www.magazine-industry-usa.com

30

'25

Written on Modified on

NORD Showcases Robust, Reliable Grain Industry Solutions at GEAPS Exchange

NORD’s solutions for the grain industry are engineered for reliability, high performance, and durability in harsh operating conditions.

NORD’s versatile solutions keep the grain industry moving with safe, reliable operation.

NORD DRIVESYSTEMS, a globally active provider of robust, reliable drive technology, is set to exhibit at GEAPS Exchange 2025, the grain industry’s largest show for industry professionals. The convention is being held at the Kansas City, Missouri Convention Center from February 22 – 25, 2025 and is the best place to see NORD’s innovative grain industry solutions in person. They provide highly configurable, specialized solutions with output torques up to 2,495,900 lb-in to efficiently power bucket elevators, drag and belt conveyors, screw conveyors, rotary valves, feeders, slide gate, silo reclaimers, and more. All NORD drive solutions are designed to be durable, versatile, efficient, and intelligently controlled to accommodate a wide range of grain and bulk material handling applications.

NORD showcases these featured products at GEAPS Exchange Booth 626:

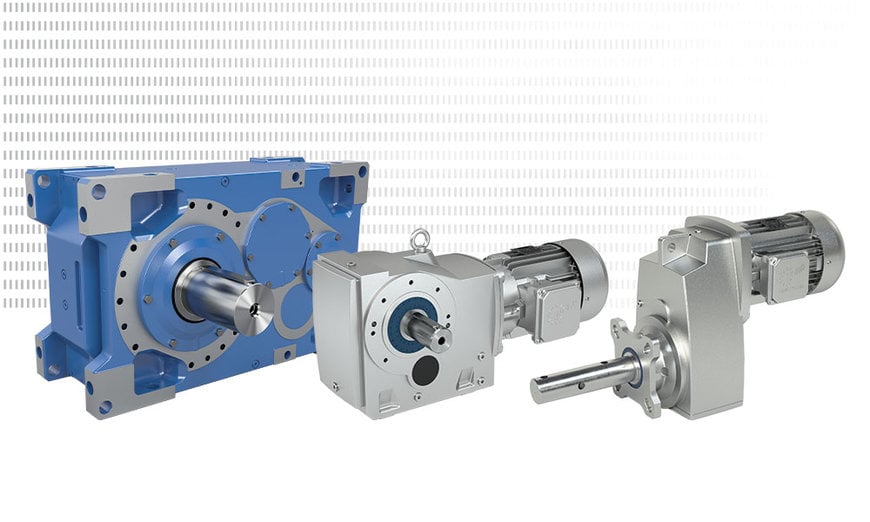

MAXXDRIVE Industrial Gear Units

MAXXDRIVE® industrial gear units deliver torques up to 2,495,900 lb-in making them ideal for use in heavy-duty grain applications such as bucket elevators, mixers, conveyor belt drives, mills, drums, and more. Available in 11 case sizes with right-angle and parallel shaft designs, MAXXDRIVE gear units are highly versatile with long service life, quiet operation, and low maintenance. For applications like bucket elevators, special sealing solutions, back stops, fluid couplings, and swing bases are available to meet application needs. They additionally offer extensive input options, mounting options, add-on modules, cooling and heating options for temperature management, and safety measures to protect operators as well as equipment.

MAXXDRIVE XT industrial gear units are a two-stage, right-angle design ideal for high-speed applications. They feature a finned housing design that helps dissipate heat faster while an axial fan and air guide covers enhance airflow, preventing the unit from overheating even at maximum power. These effective cooling abilities make them a reliable, robust solution for demanding grain industry environments where ambient conditions fluctuate. These industrial gear units are able to be arranged in a symmetrical configuration for mirror image installations and can be mounted with a motor on a swing base where needed.

MAXXDRIVE units also have the option of adding a Grain Endurance Package, a comprehensive set of protective measures that optimize performance, maintain reliability, simplify maintenance, and extend longevity of drive components in harsh environments. The main features of the package consist of a drying agent filter, oil sampling port, filter cart quick disconnects, oil level inspection sight glass, and an oil drain valve. These options are packaged together in one convenient solution specially configured to meet the demands of the grain industry.

UNICASE Helical Bevel Gear Units

UNICASE helical bevel gear units are made with a robust, cast-iron housing that offers long-lasting gearing, high axial and radial load capacity, minimum backlash, and efficient performance, making them an ideal choice for drag or chain conveyors, rotary feeders, and small belt conveyors. Eleven case sizes and a variety of shaft and mounting options make the units highly adaptable to specific application requirements with integrated backstops to prevent material back flow in conveyor systems. These gear units additionally offer various heavy duty bearing and spread bearing/flange mount designs for increased load capacity and extended service life.

Electric Motors

NORD’s portfolio of synchronous and asynchronous electric motors are manufactured in-house according to strict quality guidelines and can be combined with all their gear units and electronic control products. These motors meet all common global efficiency regulations and standards, ranging from IE1 efficiency all the way up to IE5+ ultra-premium efficiency. They are engineered to operate reliably and safely in harsh environmental conditions, where extremely heavy loads are moved, or where there is a dust or gas explosion hazard. NORD’s motors are also highly configurable and include options such as brakes, IP66 protection, encoders, external cooling fans, thermal protection, temperature sensors, and more.

Screw Conveyor Package

The NORD Screw Conveyor Package is a compact, cost effective alternative to traditional screw conveyor drives available for UNICASE parallel shaft gear units and UNICASE helical bevel gear units. This innovative design directly couples a gear motor or NEMA C-face input and eliminates the need for top motor mounts, pulleys, belts, or guards, enabling easier system maintenance while increasing reliability, safety, and drive performance. An optimized sealing system with QUADRLIP™ seals protects the internal gearing from contaminants while a standard CEMA mounting flange with multiple bolt patterns offers versatility to application constraints.

Learn more about NORD’s grain industry solutions at GEAPS Exchange booth 626 or by visiting.

www.nord.com

NORD DRIVESYSTEMS, a globally active provider of robust, reliable drive technology, is set to exhibit at GEAPS Exchange 2025, the grain industry’s largest show for industry professionals. The convention is being held at the Kansas City, Missouri Convention Center from February 22 – 25, 2025 and is the best place to see NORD’s innovative grain industry solutions in person. They provide highly configurable, specialized solutions with output torques up to 2,495,900 lb-in to efficiently power bucket elevators, drag and belt conveyors, screw conveyors, rotary valves, feeders, slide gate, silo reclaimers, and more. All NORD drive solutions are designed to be durable, versatile, efficient, and intelligently controlled to accommodate a wide range of grain and bulk material handling applications.

NORD showcases these featured products at GEAPS Exchange Booth 626:

MAXXDRIVE Industrial Gear Units

MAXXDRIVE® industrial gear units deliver torques up to 2,495,900 lb-in making them ideal for use in heavy-duty grain applications such as bucket elevators, mixers, conveyor belt drives, mills, drums, and more. Available in 11 case sizes with right-angle and parallel shaft designs, MAXXDRIVE gear units are highly versatile with long service life, quiet operation, and low maintenance. For applications like bucket elevators, special sealing solutions, back stops, fluid couplings, and swing bases are available to meet application needs. They additionally offer extensive input options, mounting options, add-on modules, cooling and heating options for temperature management, and safety measures to protect operators as well as equipment.

MAXXDRIVE XT industrial gear units are a two-stage, right-angle design ideal for high-speed applications. They feature a finned housing design that helps dissipate heat faster while an axial fan and air guide covers enhance airflow, preventing the unit from overheating even at maximum power. These effective cooling abilities make them a reliable, robust solution for demanding grain industry environments where ambient conditions fluctuate. These industrial gear units are able to be arranged in a symmetrical configuration for mirror image installations and can be mounted with a motor on a swing base where needed.

MAXXDRIVE units also have the option of adding a Grain Endurance Package, a comprehensive set of protective measures that optimize performance, maintain reliability, simplify maintenance, and extend longevity of drive components in harsh environments. The main features of the package consist of a drying agent filter, oil sampling port, filter cart quick disconnects, oil level inspection sight glass, and an oil drain valve. These options are packaged together in one convenient solution specially configured to meet the demands of the grain industry.

UNICASE Helical Bevel Gear Units

UNICASE helical bevel gear units are made with a robust, cast-iron housing that offers long-lasting gearing, high axial and radial load capacity, minimum backlash, and efficient performance, making them an ideal choice for drag or chain conveyors, rotary feeders, and small belt conveyors. Eleven case sizes and a variety of shaft and mounting options make the units highly adaptable to specific application requirements with integrated backstops to prevent material back flow in conveyor systems. These gear units additionally offer various heavy duty bearing and spread bearing/flange mount designs for increased load capacity and extended service life.

Electric Motors

NORD’s portfolio of synchronous and asynchronous electric motors are manufactured in-house according to strict quality guidelines and can be combined with all their gear units and electronic control products. These motors meet all common global efficiency regulations and standards, ranging from IE1 efficiency all the way up to IE5+ ultra-premium efficiency. They are engineered to operate reliably and safely in harsh environmental conditions, where extremely heavy loads are moved, or where there is a dust or gas explosion hazard. NORD’s motors are also highly configurable and include options such as brakes, IP66 protection, encoders, external cooling fans, thermal protection, temperature sensors, and more.

Screw Conveyor Package

The NORD Screw Conveyor Package is a compact, cost effective alternative to traditional screw conveyor drives available for UNICASE parallel shaft gear units and UNICASE helical bevel gear units. This innovative design directly couples a gear motor or NEMA C-face input and eliminates the need for top motor mounts, pulleys, belts, or guards, enabling easier system maintenance while increasing reliability, safety, and drive performance. An optimized sealing system with QUADRLIP™ seals protects the internal gearing from contaminants while a standard CEMA mounting flange with multiple bolt patterns offers versatility to application constraints.

Learn more about NORD’s grain industry solutions at GEAPS Exchange booth 626 or by visiting.

www.nord.com