www.magazine-industry-usa.com

06

'24

Written on Modified on

The first high-precision proportional valve terminal VTEP by Festo opens up new application areas

Controlled Pneumatics is the revolutionary compressed air technology from Festo that is opening up new perspectives for pneumatics.

Thanks to this technology, the pressure control of the compact proportional valve terminal VTEP is extremely sensitive, down to less than 1 mbar. This is perfect for applications such as wafer polishing or patch clamping in life science. In addition, Controlled Pneumatics uses high-precision piezo valves to reduce compressed air consumption by up to 50%.

VTEP, the first proportional valve terminal on the market, offers high precision, fast response times, and dynamic control. This speeds up production, and at the same time ensures that manufactured products are of a higher quality. This is how Festo makes machines and systems faster and more precise, and helps the electronics and semiconductor industries, textile manufacturing, battery production and life sciences, for example, to gain decisive competitive advantages.

Pressure or vacuum? Both!

At less than 120 mm wide, VTEP is the most compact proportional valve terminal on the market for pressure control with 10 working channels. There are three versions, 2-, 3- and 5-way, which can all be easily integrated for multi-channel applications. Pressure and vacuum can be combined in the control range of 6 bar.

The directly controlled VTEP uses piezo technology, which, together with the appropriate control technology, makes the pneumatics extremely precise, fast, and economical. This offers additional benefits: the valves are quiet, free of wear, have no particle abrasion, and don't generate any heat. The valve terminal is also free of copper, nickel, and zinc, making it very suitable for battery production and other industrial segments in which these materials are disruptive.

Wafers, batteries, and more

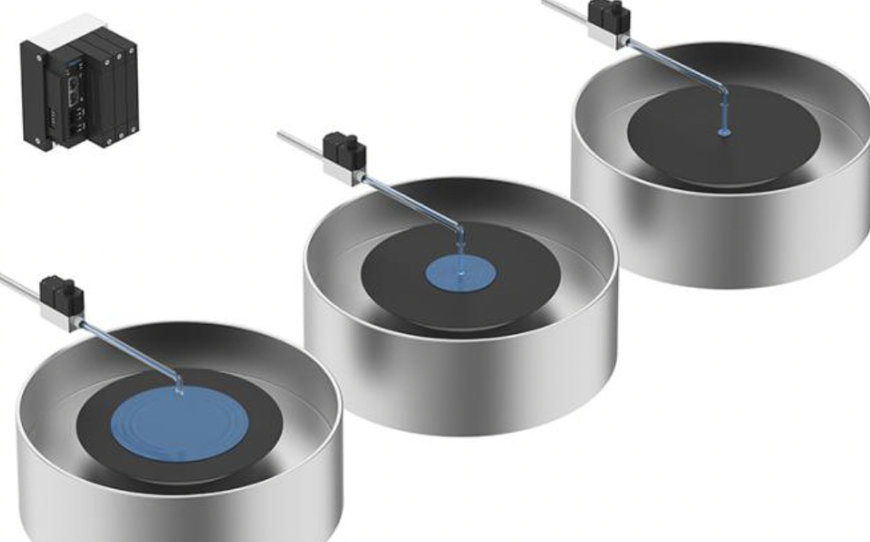

During wafer production, the variable contact pressure of the individual polishing chambers on the polishing unit is controlled extremely precisely by the VTEP using Controlled Pneumatics. The even pressure guarantees excellent results across the entire processing surface, even when polishing delicate wafers. Valve terminals type VTEP can also be used as pilot valves for media valves. In photolithography, for example, a light-resistant layer has to be precisely applied to wafers. A VTEP-controlled suck-back function ensures that no excess paint escapes.

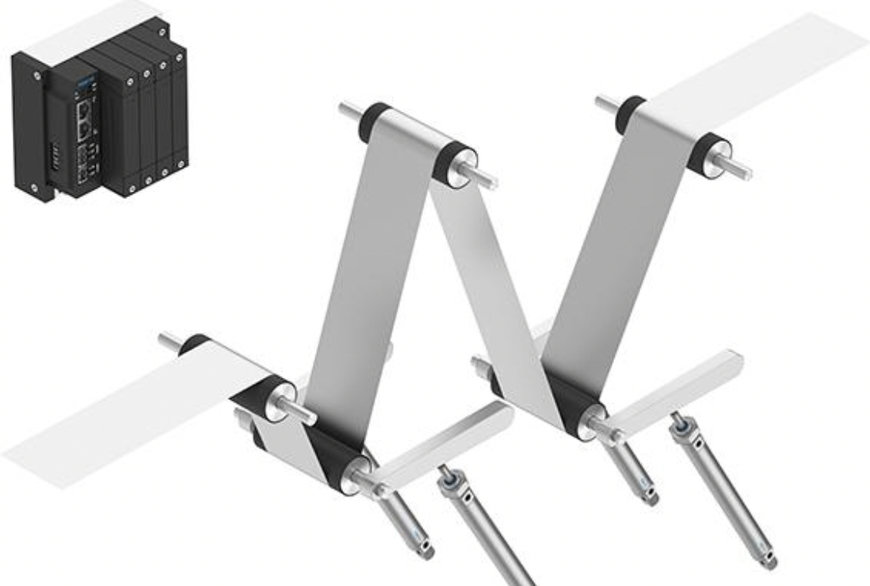

The proportional valve terminal VTEP is also suitable for many applications in web control, such as the production of battery foils. VTEP communicates virtually in real time, and the valves react at lightning speed. Perfect timing guarantees significantly improved process reliability in the event of unexpected forces.

www.festo.com