www.magazine-industry-usa.com

01

'24

Written on Modified on

DISCOVER STÄUBLI TECHNICAL WEAVING SOLUTIONS AT TECHTEXTIL NORTH AMERICA

Discover Stäubli’s cutting-edge technology for weaving technical textiles – come to Techtextil North America (20-22 August), at our booth in the German Pavillon in hall B, booth 1408.

At a time when engineering is constantly creating new and cutting-edge solutions that are lighter than ever and more robust, manufacturers are calling on the expertise of the textile industry for flat or 3D weaving of materials such as fiberglass, carbon or aramid. At the heart of Techtextil North America, Stäubli Textile will be presenting technical solutions that will have a resounding impact on the technical weaving industry.

Stäubli launched its new TF30 weaving machine at Techtextil Frankfurt earlier this year in April. Now visitors have the chance to learn more about this revolutionary machine. The TF30 enables weaving mills to produce new types of technical fabrics in sectors ranging from medicine to transportation, aerospace, and more.

Creating machinery for the production of fabrics that are essential to global innovation is what motivates and inspires our teams. Flexibility and support are prerequisites for weaving technical fabrics, especially with new materials and 3D forms. Partnering with customers, universities, and industries, and applying our decades of experience in R&D, we are constantly advancing our range of solutions and services.

TF30 weaving system – a new solution for 3D fabrics

This new Stäubli weaving machine boasts innovative and unique benefits. With variable-height rapier weft insertion, it provides never-before-seen flexibility in shed programming and in weave structure. The weft-insertion concept ensures gentle yarn treatment, so the system can handle carbon and aramid yarns as well as ultra-sensitive ceramic yarns. Mills can choose from a wide range of Jacquard machines and customized harnesses perfectly suited to their weaving application.

What do printed circuit boards, airbags, lightweight carpets, and paper production filters have in common?

These and many more technical fabric applications are woven with the support of Stäubli machinery.

- The SAFIR S32 automatic drawing-in machine is used by weaving mills around the world to produce PCB boards and glass applications.

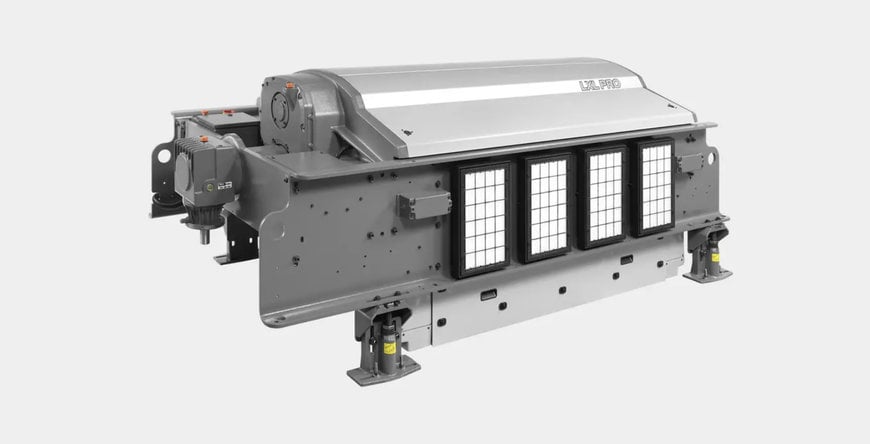

- The LXL PRO Jacquard machine provides features for one-piece woven (OPW) applications, including top-quality airbags in any format. Featuring NOEMI electronics architecture, this machine ensures a continuous Jacquard weaving process at the highest speeds and top energy efficiency. OPW weaving mills also use our TIEPRO warp-tying machine to achieve perfect knots with short ends that are easily passed through the reed, ensuring the proper order.

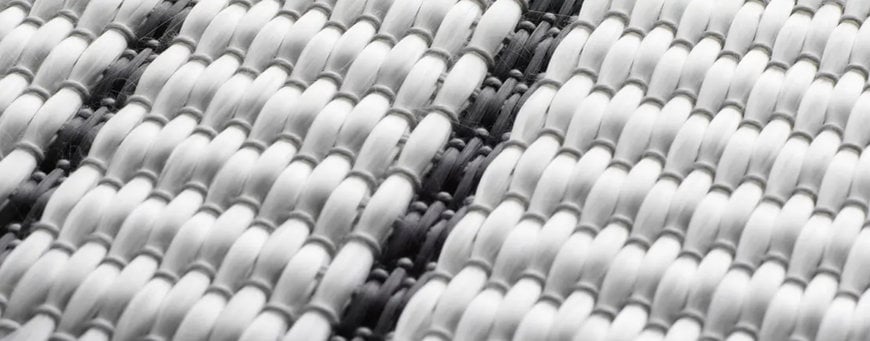

- The Stäubli ALPHA 500 LEANTEC weaving system provides features for extremely uniform and precise loops, needed for lightweight carpets for the transportation sector.

- Our heavy-duty dobbies for large frame weaving machines are renowned for their robust construction and their ability to withstand vibration encountered e.g. in the production of paper machine filters.

These are just a few examples of what weavers can achieve with the support of Stäubli solutions. With a broad range of equipment for producing technical fabrics, from flat to 3D, Stäubli answers the needs of the weaving industry.