NORD to Showcase Reliable, Scalable Packaging Solutions at PACK EXPO

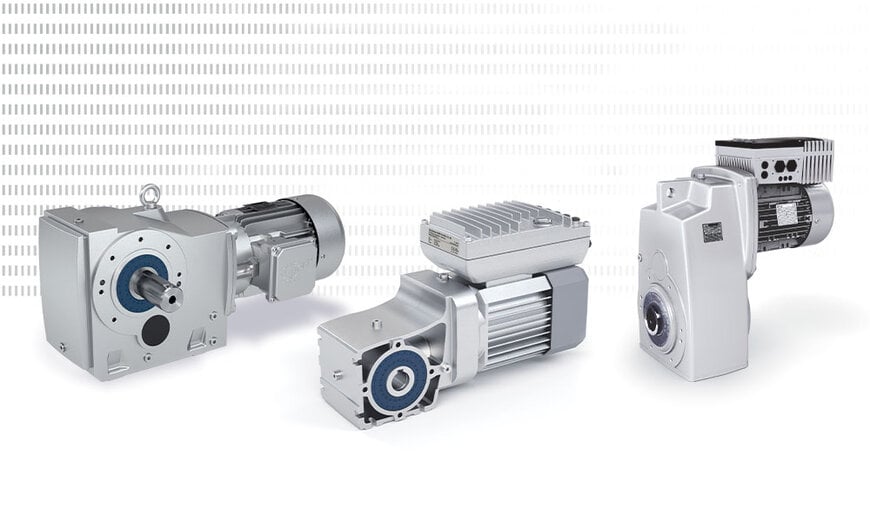

The portfolio of NORD gear units, electric motors, and electronic control products form complete, modular solutions that handle the packaging needs of today and tomorrow.

www.nord.com

NORD’s packaging solutions focus on reliability, versatility, and efficiency. With over 20,000,000 standard configurations to choose from, NORD delivers precisely configured drive systems for end-of-line packaging applications, such as pick-and-place, labeling, filling, sealing, wrapping, strapping, and palletizing machines. The comprehensive product portfolio also includes a wide range of options for general conveyance between packaging steps, with optional safety features like soft start, brake ramps, and STO functions to protect workers, equipment, and products.

NORD will be exhibiting at PACK EXPO Booth SU-20098, near the front of South Upper Hall. Stop by to see these featured products and more:

NORDBLOC.1 Helical Gear Units

Performance optimized NORDBLOC.1 gear units deliver high efficiency with low operating costs. Made from high strength, lightweight aluminum alloy, these units are ideal for packaging systems as they reliably handle high axial and radial loads and provide a long service life with minimal maintenance. NORDBLOC.1 gear units are extremely versatile, with helical inline, helical bevel, single-stage helical, and two-stage helical bevel gear options available. They also offer various shaft options, mounting options, and application-specific versions available for precise system adaptation.

UNIVERSAL SI/SMI Worm Gear Units

Thanks to their modular design and high power density, NORD UNIVSERAL SI/SMI worm gear units can be quickly and easily adapted to a wide variety of applications. Reinforced bearings enable the worm drives to absorb large axial forces from pouch sorter applications while their compact design optimizes space utilization. While SI gear units have an open housing for better heat dissipation, SMI gear units are available as a smooth surface for easy cleaning in hygienic areas. Both series also offer various configuration options including hollow or solid shafts, shaft-, flange-, or foot-mounted versions, and NEMA, IEC, or direct motor mounting options.

IE5+ Synchronous Motors – The Next Level of Energy Efficiency

Compact and highly efficient, NORD IE5+ synchronous motors achieve significant energy savings, reduce operating costs, and provide a fast ROI. The extremely efficient operation is possible thanks to the use of permanent magnets which eliminate the need for an external energy supply to generate the magnetic field, additionally enabling high power density and a higher maximum achievable torque. Unlike asynchronous motors, IE5+ motors deliver constant torque and efficiency over a wide speed range, even during partial load operation and at low speeds, allowing for system variants to be minimized. The motors additionally are available as a smooth surface design for hygienic environments (TENV) and a finned version for optimized heat dissipation in heavy traffic systems (TEFC).

NORDAC ON/ON+ Variable Frequency Drives – Strong Focus, Optimum Function

Decentralized NORDAC ON/ON+ variable frequency drives were designed to satisfy the demands of horizontal conveyor technology. NORDAC ON drives are complemental to IE3 asynchronous motors while NORDAC ON+ drives are optimized for combination with high-efficiency IE5+ synchronous motors. With an integrated multi-protocol Ethernet interface, full PLC functionality for drive-related functions, and parameterization via plug-in control module, these VFDs offer a compact, economic solution for IIoT environments. They also feature a plug-and-play design for simple installation and maintenance, functional safety options, and POSICON integrated positioning mode with high precision control for smooth, precise operation of packaging systems.

DuoDrive Integrated Gear Unit and Motor – Ultra-modern Efficiency

DuoDrive combines a single-stage helical gear unit with a high-efficiency IE5+ synchronous motor in one compact, space-saving housing design. The smooth surface enables easy cleaning in wash-down and other environments that require the highest hygiene standards. Along with an extremely high system efficiency thanks to permanent magnet synchronous motor (PMSM) technology, DuoDrive also provides high power density, quiet operation, and a simple plug-and-play design for quick commissioning and easy maintenance. Compared to other drive systems, the complete solution results in a reduced Total Cost of Ownership (TCO) and a fast return on investment.

NORDAC PRO SK 500P Variable Frequency Drives

NORDAC PRO SK 500P variable frequency drives are a control cabinet solution built for scalability. Five case sizes are available with various extension module options, ensuring the electronic control device meets specific application requirements. The SK 550P version has an integrated multi-protocol Ethernet interface for efficient connection to Ethernet-based control systems and easy operation of entire systems. Integrated POSICON positioning ensures conveyors are precisely controlled and product does not block ramps or get backed up, causing delays and unplanned downtimes. These drives promote dynamic, intelligent operation of Industry 4.0 environments.

LogiDrive – the Complete Drive Solution

The complete LogiDrive® solution provides a standardized, service-friendly drive system that is ideal for high-volume packaging systems. The modular system combines different NORD products into one drive solution configured to industry standards and specific application requirements. For every area, there are advanced versions with IE5+ synchronous motors and basic versions with IE3 asynchronous motors the primarily focus on cost efficiency. Versions with IE5+ synchronous motors achieve their full savings potential in partial load and partial speed ranges, additionally enabling reduced system variants and a lower TCO.

Condition Monitoring for Predictive Maintenance

NORD’s condition monitoring technology for predictive maintenance systems are integrated directly into their variable frequency drives and focus on status-based maintenance rather than time-based maintenance. This approach effectively reduces unplanned downtimes, optimizes overall system efficiency, and provides longer service life for components and machines. The solution also fits seamlessly into IIoT environments, recording drive and status data either periodically or continuously to derive important information from the data analysis. Threshold values and general status information can further be communicated externally via normal Industrial Ethernet dialects.

Learn more about NORD’s reliable, high-efficiency packaging solutions and discuss your next project by visiting them at PACK EXPO Booth SU-29008. www.nord.com