www.magazine-industry-usa.com

25

'25

Written on Modified on

Dassault Systèmes and KUKA Partner to Boost Robotics and Automation Efficiency for Manufacturers

Dassault Systèmes joins KUKA’s mosaixx digital ecosystem to provide customers with an easy way to purchase and use its 3DEXPERIENCE platform.

www.3ds.com

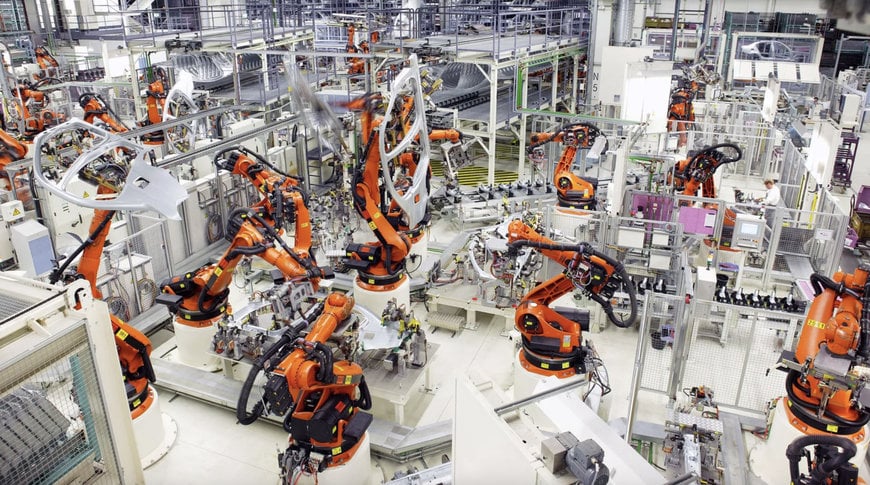

Dassault Systèmes announced its partnership with the global industrial automation and robotics company KUKA to provide manufacturing industries with comprehensive solutions that meet growing demands in robotics and automation.

Under the terms of the agreement, Dassault Systèmes is joining mosaixx, KUKA’s digital ecosystem for industrial software solutions, offering KUKA customers an easy way to purchase and use Dassault Systèmes’ 3DEXPERIENCE platform and applications. By expanding customer access to virtual twin technology and enhanced collaboration capabilities, Dassault Systèmes and KUKA with its newly founded segment KUKA Digital can unlock opportunities for companies to drive the development of more efficient and adaptable solutions that transform their operations.

The global market value of industrial robot installations is estimated at $16.5 billion, driven by AI, energy efficiency and other trends. With more than four million industrial robots operating in factories worldwide in 2024, the annual number of installations in 2026 is expected to increase to 718,000.

The KUKA Group launched mosaixx in 2024 to provide an open, collaborative cloud platform for industrial software for this growing field. It provides system integrators and engineers with access to a wide range of solutions to drive the digitalization and automation of factory floors and production machines using an ecosystem approach, regardless of machine type or manufacturer.

Dassault Systèmes’ 3DEXPERIENCE platform and applications are used across the industrial equipment industry worldwide to design, simulate and engineer products, processes and infrastructure virtually with real-time data, before producing or implementing them physically.

www.3ds.com