www.magazine-industry-usa.com

16

'17

Written on Modified on

Wickless Pulsating Heatpipe Systems

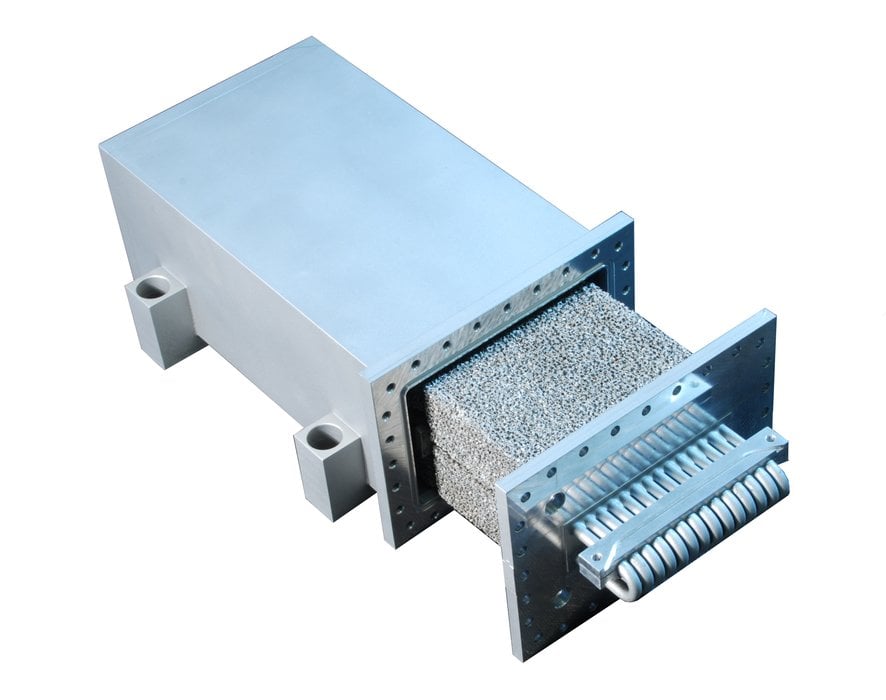

REXUS Pulsating Heatpipe System developed by Aavid Thermalloy’s Italian Design Center in conjunction with the European Space Agency has been launched from the Esrange Space Center in Kiruna, North Sweden. It’s one of two prototypes manufactured for the INWIP Project (Innovative Wickless Heat Pipe Systems) in order to study the behaviour of a Pulsating Heatpipe System in micro-gravity conditions.

The second prototype designed and manufactured by AAVID for the INWIP Project is the ISS: a Pulsating Heatpipe System connected to 8 Peltier cells. The heat carried by vapour bullets flows inside the aluminium tube warming one side of the Peltier cells while a liquid cold plate cools the other side. The cooling system will be installed on Zero Gravity Flight, where the plane will run along 32 parables. In correspondence to each peak of each parable, the force of gravity will be balanced by the vertical traction, creating a transient state of 22 seconds of micro-gravity. During this time, the behaviour of the pulsating heatpipe will be observed.

A further aim of the research is the preparation of systematic experimentation on the Thermal Platform1 (TP1) onboard the International Space Station, investigating the performances of cooling systems with ordinary and innovative working fluids.

For further information on this exciting project or for assistance with your more down-to-earth industrial projects, contact Aavid’s Design Center at Bologna, Italy : This email address is being protected from spambots. You need JavaScript enabled to view it.