www.magazine-industry-usa.com

25

'16

Written on Modified on

NSK to show products for high-speed, small-size applications at SIAMS 2016

NSK will be showing a range of its latest innovations for high-speed, small-size production technologies at the SIAMS exhibition in Moutier, Switzerland on 19-22 April.

SIAMS is dedicated to the extensive micro-manufacturing sector found in Switzerland, which centres on industries such as watchmaking and medical device production. As a result, NSK will present both miniature products and a range of suitable machine tool solutions at the show, with the company’s 60m² booth (C-18/D-21) in Hall 1.1 divided accordingly into two separate areas. Machine tool products will include precision bearings, linear guides, ball screw support bearings and linear actuators, among others.

Due to the high spindle speeds associated with many machine tools used in micro-machining applications, taking centre stage on the NSK booth will be the NSKROBUST BSR series of high-precision, small-size angular-contact ball bearings. With 100 years of bearing manufacturing experience to its name, NSK produces the BSR series using its proven material technology, evaluation and analysis capabilities, ensuring these highly functional bearings are able to support all types of high-speed spindles.

The BSR series offers good lubricity thanks largely to the counter-bore shape of both the inner and outer rings. In addition, the bearings are pre-greased as standard, and if required are available as sealed bearings in all sizes across the range.

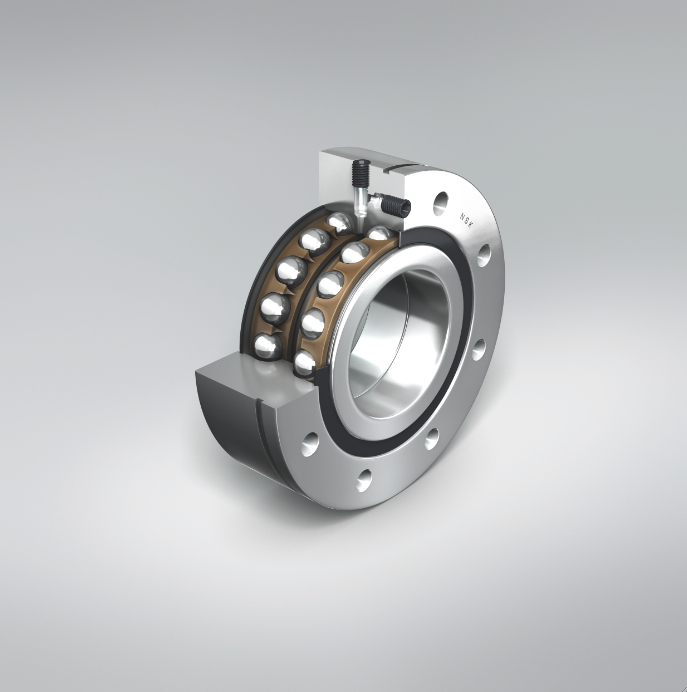

Further products in the spotlight at SIAMS will include NSK’s BSBD ball screw support bearings. Modern machine tools require ball screws that can accurately position a workpiece or machine component quickly and efficiently. The double row configuration of the BSBD series, with its 60° contact angle, enables the bearings to support large axial forces in both directions, while providing the accuracy and stiffness required by modern, high-precision machinery. The bearings feature a contact lip seal in the inner ring groove that delivers good sealing characteristics with low friction and heat generation. All BSBD series ball screw support bearings are supplied greased for life and ready for installation.

The BSF series bearings on display at SIAMS are part of the BSBD range. These double row, angular-contact thrust ball bearings feature an extended outer ring, with bolt holes for direct mounting. Furthermore, dedicated holes in the outside surface and face of the outer ring allow for re-lubrication during operation (the holes are closed off with set screws), while an extraction groove on the surface of the outer ring aids removal of the bearing.

Also at the show will be NSK’s Toughcarrier range of single-axis actuators, which now feature rollers as the rolling elements to enhance load capacity. The all-in-one structure of Toughcarrier units integrate a ball screw, linear guide and support unit to reduce design time, while the bottom and one side of the rail are datum surfaces to facilitate precision installation. Toughcarrier actuators are available in single and double slider variants, and in a variety of nominal rail widths, rail lengths and ball screw leads.

First established in 1989, SIAMS represents the entire production chain of micro-technology – from design and raw materials to production and assembly, components, the supply industry, and related activities. With this in mind, the biennial fair responds to the needs of SMEs that specialise in the fields of small and precision part production. Around 17,000 visitors and 450 exhibitors are expected at the 2016 event. Tickets are free of charge and available for download online at www.siams.ch/tickets.

NSK’s booth at SIAMS 2016 will focus on miniature products and machine tool solutions