www.magazine-industry-usa.com

12

'16

Written on Modified on

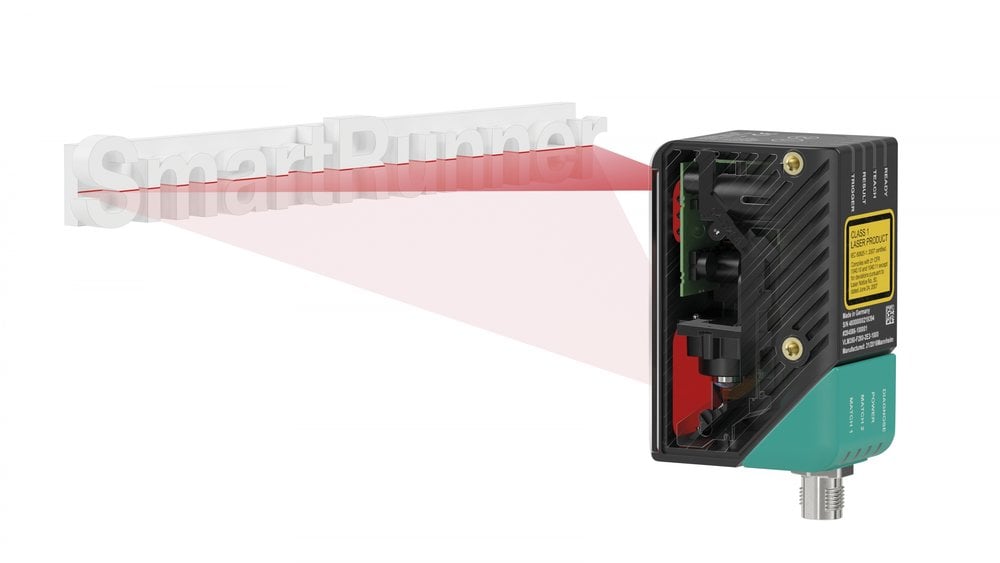

Light Section and Vision Sensors Perfectly Combined in One Device Ready-to-use solutions for comparison and surveillance tasks

The light section sensors from the SmartRunner range uniquely combine a high-precision light section sensor and vision sensor into one compact device.

These ready-to-use, plug&play devices from Pepperl+Fuchs are optimized at the factory for a specific field of work. Unlike conventional "general purpose" devices, commissioning and parameterization is extremely simple to carry out using teach-in or via data matrix control codes, and does not require trained and qualified personnel.

Thanks to powerful LED lighting, SmartRunner devices are capable of capturing images for the visual documentation of errors, process conditions and quality attributes. The integrated data matrix decoder allows the user to parameterize the sensor simply via data matrix control codes - without using a PC. The light section sensors supply the detection result as a good or bad signal to the switching outputs, which can be processed using any control panel.

The first representatives of the device family to be available are the SmartRunner "Matcher" and the SmartRunner "Detector". The Matcher is optimized to recognize a previously taught-in reference contour. Typical tasks include checking the position and accuracy of objects with high precision, to verify whether the robot can grasp body components, for example.

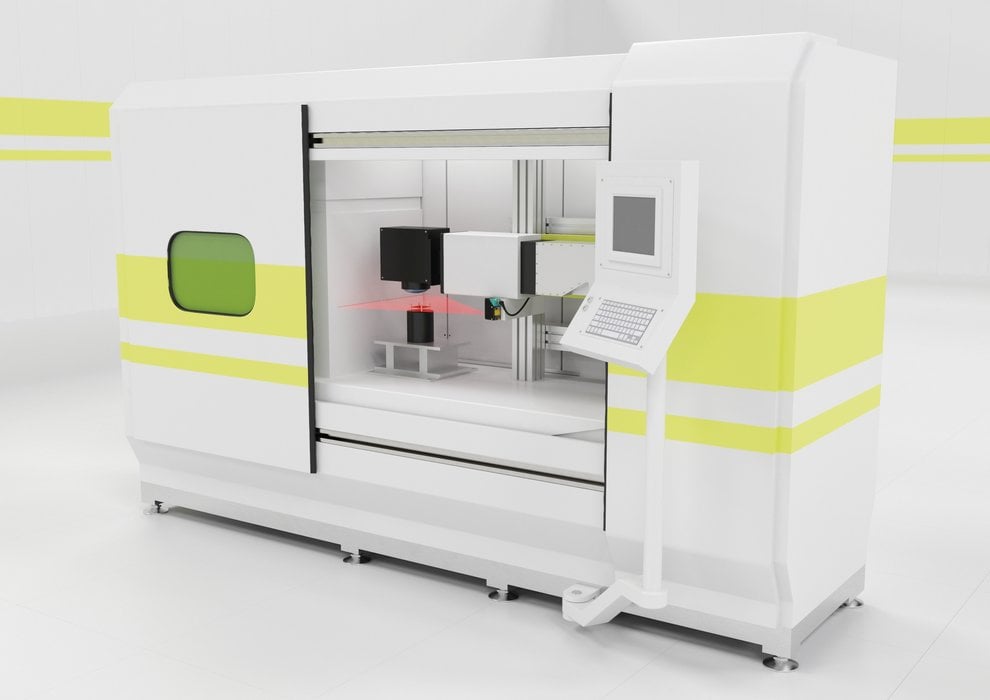

In contrast, the SmartRunner Detector monitors the taught-in scene for the entry of foreign bodies that pose a danger to sensitive machine parts, such as expensive lenses and precision tools. It detects objects with a size range of up to 1 mm with high accuracy, using a trapezoidal measuring range that is 350 mm wide and 700 mm deep.

The SmartRunner has numerous areas of use, such as in the automotive industry and in many areas of plant and mechanical engineering.

Picture 2: Machinery observation by laser light section technology. The SmartRunner observes the sensitive machine parts, recognizes forbidden overlap and stops the movement of the machine if needed.