inverter at Schaeffler’s plant is estimated to begin by the end of 2027.

“This order recognizes the capabilities of our inverter experts in Deer Park, who were able to realize this highly specialized dual inverter with demanding requirements in a short period of time. We are proud to deliver this product for use in plug-in hybrid pickup trucks,” said Thomas Stierle, CEO E-Mobility at Schaeffler.

The challenges in developing the dual inverter included demanding specifications from the OEM regarding installation space, performance, and inverter efficiency. The requirements for the two inverter units differ significantly: The starter-generator is integrated into the belt drive of the internal combustion engine. Conventional silicon insulated gate bipolar transistors (IGBTs) are used in the inverter to control this small electric motor. The required power density and efficiency for the compact traction inverter for the electric drive motor, on the other hand, are achieved by Schaeffler using EliteSiC silicon carbide (SiC) MOSFETs from onsemi. This SiC technology enables very high switching speeds in the inverter with minimal electrical losses, which in turn allows for greater electric driving ranges.

www.schaeffler.com

“This order recognizes the capabilities of our inverter experts in Deer Park, who were able to realize this highly specialized dual inverter with demanding requirements in a short period of time. We are proud to deliver this product for use in plug-in hybrid pickup trucks,” said Thomas Stierle, CEO E-Mobility at Schaeffler.

The challenges in developing the dual inverter included demanding specifications from the OEM regarding installation space, performance, and inverter efficiency. The requirements for the two inverter units differ significantly: The starter-generator is integrated into the belt drive of the internal combustion engine. Conventional silicon insulated gate bipolar transistors (IGBTs) are used in the inverter to control this small electric motor. The required power density and efficiency for the compact traction inverter for the electric drive motor, on the other hand, are achieved by Schaeffler using EliteSiC silicon carbide (SiC) MOSFETs from onsemi. This SiC technology enables very high switching speeds in the inverter with minimal electrical losses, which in turn allows for greater electric driving ranges.

www.schaeffler.com