www.magazine-industry-usa.com

31

'24

Written on Modified on

INTEL OPENS FAB 9 IN NEW MEXICO

The opening marks a milestone for high-volume manufacturing of 3D advanced packaging technologies.

A drone photo shows Intel's new Fab 9 in Rio Rancho, New Mexico, in January 2024. (Credit: Intel Corporation)

Intel celebrated the opening of Fab 9, its cutting-edge factory in Rio Rancho, New Mexico. The milestone is part of Intel's investment to equip its New Mexico operations for the manufacturing of advanced semiconductor packaging technologies, including Intel’s breakthrough 3D packaging technology, Foveros, which offers flexible options for combining multiple chips that are optimized for power, performance and cost.

Intel’s global factory network is a competitive advantage that enables product optimization, improved economies of scale and supply chain resilience. The Fab 9 and Fab 11x facilities in Rio Rancho represent the first operational site for mass production of Intel’s 3D advanced packaging technology. It is also Intel's first co-located high-volume advanced packaging site, marking an end-to-end manufacturing process that creates a more efficient supply chain from demand to final product.

Fab 9 will help fuel the next era of Intel’s innovation in advanced packaging technologies. As the semiconductor industry moves into the heterogeneous era that uses multiple “chiplets” in a package, advanced packaging technologies, such as Foveros and EMIB (embedded multi-die interconnect bridge), offer a faster and more cost-efficient path toward achieving 1 trillion transistors on a chip and extending Moore’s Law beyond 2030.

Foveros, Intel’s 3D advanced packaging technology, is a first-of-its-kind solution that enables the building of processors with compute tiles stacked vertically, rather than side-by-side. It also allows Intel and foundry customers to mix and match compute tiles to optimize cost and power efficiency.

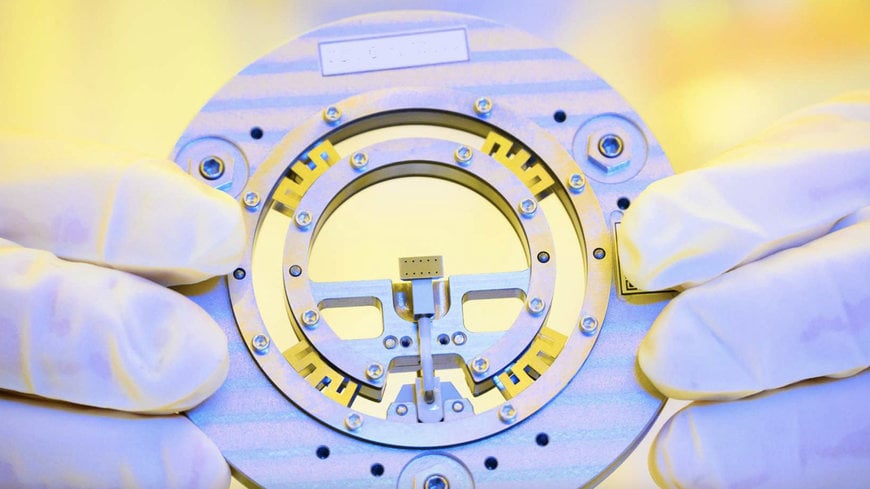

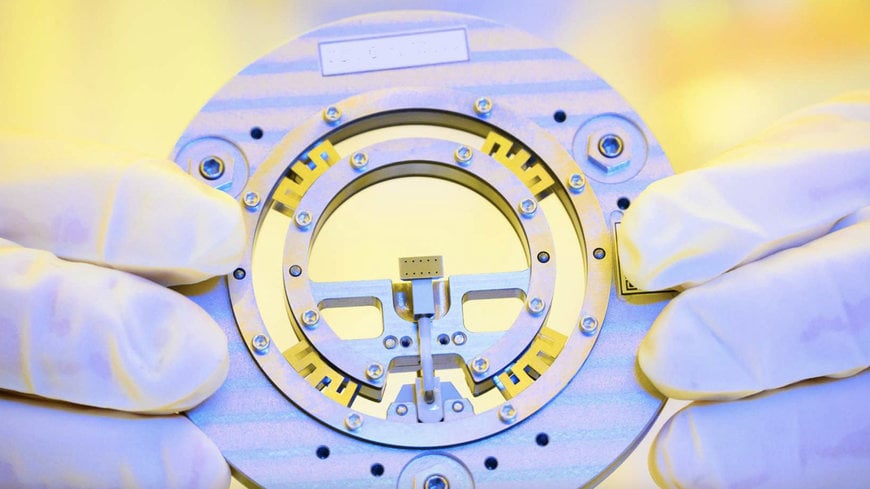

An Intel manufacturing technician at Fab 11x holds a bond module carrier containing a single silicon photonics chip. These Intel products enable future data centre bandwidth growth and next-generation 5G deployments using smaller form factors and higher speeds. (Credit: Intel Corporation)

www.intel.comIntel celebrated the opening of Fab 9, its cutting-edge factory in Rio Rancho, New Mexico. The milestone is part of Intel's investment to equip its New Mexico operations for the manufacturing of advanced semiconductor packaging technologies, including Intel’s breakthrough 3D packaging technology, Foveros, which offers flexible options for combining multiple chips that are optimized for power, performance and cost.

Intel’s global factory network is a competitive advantage that enables product optimization, improved economies of scale and supply chain resilience. The Fab 9 and Fab 11x facilities in Rio Rancho represent the first operational site for mass production of Intel’s 3D advanced packaging technology. It is also Intel's first co-located high-volume advanced packaging site, marking an end-to-end manufacturing process that creates a more efficient supply chain from demand to final product.

Fab 9 will help fuel the next era of Intel’s innovation in advanced packaging technologies. As the semiconductor industry moves into the heterogeneous era that uses multiple “chiplets” in a package, advanced packaging technologies, such as Foveros and EMIB (embedded multi-die interconnect bridge), offer a faster and more cost-efficient path toward achieving 1 trillion transistors on a chip and extending Moore’s Law beyond 2030.

Foveros, Intel’s 3D advanced packaging technology, is a first-of-its-kind solution that enables the building of processors with compute tiles stacked vertically, rather than side-by-side. It also allows Intel and foundry customers to mix and match compute tiles to optimize cost and power efficiency.

An Intel manufacturing technician at Fab 11x holds a bond module carrier containing a single silicon photonics chip. These Intel products enable future data centre bandwidth growth and next-generation 5G deployments using smaller form factors and higher speeds. (Credit: Intel Corporation)