www.magazine-industry-usa.com

01

'25

Written on Modified on

Schmalz Launches FA-X and FA-M Vacuum Area Gripping Systems

Schmalz introduces FA-X with integrated vacuum generator and FA-M for external sources, cutting energy use by 80% while enabling flexible, reliable handling of diverse materials.

www.schmalz.com

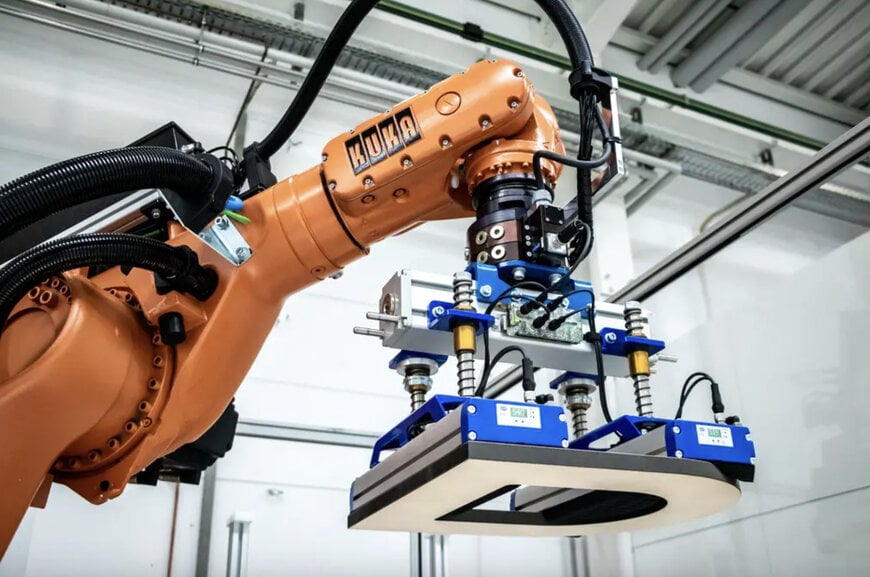

The vacuum area gripping systems FA-X / FA-M handle different workpieces precisely and very energy-efficiently.

If you want to palletize, depalletize, pick or sort automatically, you need to handle different workpieces safely and efficiently. This is a real challenge in logistics, wood processing and packaging. With the vacuum area gripping systems FA-X and FA-M, Schmalz presents a solution that is both flexible and energy-efficient. Applications use them to move workpieces made of wood, sheet metal, glass and plastics. These can also be porous, flexible and irregularly shaped. Thanks to their low weight and minimal interfering contours, the end effectors are ideal for robot arms. The surface gripping systems are optimized for sustainable processes and versatile material handling and offer maximum efficiency with minimum consumption.

Intelligent technology for sustainable processes

The surface gripping systems have a vacuum booster that ensures very short cycles. The FA-X variant has an integrated vacuum generator, while the FA-M model is designed for external vacuum sources. They are available with either suction cups or a flexible sealing foam with adhesive film. Both area gripping systems offer variants for different requirements: from the basic version to the intelligent version with LED display, energy-saving function and integrated sensors. The smart version shows data on energy consumption and system status directly on the display, but also sends it to a smartphone via IO-Link or an app. This allows companies to keep an eye on their processes at all times and optimize maintenance intervals in a targeted manner.

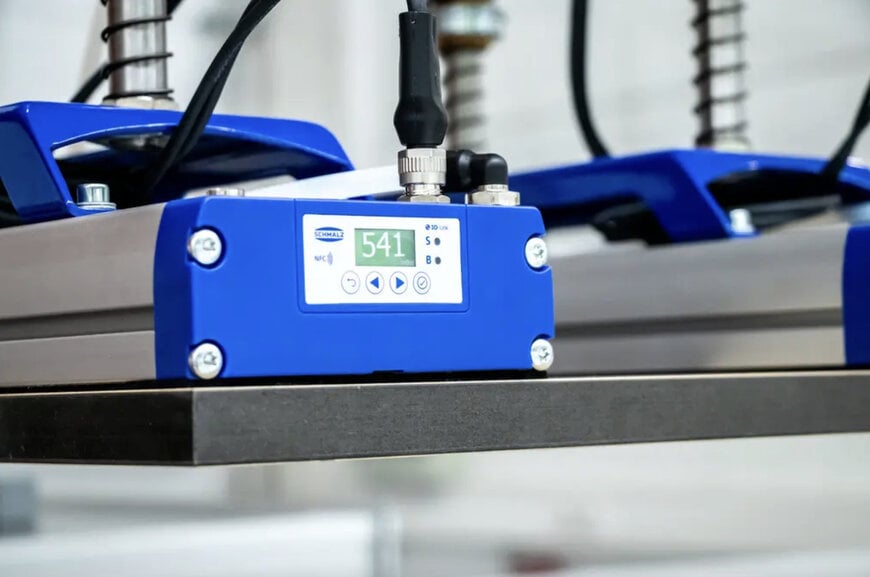

The optional LED display informs the user about energy and condition monitoring, for example.

Save energy, lower costs

The energy-saving function reduces energy consumption by up to 80 percent because individual nozzle lines can be switched in a targeted manner. This not only reduces operating costs, but also saves resources. Downtimes cost money. That's why Schmalz focuses on simple maintenance: workers can replace the sealing foam in just a few minutes thanks to the quick-change adhesive film. The ejector is easily accessible. As an optional extra, an integrated sensor system in the sealing foam detects whether the workpiece has been gripped correctly - this increases process reliability and minimizes waste.

With the vacuum area gripping systems FA-X / FA-M, Schmalz offers a solution that automates processes, lowers operating costs and makes production fit for the future. Customers benefit from flexible, maintenance-friendly and intelligent technology that can be seamlessly integrated into existing systems.

www.schmalz.com

If you want to palletize, depalletize, pick or sort automatically, you need to handle different workpieces safely and efficiently. This is a real challenge in logistics, wood processing and packaging. With the vacuum area gripping systems FA-X and FA-M, Schmalz presents a solution that is both flexible and energy-efficient. Applications use them to move workpieces made of wood, sheet metal, glass and plastics. These can also be porous, flexible and irregularly shaped. Thanks to their low weight and minimal interfering contours, the end effectors are ideal for robot arms. The surface gripping systems are optimized for sustainable processes and versatile material handling and offer maximum efficiency with minimum consumption.

Intelligent technology for sustainable processes

The surface gripping systems have a vacuum booster that ensures very short cycles. The FA-X variant has an integrated vacuum generator, while the FA-M model is designed for external vacuum sources. They are available with either suction cups or a flexible sealing foam with adhesive film. Both area gripping systems offer variants for different requirements: from the basic version to the intelligent version with LED display, energy-saving function and integrated sensors. The smart version shows data on energy consumption and system status directly on the display, but also sends it to a smartphone via IO-Link or an app. This allows companies to keep an eye on their processes at all times and optimize maintenance intervals in a targeted manner.

The optional LED display informs the user about energy and condition monitoring, for example.

Save energy, lower costs

The energy-saving function reduces energy consumption by up to 80 percent because individual nozzle lines can be switched in a targeted manner. This not only reduces operating costs, but also saves resources. Downtimes cost money. That's why Schmalz focuses on simple maintenance: workers can replace the sealing foam in just a few minutes thanks to the quick-change adhesive film. The ejector is easily accessible. As an optional extra, an integrated sensor system in the sealing foam detects whether the workpiece has been gripped correctly - this increases process reliability and minimizes waste.

With the vacuum area gripping systems FA-X / FA-M, Schmalz offers a solution that automates processes, lowers operating costs and makes production fit for the future. Customers benefit from flexible, maintenance-friendly and intelligent technology that can be seamlessly integrated into existing systems.

www.schmalz.com